-

Shunhua Road, Jinan City, Shandong

Laser Cleaning Solutions for Industrial Pipelines

Cut downtime and boost safety with BOGONG Laser’s industrial pipeline cleaning machines. Precise, eco-friendly, and built for global B2B with top certifications.

Keeping industrial pipelines clean isn’t just about looking good—it’s about safety, uptime, and cost. Dirt, rust, scale and residues build up over time. They choke flow, spur corrosion, and force shutdowns. Laser cleaning tackles these headaches head-on. It blasts contaminants away without touching the metal, so you avoid gouges or heat damage. In this article, we’ll explore key use-cases, compare tech, share real-world wins, and show you how BOGONG Laser’s factory-built machines deliver better ROI and greener operations.

Power Showdown: 200W vs. 300W Pulse Laser Cleaning Machines | 300W Fiber Laser Cleaning Machine

Let’s see the cleaning effect of 200W and 300W Pulse Laser Cleaning Machines.

You’ll see how the 300W unit removes rust faster, while the 200W unit deftly handles thinner films.

Why Laser Cleaning Works for Pipelines

Traditional grit blasting or acid baths? They demand lots of prep, toss toxic waste, and often scar the pipe. Laser cleaning uses high-energy beams to vaporize grime at the surface—no contact, no chemicals.

Precision Non-Contact Ablation

Lasers focus energy in micro-spots. They hit contaminants hard, then shut off before the metal heats too much. That selective ablation leaves base material intact. You get millimeter-level accuracy, even inside welds or tight bends.

Fast Setup, Minimal Downtime

A typical acid wash needs staging areas, drain lines, neutralization, disposal permits. Laser units roll up on wheels or hang from cranes. You point, fire, and move on. Most jobs finish in hours, not days, so you cut lost-production windows.

Critical Scenarios for Pipeline Cleaning

Pipelines serve many industries, each with its own kind of mess. Here a

re top cleaning scenarios—plus data on how pulse and CW systems perform.

Oil & Gas Flowline Descaling

Scale from minerals or paraffin can clog oil‑field lines. Field tests reveal that mid‑power fiber laser units clear away thin deposits almost instantly, while beefier setups handle stubborn buildups at a steadier pace. An enclosed skid, a vacuum truck and an inert‑gas purge work in concert to contain fumes and prevent any stray sparks.

Chemical Transport Lines

Acidic or caustic films eat away at fittings. A 200 W pulse laser wand can strip these without pitting the steel. You avoid harsh neutralizers and corrosion inhibitors.

Water Treatment & Power Plant Pipes

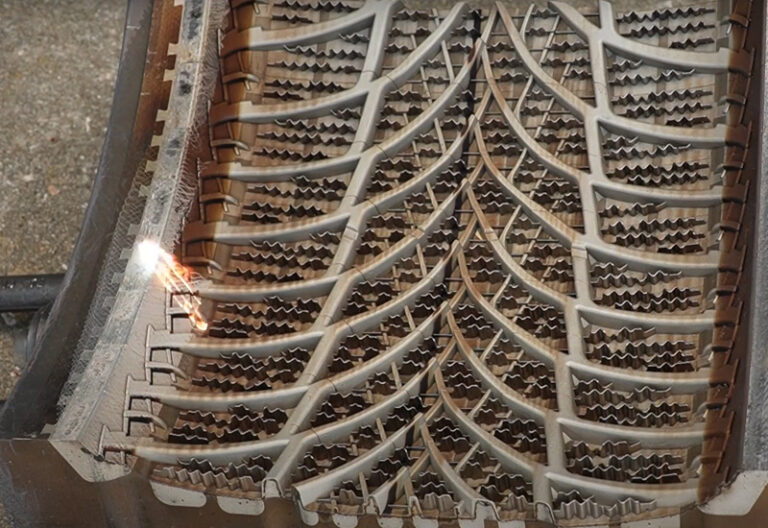

Biofilm, algae and mineral crust can foul heat‑exchanger tubes. Rotating galvo heads sweep along the inner walls at a brisk clip in narrow piping and at a more measured pace in larger bores—restoring flow without ever taking the system apart.

Pulse vs. CW Laser Cleaning for Pipelines

Not all lasers act the same. You’ve got two main flavors—pulse and continuous wave (CW).

Pulse Laser Mechanics

Pulse systems fire short, intense bursts. They shatter oxides in micro-seconds. That’s ideal for stubborn rust or paint. You focus energy, then let the metal cool before the next shot. It’s like a jackhammer at the microscopic level.

Portable Demo: Backpack Laser Cleaner

Watch the video demonstration of pulsed laser cleaning of pipes. It shows how a handheld wand cleans on-the-fly, even in tight bends.

CW Laser Mechanics

CW lasers deliver a steady stream of energy. They melt or vaporize lighter layers—ideal for delicate coatings or quick touch-ups. They produce less plasma, so your optics stay cleaner longer.

Choosing the Right Laser Cleaning Machine

Your pipeline’s diameter, deposit type, and site access dictate the gear. Below is BOGONG Laser’s lineup to match every scenario:

| Model | Key Feature | Ideal Scenario |

|---|---|---|

| 1000W Pulse Laser Cleaning Machine | Ultra-high throughput | Main trunklines, refineries |

| 500W Pulse Laser Cleaning Machine | Mid-range power | Offshore lines, mid-size networks |

| 200W Pulse Laser Cleaning Machine | Handheld, versatile | Tight spaces & small pipes |

| 300W Pulse Laser Cleaning Machine | Faster scan speed | Moderate scale & routine maintenance |

| CW Fiber Laser Cleaning Machine | Continuous delivery | Delicate coatings, soft films |

| Trolley Case Type Laser Cleaning Machine | On-the-move cleaning | Wide-area pipeline corridors |

World Wins with BOGONG Laser

Offshore Pipeline Scale Cleaning

A North Sea operator had heavy calcium buildup in 6″ flowlines. They rolled in our 500 W Pulse Laser Cleaning Machine. In two shifts, teams cut scale deposition by 95%—no diver entry or hot tapping. It cut permit lead time by 40%.

Power Plant Tube Rehab

In a Midwestern plant, welding slag clogged heat-exchanger tubes. A trolley-mounted CW Fiber Laser Cleaning Machine stripped the slag in situ. It reduced rebuild time from 72 h to 18 h. Staff raved: “It dont require acid wash or tube pulling.”