-

Shunhua Road, Jinan City, Shandong

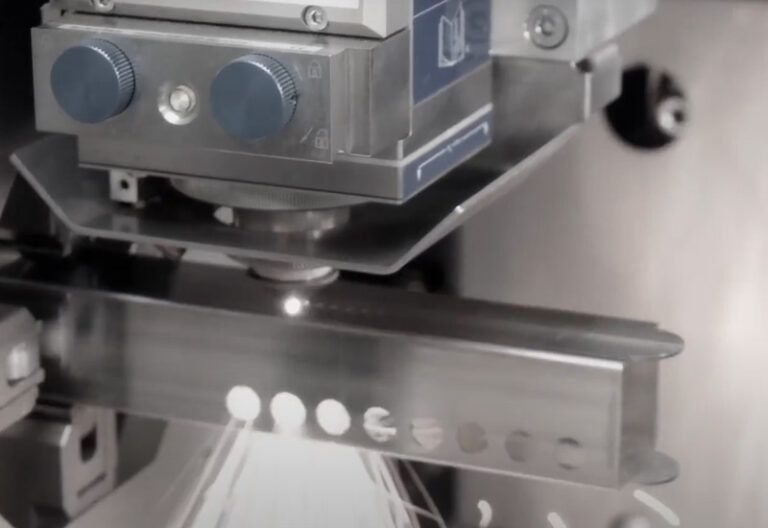

Fiber Laser Cutting Machine for Medical Ti Implants

Get clean, accurate cuts on medical Ti implants with fiber laser cutting machines. BOGONG LASER® helps you scale fast with high-precision CNC solutions.

Fiber laser cutting machines are suitabled for generating details and detailed cuts in titanium for medical implants as an outcome of their high accuracy, cost, and capability to lower heat-affected zones.This technology is essential for making aspects with limited resistances and complex geometries, such as stents, staples, and nitinol plates utilized in orthopedic and vascular implants.

Why Titanium Is Tricky—and Worth It

Titanium alloys, especially Ti6Al4V, are top-tier for implants since they’re corrosion-resistant, super solid, and do not flip out the body. However below’s the problem: titanium isn’t the easiest product to reduce. It reflects light, conducts heat weirdly, and forms a nasty burr if your cutting method’s off.

Conventional methods like EDM or waterjet might work, but they’re slow or messy. You want clean cuts without debris, deformation, or post-processing. That’s where fiber lasers steal the spotlight.

Fiber Lasers vs. Everything Else

Fiber laser cutting beats traditional methods in almost every category—speed, accuracy, cleanliness, and consistency. Here’s why that matters:

| Method | Cutting Speed | Cut Quality | Post-processing | Cost Over Time | Suitability for Medical Grade |

|---|---|---|---|---|---|

| EDM | Slow | Good | Required | High | Moderate |

| Waterjet | Moderate | OK | Required | Medium | Moderate |

| CO₂ Laser | Moderate | Not ideal | Often required | Medium | Low (titanium reflects CO₂) |

| Fiber Laser | Fast | Excellent | Minimal | Low | High |

With a fiber laser cutting machine, you’re not just cutting—you’re designing edge precision that passes medical-grade inspection. And you’re doing it fast.

What Makes Fiber Lasers Ideal for Medical Ti Implants?

Let’s get into what really makes fiber lasers tick in medical titanium cutting:

Micro-Precision

You need micron-level accuracy for implant shapes, especially things like spinal cages or knee parts. Fiber lasers deliver tight tolerances without deformation—even on ultra-thin sheets.

Low Heat-Affected Zone (HAZ)

With fiber lasers, you get focused energy input—so heat stays where it should, and nowhere else.

Clean, Burr-Free Edges

You don’t want to be grinding tiny edges off an implant. That’s time lost—and a contamination risk. Fiber lasers leave edges so clean you’d swear they were polished.

What’s Actually Happening on the Shop Floor

Medical device makers are using fiber lasers for:

Spinal implant cutouts with ± tight tolerances

Complex geometric bone plates

Perforated stents or cages

Ultra-thin titanium sheets for orthopedic use

For micro-implant parts, Grade 2 titanium sheets can be made astonishingly thin, and still hold their strength. Fiber lasers then carve them with such a refined finish that no polishing or grinding is ever needed. That means smoother, safer devices going inside the human body

Critical Cutting Parameters That Matter

Fiber lasers make it easy, but you still gotta tune the machine right. Operators in the field often tweak:

| Parameter | Effect on Cutting |

|---|---|

| Power level | Controls depth and speed |

| Cutting speed | Impacts burr formation and edge melt |

| Assist gas (Ar/N₂) | Reduces oxidation + cooling |

| Focus position | Keeps kerf width tight |

| Pulse modulation | Controls heat input on thin parts |

At BOGONG LASER, many Fiber Laser Cutting Machine models come with CNC auto-focusing. That’s a huge time-saver.

Let’s Talk Machines That Get the Job Done

Looking for the right machine for your medtech line? Here are a few solid options from BOGONG LASER’s portfolio, designed to handle Ti and thin sheet metal:

5050 Fiber Laser Cutting Machine: Compact but mighty. Great for smaller implant shops with precision needs.

- Bevel Fiber Laser Cutting Machine: When angled cuts and chamfering are needed—like for ergonomic implants.

Laser Plate & Tube Combo Fiber Laser Cutting Machine: Perfect if you’re doing both flat parts and tubular devices like bone screws or rods.

All machines are backed with OEM/ODM customization, multilingual support, and global certification (CE, FDA, ISO9001, SGS). That’s serious peace of mind if you’re shipping implants worldwide.

What Clients Actually Worry About (And How We Solve It)

If you’re in this space, you’re probably asking:

“Will the heat mess with my titanium’s structure?”

“Can I cut super-thin sheets without warping them?”

“How do I keep cutting consistent for 1,000 parts in a row?”

“Is the machine going to need baby-sitting 24/7?”

We get it. At BOGONG LASER, we work with metal shops, medtech factories, and implant suppliers in over 160 countries. We’ve seen it all. That’s why our machines include:

Stable cutting heads for nonstop batch runs

Smart CNC with repeat-programmable settings

Assisted cooling + inert gas options

Optional enclosures for dust-free cutting zones

So whether you’re cutting Ti rods for orthopedic plates or flat mesh stents, the system’s ready for cleanroom compliance, zero contamination, and minimal rework.

Commercial Value: Why Fiber Lasers Make Business Sense

Fiber lasers don’t just make your life easier—they slash costs in the long run.

Less manual cleanup = fewer labor hours

No consumables like blades or fluids = lower ops cost

Fewer rejected parts = better margins

Faster turnaround = more clients, faster deliveries

Let’s Make Precision Happen—Together

Want to know which fiber laser system fits your production best? Fill out the contact form at BOGONG LASER. We’ll walk you through your options.