-

Calle Shunhua, ciudad de Jinan, Shandong

Laser Welding Machine for Aluminum Radiator Assembly

Leak-tight aluminum radiator assembly with a Laser Welding Machine: practical setup, real floor fixes, and BOGONG LASER® support from factory to line—OEM/ODM ready.

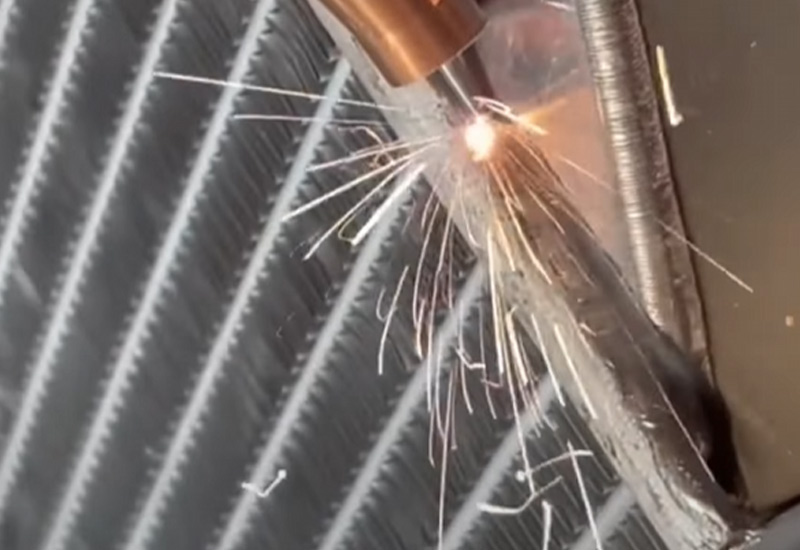

You build heat exchangers. Big ones, small ones, custom brackets, odd necks. Brazing does the heavy lifting on the core. A Laser Welding Machine steps in where assembly gets real: tanks, inlets/outlets, tabs, repair touch-ups, low-volume variants. Below is the straight talk—what works, what bites, and how to set up a cell that ships.

Where lasers fit in radiator work (and where they don’t)

Brazing owns the large surface joints inside the core. Laser wins on localized, leak-tight joints around the assembly:

Tank-to-header seam on aluminum radiator tanks

Necks, bosses, nipples (hose connections)

Brackets, tabs, studs and small reinforcement patches

Rework/repair where a brazed seam needs sealing, not re-running a whole furnace

Prototyping/variants when you don’t wanna spin a new brazing fixture

Quick vibe: laser = precise heat, low distortion, fast cycle. But aluminum is picky—reflective, high conductivity, likes to form pores. So your process has to be tight.

Example assembly moves that work

Close the gap with proper fixturing, leave a small root face.

Clean to shiny metal. No oil. No oxide layer.

Use Al-Si filler wire on sensitive alloys (crack risk? lower it).

Keep the shielding gas dry and consistent, consider mix gas for stubborn porosity.

Wobble or multi-spot to spread energy and calm the pool.

Monitor depth, then leak-test every part. No compromise here.

Pain points you may run into (and how to kill them)

| Problem on the floor | Root cause (most common) | Fix that gets results |

|---|---|---|

| Random pores (pinholes) | Moisture, unstable keyhole, poor gas cover | Dry gas path, better nozzle angle, consider Ar/He mix, reduce gap, steady travel |

| Hot cracking on 6xxx | Alloy sensitivity, too sharp thermal cycle | Switch to Al-Si filler, widen heat input window, tune wobble amplitude |

| Soot / dark haze | Contaminants, off-focus plume | Pre-clean, tweak focus height, add trailing shield |

| Underfill / concave bead | Too hot or too fast, no filler | Drop energy density a bit, slow a touch, add filler feed |

| Distortion on long seams | Over-constraint, uneven heat | Balanced clamping, stitch path planning, alternate start points |

| Leaks after test | Micro-porosity, missed tie-in | Add overlap at starts/stops, tune crater fill, raise gas flow just a bit |

The process recipe that actually ships parts

Fixturing & DFM

Design joints so the laser “sees” the seam. Keep consistent stand-off. Allow a channel for gas and wire. Clamp rigid, but don’t over-bend.

Surface prep

Degrease, light mechanical break on oxide, final wipe. If it looks gray and smeary, clean again. Shiny is right.

Energy & motion

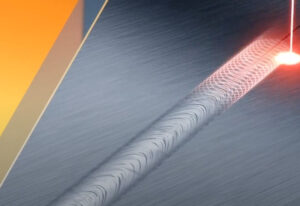

Keyhole mode for depth, wobble to widen the bead and calm the pool. Multi-spot (spot-in-spot) helps on long, flat seams where you need leak-tight + flat-ish surface.

Shielding

Argon works, but on pore-sensitive jobs a He blend smooths the pool. Keep hoses short, dry, and boring. Any hiss change? Stop and check.

Filler logic

Al-Si wire lowers crack risk on certain aluminum families. Don’t drown the pool; feed steady.

Inline quality

Depth monitoring (coaxial sensor), vision on seam, and leak test at the end. Save the data. Traceability is your friend when a batch comes back months later.

CAB vs. Laser at the assembly stage

| Topic | Brazing (CAB) | Laser on assembly |

|---|---|---|

| Scope | Core internals, big heat-spread joints | Tanks, necks, tabs, rework, variants |

| Heat load | Whole structure, uniform | Local, focused, low total heat |

| Changeover | Fixture-heavy | Program-heavy (fast), fixture light |

| Typical defects | Filler wash, non-wet areas | Porosity, hot cracking (controllable) |

| QC style | Process control + sampling | 100% monitoring + leak-test |

| Best use | High volume, stable BOM | Mixed models, custom, post-braze sealing |

Scenarios

Tank-to-header seam on a new variant

Engineering pushes a slightly different tank geometry. You don’t wanna re-tool the brazing fixture. Laser a perimeter seam with wobble + filler. Leak test. Ship. Later, if volume explodes, decide if you migrate upstream.

Neck replacement after a ding

A neck got knocked out during handling. Quick cut, prep, laser in a new boss. Gas cover tight, short cycle, back to line.

Bracket stack-up

Thin bracket on thin tank. Laser stitch in short runs to control distortion, then a final pass to seal. Less pull, nicer look.

What a lean laser cell looks like

Small robot or gantry, scanner head with wobble.

Wire feeder on a compact arm.

Dual-station fixtures (load one, weld one).

Gas cabinet with dry lines and flow check.

Inline depth monitor + camera.

Leak-tester next to unload.

Data log to your MES for traceability.

Keep the path steady, clamps repeatable, and gas boring. You’ll get stable beads that pass leak test without drama.

Picking the right tool from the catalog (and why)

If you’re setting up or expanding an assembly cell, handheld and compact units help you move fast, do pilots, and train crews. From BOGONG LASER®:

Soldadora láser manual — versatile gun-style tool for aluminum radiator assembly cells; great for brackets, nipples, small tank seams, on-the-spot rework.

Soldador láser manual 3 en 1 — weld/clean/cut in one body; useful when you need to prep oxides or trim a tab, then seal it right away.

Máquina de soldadura láser portátil con refrigeración por aire — handy when water cooling isn’t practical on the floor or you want lighter maintenance.

Mini máquina de soldadura láser 200W Pro con CCD — micro-features, precise visual alignment; think small bosses and delicate add-ons around the radiator frame.

Assembly do’s and don’ts (sticky-note level)

Do

Design joints for the beam. If the nozzle can’t see it, you can’t weld it.

Clamp evenly; leave a path for shielding gas.

Use filler on crack-sensitive materials.

Tune wobble to flatten the bead and cover the root.

Leak-test every part, save the results.

Don’t

Chase pores with more heat only. Fix gas, fit-up, and cleanliness first.

Assume one program fits all tanks. Small geometry changes, big pool changes.

Skip cleaning. Aluminum oxide is tough; it won’t just “burn off.”

Park the gas nozzle too far. Coverage matters more than you think.

Ignore starts/stops. Overlap them—crater cracks love edges.

Why BOGONG for radiator assembly

BOGONG LASER® builds and ships to Más de 160 países, supports OEM/ODM, and serves automotive, metalwork, electronics, signage and more. The site is multilingual, the install base is real, and the stack carries CE, ISO9001, SGS, FDA, France BV. We act like a Fábrica de máquinas de soldadura láser should: fast application support, clear fixtures advice, and practical process help. You can start with handheld units, then scale to more automated cells.

Also: our portfolio spans cutting, marking, cleaning, and welding. So when you need pre-clean + weld in one flow, you’re covered.

FAQ-ish reality bites

Can I bridge sloppy gaps? A little, with wobble and wire. Big gaps? Fix the fixture first.

Is helium a must? Not always. It helps with stubborn porosity. Try mixes before going full send.

Do I need depth monitoring? For leak-critical seams—yes. Saves scrap and arguments.

Handheld or robot? Start handheld to learn and iterate. Lock a robot when volume stabilizes.

Welcom to fill the contact form for BOGONG LASER® and we’ll get back fast.