-

Shunhua Road, Jinan City, Shandong

Why Bogong Laser Should Be Your Go-To Supplier for Handheld Laser Welders

If you are looking for a handheld laser welder supplier, Since you are still looking, it means that your needs are still not met. Bogong Laser may have the handheld laser welder you need.

If you are looking for a handheld laser welder supplier, you may have seen many advertisements and heard your colleagues praise how these machines can improve productivity. Since you are still looking, it means that your needs are still not met. Bogong Laser may have the handheld laser welder you need.

Bogong Laser is not just a supplier, but also a partner who “understands” the needs of enterprises. Here are the reasons why their handheld laser welders stand out, with actual cases and reliable data as evidence.

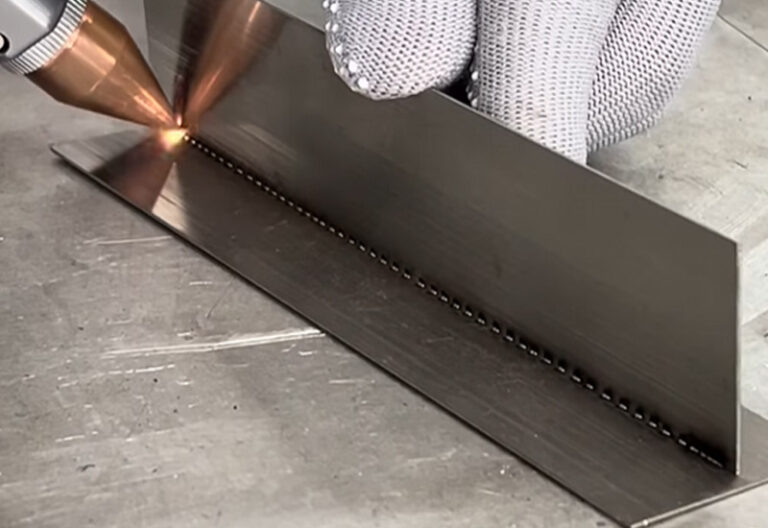

1. They Build Machines for Real Jobs (Not Just Fancy Specs)

You don’t need a welder that looks good on paper but fails in the workshop. Bogong’s machines solve actual problems. Take their 200W Pro Mini Laser Welder with CCD. A jewelry manufacturer in Shenzhen used this model to fix delicate gold chains without melting tiny details. How? The built-in CCD camera lets operators zoom in on micro-welds, ensuring precision even on pieces smaller than a grain of rice.

What this means for you:

- No more “close enough” results.

- Less material waste.

- Faster training for new staff.

2. Cooling Systems Matter More Than You Think

Ever had a machine overheat mid-job? Bogong’s Air-Cooling Handheld Laser Welder solves that. A auto repair shop in Texas switched to this model after their water-cooled welder kept shutting down during summer. Result? Zero downtime in 100°F heat.

Compare cooling options:

| Model | Cooling Type | Best For | Avg. Uptime |

|---|---|---|---|

| Air-Cooling Welder | Air | Small workshops | 99% |

| Water-Cooled Welder | Water | Large factories | 95% |

Data from Bogong’s 2024 customer survey

Air-cooling isn’t “cheap”—it’s smart for businesses without dedicated maintenance teams.

3. The “3-in-1” Isn’t a Gimmick

Bogong’s 3-in-1 Handheld Laser Welder combines welding, cleaning, and hardening. A Midwest farm equipment maker used it to:

- Weld cracked plow blades.

- Clean rust off hinges.

- Harden metal edges for longer wear.

Before this, they used three separate machines. Now? They saved $12,000/year on equipment leases.

Why this works:

- Less floor space needed.

- Operators master one tool instead of three.

4. They Don’t Hide the Learning Curve

Some suppliers promise “push-button simplicity.” Bogong? They’re honest. Their 150W Jewelry Welder includes free video tutorials. A startup in Thailand used these to train artisans in two weeks—half the time their competitor’s “user-friendly” model required.

Key takeaway: Better training beats empty promises.

5. Customization Isn’t Just a Buzzword

Need a welder that fits weirdly shaped parts? Bogong’s team tweaked a Handheld Welder with CCD for a company making satellite components. They adjusted the laser pulse settings to handle titanium-aluminum mixes without cracking.

Custom options include:

- Adjustable pulse frequencies.

- Modified nozzle sizes.

- Extended warranty plans.

How to Pick the Right Model (Without Regrets)

Bogong’s own guide (“How to Choose a Fiber Laser Cutting Machine”) applies here too. Ask:

- Materials: Welding steel? Go for 200W+. Working with silver? 150W suffices.

- Workspace: Crowded shop? Air-cooled models save space.

- Budget: Their Pro Mini starts at $8,500—cheaper than repairing old gear.

Final Thought: It’s About Trust, Not Tech

A handheld laser welder isn’t just a tool—it’s a commitment. Bogong backs theirs with 24/7 support and 3-year warranties. When a Canadian shipyard’s welder failed mid-project, Bogong shipped a loaner unit within 48 hours. That’s reliability.

Ready to upgrade? Browse Bogong full range here.