-

Shunhua Road, Jinan City, Shandong

The Best Vision Positioning Laser Marking Machine

Tired of slow, inaccurate laser marking? Our vision positioning systems automate alignment for perfect results on any part, boosting speed and cutting production costs.

Let’s be real. If you’re in the business of making things, you’ve probably felt the headache of marking or engraving them. You line up a part perfectly, run the job, and the logo is just a little bit off. Or you’re marking thousands of tiny components, and the sheer time it takes to place each one in a custom jig is killing your production schedule. It’s frustrating, it’s slow, and every mistake costs you money.

What if you could just… not do that anymore?

What if you could dump a tray of parts onto your machine, press a button, and have every single one marked with perfect accuracy, no matter how they’re oriented?

That’s not a far-off dream; that’s exactly what a Vision Positioning Laser Marking Machine does. It’s a straightforward upgrade that completely overhauls your workflow. At BOGONG Laser, we’ve seen this technology solve some of the most persistent problems in manufacturing, and today, we’re going to break down exactly how it works and why it might be the smartest investment you’ll make this year.

What Is a Vision Positioning Laser Marking System?

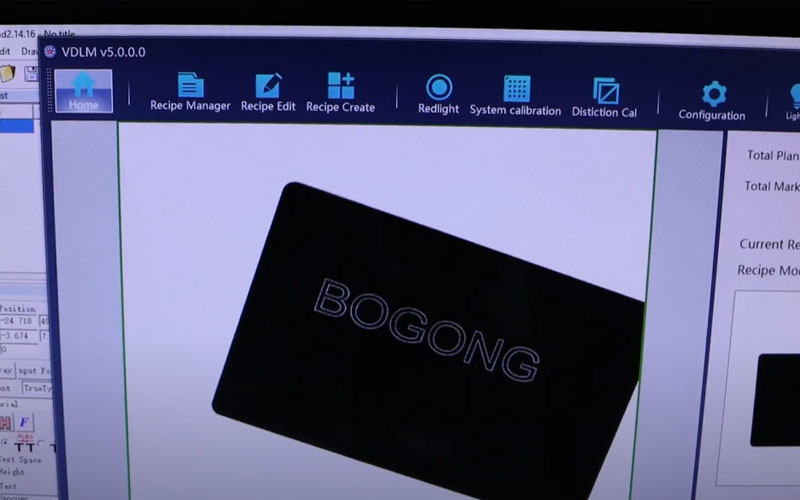

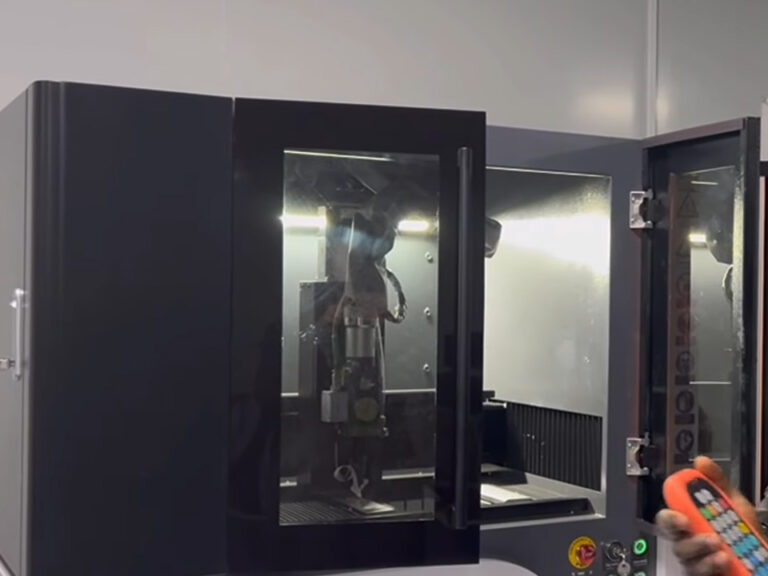

Think of it this way: we combined a high-resolution camera with a high-precision laser. The camera acts as an intelligent eye. Instead of you needing a physical jig or fixture to hold a part in a specific spot, the camera simply looks at the part. It identifies the product, finds its exact position and angle, and then tells the laser, “Okay, mark it right here.”

This all happens in a fraction of a second. For the operator, the process becomes incredibly simple: place the part (or parts) anywhere within the machine’s work area and hit “start.” The machine handles the rest.

The Old Way: Why Traditional Marking Is a Bottleneck

Before we dive deeper into the solution, let’s acknowledge the pain points you’re likely all too familiar with. Traditional marking methods, whether with a fiber, CO2, or UV laser, have always been held back by one thing: the need for precise, manual alignment.

- Custom Jigs for Everything: Every new product means designing, manufacturing, and storing a new custom fixture. This adds cost, complexity, and lead time. If you have a high mix of products, your workshop can quickly fill up with expensive jigs you barely use.

- Operator Skill and Time: Getting consistent results depends heavily on the skill of the operator. They have to carefully place each item, which is slow and mind-numbing work. This skilled labor could be used for more valuable tasks.

- High Scrap Rate: A slight bump, a misaligned part, a tired operator—any of these can lead to a scrapped part. When you’re working with expensive materials or nearly-finished goods, these mistakes add up fast.

- Inability to Scale: How do you speed up a process that relies on one-by-one manual placement? You can’t, not without hiring more people and buying more machines. It’s a production bottleneck that limits your growth.

The New Way: How Vision-Guided Marking Changes the Game

This is where the magic happens. By adding a vision system, you eliminate every single one of those problems.

Boost Your Production Speed Instantly

This is the most immediate benefit. Forget placing parts one at a time. You can now load a full tray of components, and the system will automatically find and mark each one in sequence. We’ve seen clients go from marking 5 pieces a minute to marking 50. This isn’t just a small improvement; it’s an order-of-magnitude leap in throughput. For high-volume industries like electronics or consumer goods, this is a total workflow transformation.

Achieve Pinpoint Accuracy Every Time

Human eyes are good, but they can’t compete with a computer. A vision system can detect positioning with micron-level accuracy (think ±0.001mm). It doesn’t matter if the part is slightly rotated or off-center. The software compensates automatically. This means your branding, serial numbers, and data codes are perfectly placed on every single item, ensuring consistency and quality that manual alignment can never match.

Slash Your Operating Costs

This technology pays for itself, often much faster than you’d expect. Here’s how:

- Zero Jig Costs: You can officially stop spending money and time on creating custom fixtures.

- Reduced Labor: You no longer need a skilled operator dedicated to tedious alignment. One person can easily oversee multiple machines, freeing up your team for more complex work.

- Minimal Waste: By eliminating positioning errors, you dramatically reduce your scrap rate. The machine marks the right spot, on the right part, every single time.

Unmatched Flexibility for Any Job

Your business needs to adapt quickly. With a vision positioning system, it can. Switching from one job to another is as simple as loading a new file in the software. The system learns the new part, and you’re ready to go in minutes. This is ideal for shops that handle a wide variety of products or custom orders. It doesn’t matter if the part is round, rectangular, or a completely irregular shape—if the camera can see it, the laser can mark it.

Traditional Marking vs. Vision-Guided: A Quick Breakdown

| Feature | Traditional Marking | BOGONG Vision Positioning Solution |

| Positioning | Requires manual alignment and custom-made physical jigs. | Automatic camera recognition; no jigs needed. |

| Efficiency | Slow, one-by-one processing. A major production bottleneck. | High-speed batch processing. Place parts freely and let the machine work. |

| Accuracy | Dependent on operator skill; prone to error and inconsistency. | Computer-driven precision (±0.001mm). Perfect results every time. |

| Cost | High costs for custom jigs, skilled labor, and scrapped parts. | Lowers costs by eliminating jigs, reducing labor, and minimizing waste. |

| Flexibility | Switching jobs is slow and requires new tooling. | Change jobs in minutes via software. Easily handles any shape or size. |

See It in Action

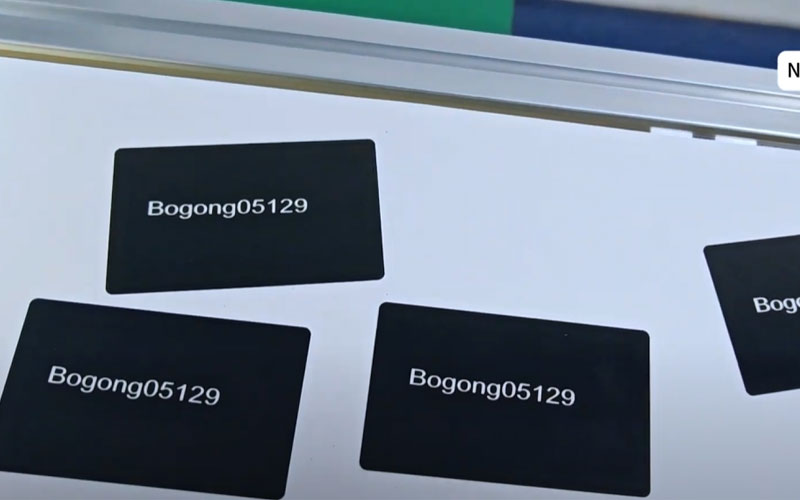

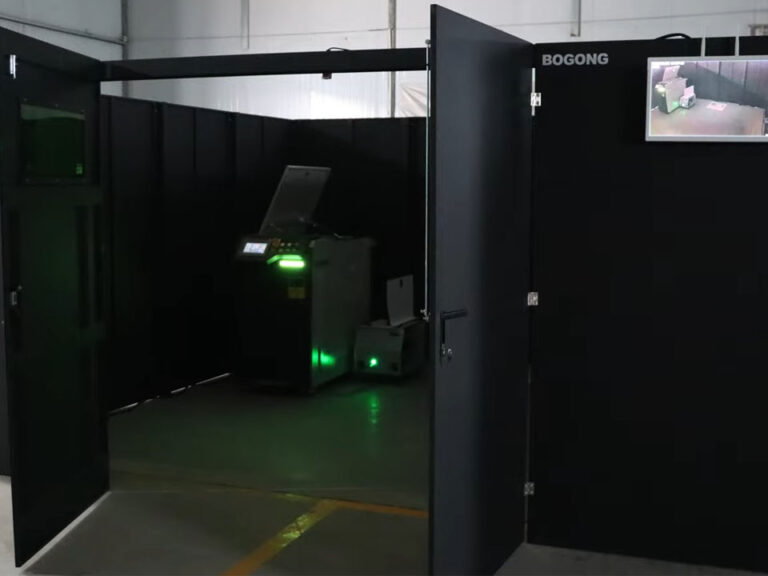

It’s one thing to read about it, and another to see it. This video shows a BOGONG Laser Vision Positioning system at work. Notice how the parts are placed randomly—the machine does all the hard work of finding and marking them.

[/vc_column_text][cz_gap height=”30px”][vc_video link=”https://youtu.be/VfZtrNHsVUw” css=”” title=”BOGONG MACHINERY Vision Positioning Laser Marking Machine”][cz_gap height=”10px”][vc_column_text css=””](Video Description: BOGONG MACHINERY Vision Positioning Laser Marking Machine in operation)

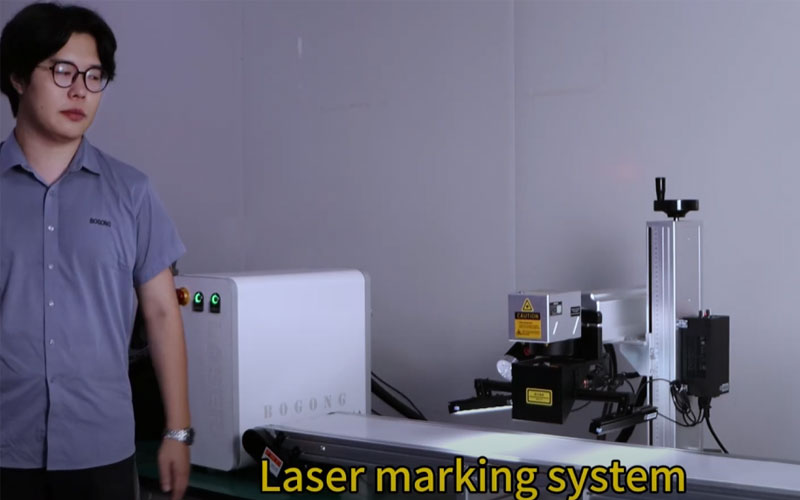

Which Laser Is Right for Your Material?

A vision system is the “brain,” but the laser itself is the “tool.” Choosing the right type of laser is critical and depends entirely on the materials you work with. At BOGONG Laser, we integrate vision positioning with our full range of markers.

Fiber Laser Marking Machine: The Metal Workhorse

If you’re marking metals (like stainless steel, aluminum, brass, titanium) or most hard plastics (like ABS, PEEK), the 30W Fiber Laser Marking Machine is your go-to solution. It’s incredibly durable and creates sharp, high-contrast marks that last forever. This is the top choice for automotive parts, medical devices, tools, and promotional products.

CO2 Laser Marking Machine: For Organics and Non-Metals

When your work involves materials like wood, acrylic, leather, glass, paper, or textiles, you need a CO2 Laser Marking Machine . The CO2 laser’s wavelength is absorbed well by these organic materials, creating a clean, engraved mark without burning. It’s perfect for custom branding on packaging, personalizing leather goods, or etching designs into wood and glass.

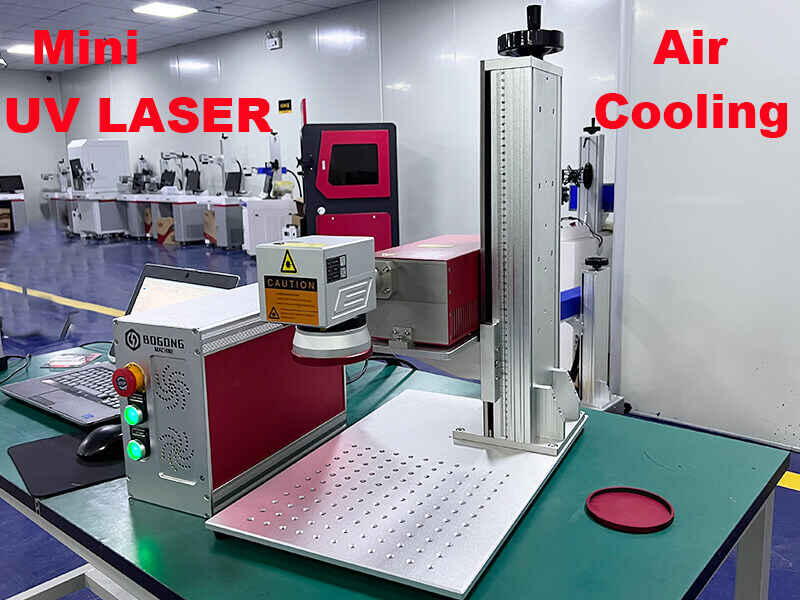

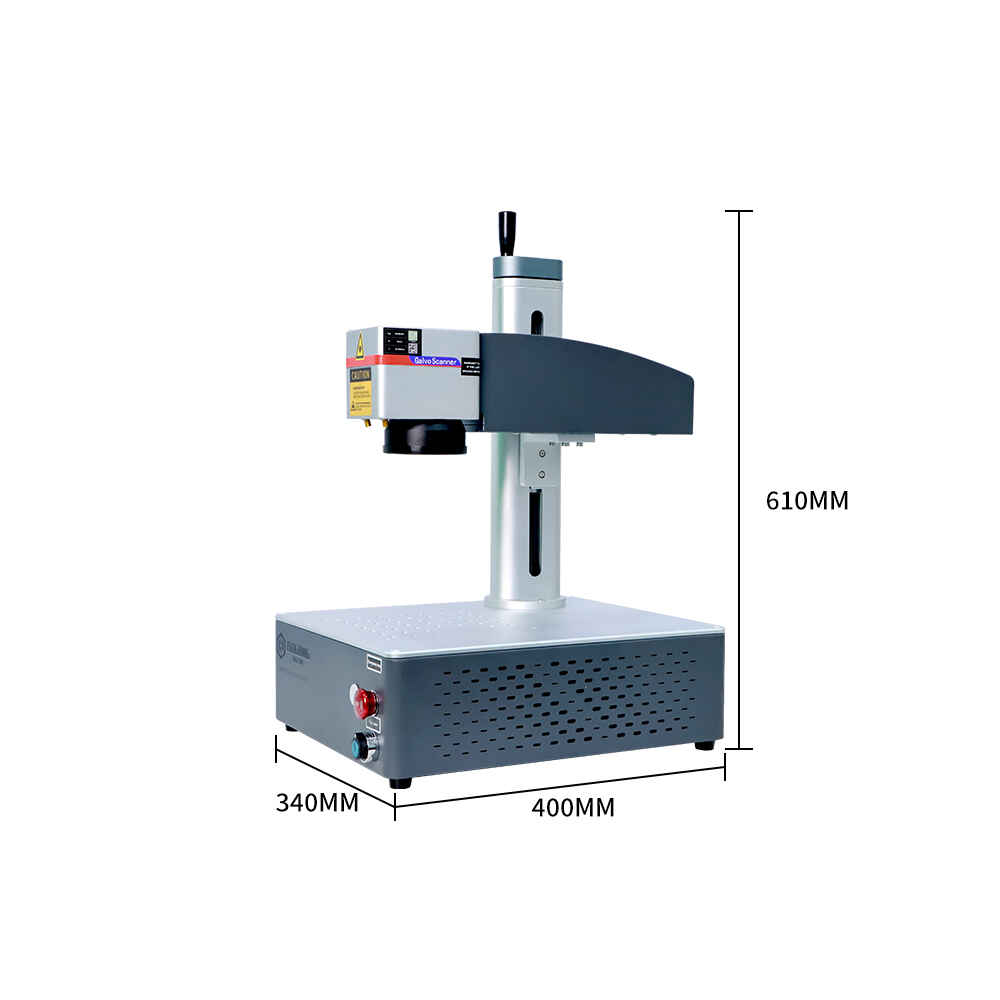

UV Laser Marking Machine: The “Cold Marking” Specialist

What about sensitive materials? Some plastics, silicones, and types of glass can be damaged by the heat generated by Fiber or CO2 lasers. That’s where a UV Laser Marking Machine comes in. It uses a “cold” marking process that breaks molecular bonds without generating heat. This prevents melting, foaming, or cracking, making it the only choice for marking delicate electronics, cables, and certain medical-grade plastics.

Real-World Scenarios, Real-World Value

This technology isn’t just for niche applications; it’s being used across every major industry to solve real problems. You can explore a wide range of uses on our Laser Marking Machine Application page. Here are a few common examples:

- Electronics: Imagine marking thousands of tiny capacitors on a PCB board. With vision, a tray of boards is processed in minutes, with serial numbers and logos marked perfectly on each component.

- Medical: Traceability is non-negotiable. Surgical instruments made of stainless steel require unique device identification (UDI) codes. A vision-guided fiber laser can mark these codes cleanly inside a tiny, pre-existing recess without fail.

- Jewelry: Engraving a hallmark or a custom message inside a ring used to be a delicate, skilled task. Now, a Fiber Laser Engraving Cutting Machine For Metal Jewelry with vision can instantly locate the engraving area on any ring size and apply the mark flawlessly.

- Automotive: Parts like pistons, valves, and brake pads need tracking codes. These parts are often irregularly shaped and come down the line quickly. A vision system identifies the part and marks it on the fly, keeping the production line moving.

Why Choose BOGONG Laser?

We know you have options. BOGONG Laser has been a professional CNC laser manufacturer for over a decade, and our focus is on delivering robust, reliable machines that provide immediate value. With over 9,000 clients in more than 160 countries, we have the global experience to understand your needs.

Our machines are built to last and are certified with CE, FDA, and ISO9001 standards, ensuring they meet the highest levels of quality and safety. But more importantly, we partner with you to find the right solution. Whether it’s a compact All-in-One Laser Marking Machine for a small workshop or a fully integrated system for an automated production line, our team is here to help you succeed.