-

Shunhua Road, orașul Jinan, Shandong

3 in 1 Handheld Laser Welder Cleaner Cutter for Field Repairs

3-in-1 handheld for field fixes—weld, clean, cut in one head. Practical tips, checklists, and BOGONG LASER options from a Laser Welding Machine Manufacturer.

A 3-in-1 handheld laser—weld, clean, cut—keeps you right there at the fault line and gets the joint fixed, surface cleaned, edge trimmed.

Why a 3-in-1 makes sense on-site

When a bracket, handrail, thin cover, or enclosure needs quick attention, swapping between grinders, solvents, and a separate cutter wastes time and kills focus. A single handheld laser head lets you stitch the crack, buff the oxide/paint off the heat-tint, and nibble a notch for fit-up—all without packing three machines. Less gear, fewer trips, more uptime.

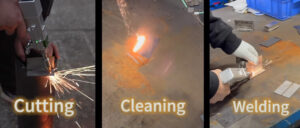

What it really does

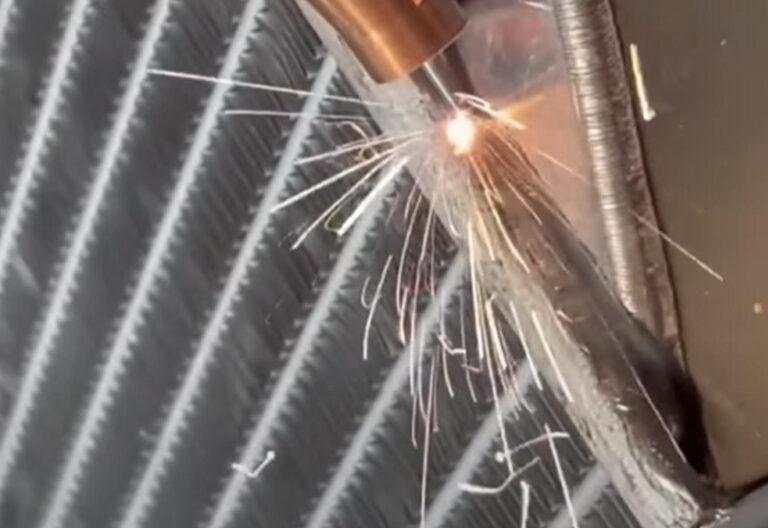

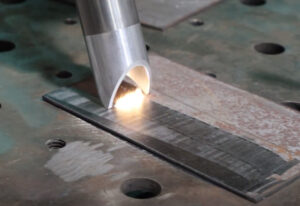

Welding — short runs, tight corners, solid finish

Handheld laser welding excels at short seams, patch repairs, and spot-by-spot build-ups where you can control heat input, keep the HAZ small, and avoid blowing out edges. It’s friendly to thin sheet and medium gauge parts when your prep is right: fit-up snug, root gap managed, shielding gas on point. Need a field-ready option? Check the Sudor laser portabil 3 în 1 and the portable Mașină de sudură laser portabilă from BOGONG LASER.

Cleaning — pre-clean for quality, post-clean for looks

“Welds don’t fail, prep does.” That’s why laser cleaning matters. Before welding, you chase off oil, oxide, light rust, paint. After welding, you lift the heat tint and surface blush so QA won’t ping you. No chemicals, no media blasting on delicate zones. Just sweep the beam, watch the surface brighten, then weld or sign off.

Cutting — trim, notch, and move on

Handheld cutting isn’t your long production cut. It’s for quick trims, slot openings, relief notches, and edge tidy-ups. Think access windows, flange relief, panel corners. If you expect long straight cuts in thick stock, bring a dedicated cutter. For field repairs, “trim-and-go” is the sweet spot. Want lower logistics? An Mașină de sudură laser portabilă cu răcire cu aer reduces the support kit you carry.

Some patterns

Stainless handrail scuff and pinhole on a site lobby: clean the tint, pull a small pass, post-clean, blend. Done before the lift comes back.

HVAC bracket hairline near a roof curb: a quick notch for clearance, tack-tack, seal pass, wipe with cleaning mode so the painter won’t shout.

Light enclosure door doesn’t sit: trim a tab, bump the hinge line, post-clean the weld face so the gasket actually seals.

Food-grade guard: pre-clean to remove oxide and residues, weld with steady travel speed and proper gas coverage, post-clean for a bright finish that inspection will accept.

Core arguments (and what they mean on site)

| Claim | What it means on the ground | Why it convinces a buyer |

|---|---|---|

| One head, three modes (weld/clean/cut) reduces tool changes | Fewer trips to the van, less setup churn, faster hand-offs | Time saved beats carrying three machines |

| Tight heat control and small HAZ | Less distortion, cleaner edges, nicer pass appearance | Fewer reworks, faster sign-off |

| Cleaning before and after boosts weld quality and finish | Pre-clean lowers porosity risk; post-clean removes tint and residue | QC likes it, customers see it |

| Handheld cutting is for trims, not heavy production | Slotting, panel relief, edge nibbles on thin/medium | Right-tool-right-job clarity; no over-promising |

| Portable = field revenue | More “we come to you” jobs, not just shop work | Extra billable service lines |

Field checklist

| Item | What to check | Sfat profesional |

|---|---|---|

| Putere | Stable single-phase where allowed; no sketchy leads | Keep cable runs tidy; voltage dips = ugly arcs |

| Shielding gas | Flow stable; nozzle angle right; back purging if needed | Gas coverage cures many sins |

| Fit-up | Root gap controlled; clamps or magnets in place | Bad fit-up = chasing porosity |

| Surface | Pre-clean oxide, paint, oil, scale | “Shiny then weldy” is the rule |

| Optics | Nozzle and lens clean; spatter shield in | A foggy lens ruins travel speed |

| Wind/drafts | Block drafts; keep the gas umbrella | Mobile screens save welds |

| Siguranță | PPE, fume extraction, light guards, LCA discipline | Laser = Class 4. Treat it serious |

Troubleshooting in the wild

| Symptom | Likely cause | Fix fast |

|---|---|---|

| Sooty edge / dull bead | Gas coverage poor, angle off | Bump flow, tighten angle, shorten stick-out |

| Pinholes / porosity | Contamination, oil under oxide, root gap too loose | Pre-clean again, reduce gap, steady travel |

| Burn-through on thin sheet | Heat input too spicy, pause too long | Faster travel, weave less, cool between passes |

| Warping / pull | Overheating, clamping weak | Stitch sequence, stronger fixturing, alternate sides |

| Ugly tint after pass | Post-clean skipped or weak | One more cleaning sweep; keep moving |

| Glare/reflection scare | Mirror-like base metal, bad viewing angle | Shift stance, angle the head, strict PPE and screens |

When to reach for it

| Scenariu | 3-in-1 handheld? | Notes |

|---|---|---|

| Thin/medium sheet patch | Da | Pre-clean + short passes shine here |

| Guard rails, cabinets, kiosks | Da | Clips, hinges, small seams—perfect |

| Long heavy structural seam | No | Bring dedicated process and fixtures |

| Thick section with deep prep | Maybe | If access is small and you can prep smart |

| Cosmetic stainless touch-ups | Da | Pre/post clean, low spatter, neat finish |

| Endless straight cutting | No | Use the shop cutter; keep handheld for trims |

Buying logic

If you run field crews, you care about uptime, finish quality, and how quickly a tech can switch from prep to weld to tidy-up. That’s exactly where a 3-in-1 shines. Look for a Laser Welding Machine Manufacturer that builds real-world ergonomics into the torch, offers multilingual training, and backs you with spares and remote support. BOGONG LASER is a global Mașină de sudură cu laser partner—Mașină de sudură cu laser category covers handheld welders, 3-in-1 units, and cooling options. We’re a Laser Welding Machine Factory mindset with a service playbook: OEM/ODM capability, certifications that matter, and teams who understand metalwork, jewelry, automotive, signage, electronics, and craft shops.

If you want a no-nonsense walk-through, we’ll show you on real parts. Fill the BOGONG contact form, and field constraints—we call back fast.