-

Shunhua Road, Jinan City, Shandong

Pipe & Tube Fiber Laser Cutting Machine Manufacturers Support Customized Exporters

Maximize export efficiency with customizable Tube & Pipe Fiber Laser Cutting Machine solutions—automated loading, precision beveling, and tube-only cutting.

Why Custom Mods Matter for Metal Pipe Laser Cutting Machine Exporters

You’ve probably run into exports getting held up because the machine can’t handle odd tube sizes or special bevels. Nowadays, top metal pipe laser cutting machine manufacturers get that one-size-fits-all gear isn’t cutting it. They roll out modular chucks, bevel heads, and PLC recipes to nail every scenario—from tiny jewelry tubes to thick oil-field pipe. At BOGONG Laser, we’ve seen clients slash burr and dross trouble by tweaking their g-code “burn rate” right on the HMI.

Modular Design Meets Diverse Scenarios with Laser Cutting Machine Metal Tube

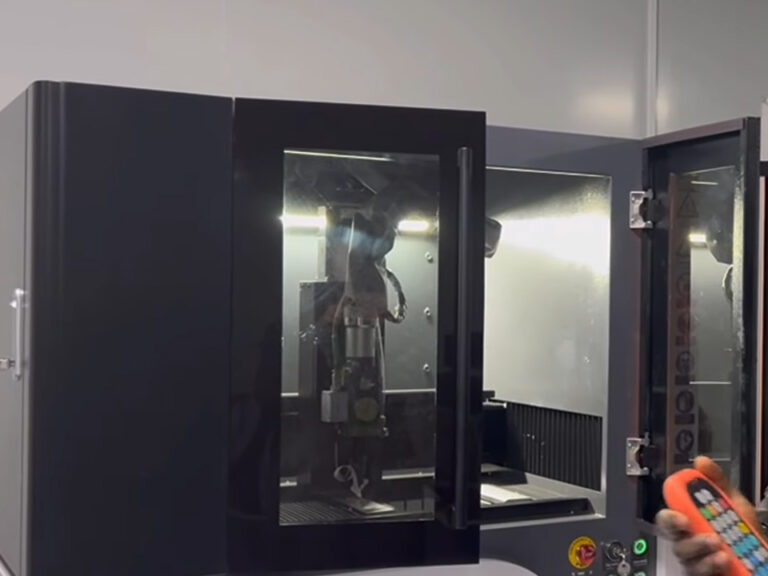

When you’ve got a stack of mixed-diameter tubes, manual swaps waste hours. Modular setups let you swap rotary chucks and laser heads in minutes—no teardown.

Quick-Swap Rotary Chuck Kits

- Downtime chasing the right chuck.

- Our “chuck kit” system means you grab the pre-built jaw set, twist it on, and you’re running.

- Real Case: A signage exporter in Europe cut their tube changeover from 45 min to 8 min, freeing up two shifts weekly.

Scanning Head Options for Thin & Thick Use

- Fine tubes need low-power focus; thick pipe wants high-power burst. You load the recipe into the HMI. No sweat. That’s exactly how our 5050 Fiber Laser Cutting Machine handles 1–8 mm brass tubes and still cranks out clean cuts on 50 mm steel—all in one rig.

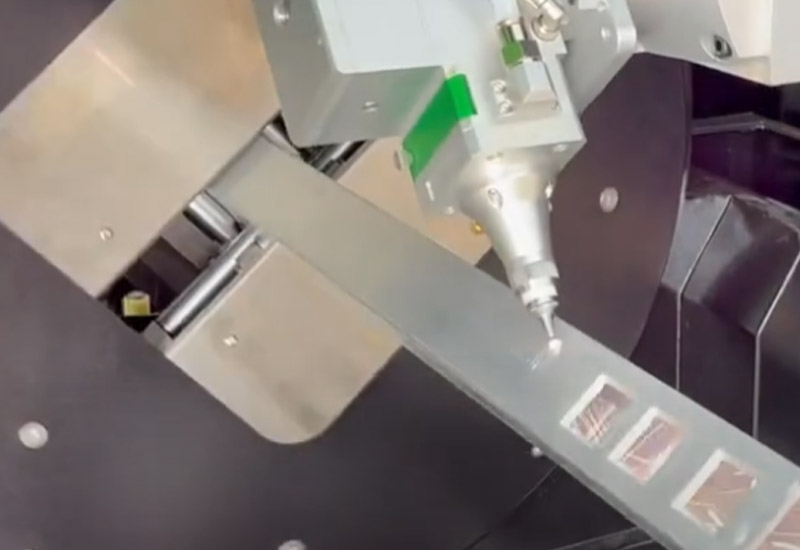

Advanced Beveling Cuts Burr-Free Edges on Metal Pipe Laser Cutting Machine

Complex fabricators insist on bevels for weld prep. No bevel, no peace of mind on site.

Groove Cutting & Chamfering by Fiber Laser Cutter

- Tech Note: Our bevel head throws a 0–45° chamfer by pivoting the RayTools module—zero mechanical jig.

- Benefit: You get ready-to-weld edges with <0.2 mm rebate error.

Burr-Free Finish with CleanTech

- We dial in “dross-blow” gas flow in the NC program so molten slag never sticks.

- An oil & gas pipe exporter in the UAE swapped old plasma bevelers for our Bevel Fiber Laser Cutting Machine. They cut post-weld grinding by 30%, boosting net export yield.

Sheet Metal & Pipe Fiber Laser Cutting Machine for One-Stop Flexibility

You don’t want separate rigs for sheets and tubes. Combo systems kill two birds.

| Model | Tube Ø Range | Sheet Size | Key Feature | Link |

|---|---|---|---|---|

| 5050 Fiber Laser Cutting Machine | 1–50 mm | 300 × 300 mm | Entry-level tube & sheet | 5050 Fiber Laser Cutting Machine |

| Automatic Loading Laser Tube Cutting Machine | 20–200 mm | N/A | Auto-feed & unloading | Auto Loading Tube Cutter |

| Bevel Fiber Laser Cutting Machine | 10–219 mm | N/A | Integrated bevel & chamfer | Bevel Fiber Laser Cutter |

| Laser Plate & Tube Combo Fiber Laser Cutting Machine | 6–219 mm | 1500 × 3000 mm | Dual-mode sheet & tube | Plate & Tube Combo Fiber Cutter |

| 3020 Fiber Laser Cutting Machine | 5–80 mm | 300 × 200 mm | Small-part precision | 3020 Small Fiber Laser Cutter |

Source: BOGONG Laser fiber portfolio.

High-Power Systems for Best Metal Pipe Laser Cutting Machine Performance

Heavy-wall pipe wants punch. That’s where 2 kW–8 kW setups shine.

- A construction steel exporter in Brazil needed 200 mm OD × 20 mm wall cuts. We rigged their 6000 W–40 kW series with a water-cool “super-pulse” for precise piercing.

- Sure, the capital tick is higher, but cycle time drops by 40% vs. oxy-fuel. You recoup in three shipments.

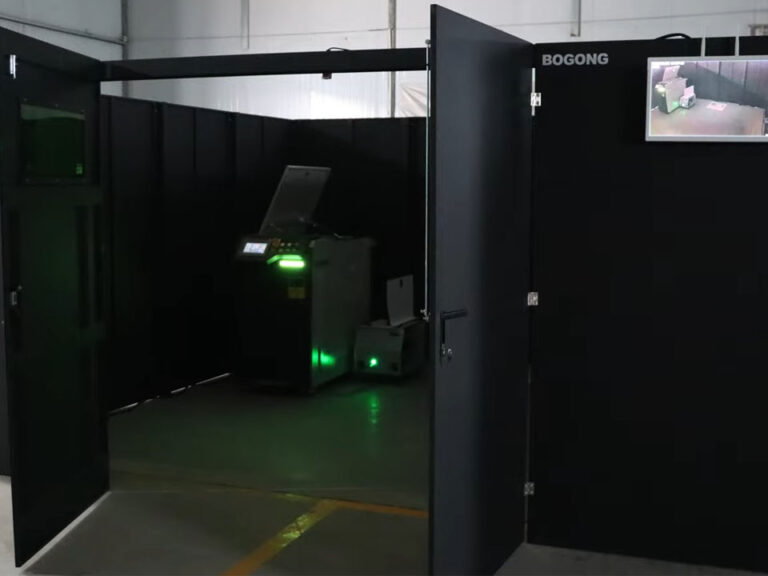

Global OEM & After-Sale Service

- As a top china metal pipe laser cutting machine maker, BOGONG Laser offers CE, FDA, ISO9001, SGS, France BV certs.

- Support: We ship spares kits with same-day courier to 160+ countries and run remote “delta-time” tuning sessions so you never stop.

Smart Controls & Industry-Focused Software for Wholesale Metal Pipe Laser Cutting Machine Buyers

It’s not just hardware. The brains matter.

- Fiber Laser Marking Machine Integration: You can add a marking head to the beam path—trace serial numbers, QR codes on pipe ends—right after cutting. No extra pass.

- Sheet Metal Laser Cutting Machine Mode: Flip a software switch and load DXF for flat parts. The g-code nester optimizes yield, slashing scrap by up to 12%.

- User Pain Point: Many exporters dread cryptic NC errors. We built a one-tap “recover run” feature—machine parks, you fix a minor jam, hit resume, and it auto-aligns.

Conclusion: Why You Should Care

Whether you’re moving small‐bore jewelry tubes or big steel trunks, customization isn’t optional—it’s critical for export efficiency. Flexible chucks, bevel modules, combo rigs, and smart software all combine to cut your cycle time, bump up yield, and dodge compliance delays. At BOGONG Laser, we specialize in tailoring each fiber laser cutting machine metal tube solution so you can hit every spec—on time, every time. Let’s team up and make your next shipment hassle-free.