-

Shunhua Road, Jinan City, Shandong

OEM ODM Laser Cleaning Machine for Ships

Discover how OEM/ODM laser cleaning machines for ships from BOGONG Laser cut maintenance time, boost efficiency, and ensure eco-friendly hull care.

Ships face brutal conditions at sea—barnacles, rust, old coatings. You need a cleaning solution that’s fast, green, and precise. Here’s why OEM/ODM laser cleaning machines from BOGONG Laser hit the sweet spot.

The complexity of ship environment cleaning

Diverse Cleaning Targets

Ship maintenance involves a wide range of surfaces and contaminants—rusted hulls, oil-stained engine rooms, barnacle-covered propellers, and corroded anchor chains. Each component varies in shape, material, and level of contamination, requiring different cleaning intensities and techniques. Standard machines struggle to adapt across such varied tasks.

Harsh Environmental Conditions

Marine settings are tough—high humidity, salt spray, and constant exposure to corrosive elements. Laser cleaning machines used on docks, shipyards, or onboard must endure these conditions without compromising performance. This calls for custom waterproofing, corrosion resistance, and robust enclosures.

Complex and Irregular Workspaces

Cleaning operations often take place in tight, angled, or elevated areas like ballast tanks, curved hulls, and vertical surfaces. Mobility, portability, and remote operation become essential. That’s where OEM/ODM laser cleaning solutions shine—they can be tailored with flexible designs, custom power supplies, and operator-friendly interfaces to handle real-world marine challenges.

Adapting to Complex Ship Structures

Hull geometry isn’t flat. Niches, weld seams, and hard‐to‐reach spots make traditional blasting a hassle. Laser beams flex to every nook.

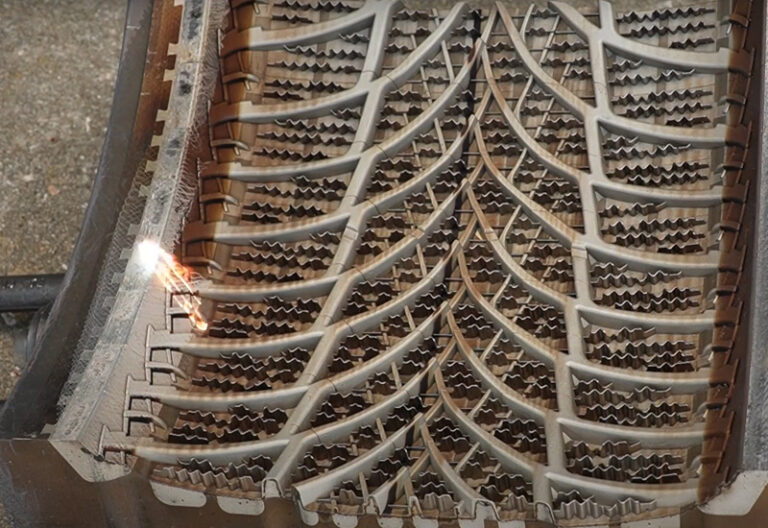

Taming Tough Fouling

From marine algae to barnacles, laser pulses vaporize buildup without chipping the steel. That’s a game-changer when biofouling hides in crevices.

Flexible Beam Delivery

Handheld wands, trolley setups, or robot mounts—choose what fits your shipyard. Go from tank decks to propeller shafts without swapping your workflow.

Want to see how BOGONG cleaning machine cleans ships? Click on the video below to watch.

Sustainable Cleaning Practices

Regulations tighten on chemical effluent and dust. Laser cleaning’s dry, chemical‑free process keeps you compliant—and protects marine life.

Chemical‑Free Workflow

You won’t rinse corrosive acids into harbor water or haul off tons of spent grit. That means lower disposal fees and no permit headaches.

Eco‑Friendly Footprint

Less waste, less cleanup, less fuss. Clients applaud a cleaner supply chain, and you avoid greenwashing accusations.

Non‑Contact Precision Cleaning

Worried about substrate damage? Laser cleaning targets oxides and paints, leaving base metal intact.

Protecting Hull Integrity

Coating layers vaporize at micron scale. No micro‑cracks, no undercuts, no stress risers. That keeps your hull plating strong and your weld seams sound.

Versatile Use Cases

From removing algae before ultrasonic inspections to pre‑welding surface prep, laser cleaning fits nearly every deck‑house scenario with no tool swap.

Custom OEM/ODM Solutions

You’ve got unique ship sizes, power setups, and integration needs. A one‑size‑fits‑all machine won’t cut it.

Factory‑Fit Options

BOGONG Laser’s modular design lets you pick pulse vs. CW operation, beam diameter, cooling method, even control interface. You get a tailor‑made tool, not a mass‑produced gadget.

Rapid Integration

Your Shipyard’s control tech and safety protocols stay intact. The machine talks to your PLC, aligns with your pre‑paint station, and snaps right into your lineup.

Reliable 24/7 Operations

Shipyards run round‑the‑clock. You need gear that won’t stall under heat or dust.

Water‑Cooled Stability

Forget overheating. A built‑in recirculating water system keeps the laser diode chill, so the beam stays consistent even in back‑to‑back shifts.

Built for Harsh Environments

Seal ratings, rugged casters, and easy‑clean filters mean you’re not patching up machines every month. It’s marine‑grade reliability.

Certifications Ensure Safety

CE, ISO9001, SGS and more—that’s the paperwork you need to prove you’ve met international rules. Don’t risk port fines or insurance hiccups.

With BOGONG Laser’s certified line, inspectors nod, lawyers smile, and you sail through audits.

Real Shipyard Success Stories

Table below shows how laser cleaning fits into daily shipyard life.

| Scenario | Pain Point | Benefit | Machine Model (link) |

|---|---|---|---|

| Barnacle and algae buildup | Hard‑to‑reach fouling causes drag | Fast prep, smooth hull regain | 1000W Pulse Laser Cleaning Machine |

| Old paint and rust undercuts | Chemical stripping eats time | Controlled substrate activation | 500W Pulse Laser Cleaning Machine |

| On‑board quick fixes | Limited space, no grit blasting won’t fit | Handheld mobility, zero mess | Trolley Case type Laser Cleaning Machine |

| Long production‑line cleaning | Continuous run burns out other techs | Stable beam, nonstop cleaning | CW Fiber Laser Cleaning Machine |

These wins cut rework, boost coating adhesion, and slash turnarounds. It’s kinda neat when you see a ship’s hull go from crusty to showroom‑fresh in minutes.

Get in Touch

Got questions?? Fill out our contact form and BOGONG Laser’s team will get back fast. Let’s make your next docking a breeze.