-

Shunhua Road, Jinan City, Shandong

OEM Fiber Laser Cutting Machine for Heavy Metal Plate

Upgrade your heavy metal cutting with an OEM fiber laser from BOGONG. Cut thicker plates faster with superior edge quality, reducing costs and boosting your shop's output.

1. Heavy Metal Plate Pain-Point Hook Introduction

Are you still struggling with thick metal plates? Slow cutting speeds, rough edges, and the endless grinding work after flame or plasma cutting are steadily eroding your profits and extending your delivery times. Every component that needs secondary processing adds to your labor costs and delays the entire project. In today’s market, where consumers require tighter tolerances and much shorter preparations, relying upon these traditional techniques resembles using a boring knife to carve a precision instrument– it’s not only ineffective but additionally unbelievably dangerous. It’s time to stop battling with obsolete innovation.

BOGONG Laser provides OEM fiber laser solutions specifically for manufacturers like you. We help you transform these pain points into tangible competitive advantages, making thick plate cutting precise, efficient, and economical.

2. Concept Popularization & Value Connection

So, what makes high-power fiber laser technology so magical?

Imagine traditional plasma or flame cutting is like drawing a line with a thick marker. The line is wide, the edges are blurry, and the ink (heat) bleeds deep into the paper (metal). This results in a wide kerf, a large amount of molten slag (dross), and a significant heat-affected zone (HAZ), forcing you to perform heavy grinding before a part can be welded.

Now, picture a fiber laser as an ultra-fine needle-point pen. Its line (the laser beam) is incredibly sharp and its energy is highly concentrated. It draws a clean, crisp line on the metal with almost no heat bleed.

What does this mean for your business?

- Zero-Waste Edges: A narrower kerf means less material is wasted.

- Cut-to-Weld Quality: Smooth, dross-free sides enable components to go straight to welding or assembly, completely getting rid of the lengthy and labor-intensive grinding procedure.

- Greater Yield: Precision reducing makes certain a perfect fit between parts, lowering rework and scrap caused by dimensional errors.

Ultimately, this technology converts the labor, time, and material costs previously spent on “correcting mistakes” directly into your profit.

3. Product Solution Bridge

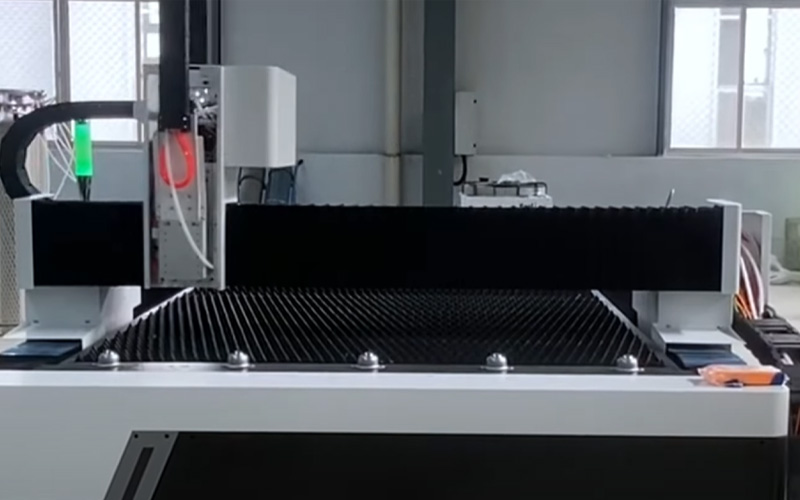

Theoretical advantages require powerful equipment to become a reality. BOGONG Laser integrates cutting-edge fiber laser technology into a robust machine body built for heavy-duty processing. Our equipment is the reliable tool you need to put the concepts above into practice.

Our 6000W-40KW High Power Fiber Laser Cutting Machine is the core of this solution. It’s not just equipped with a laser source powerful enough to pierce steel up to 80mm thick; more importantly, we’ve deeply optimized its structural design.

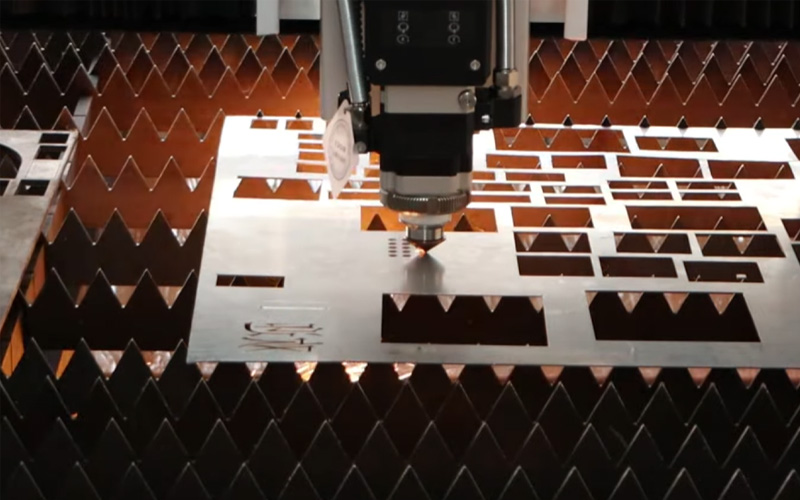

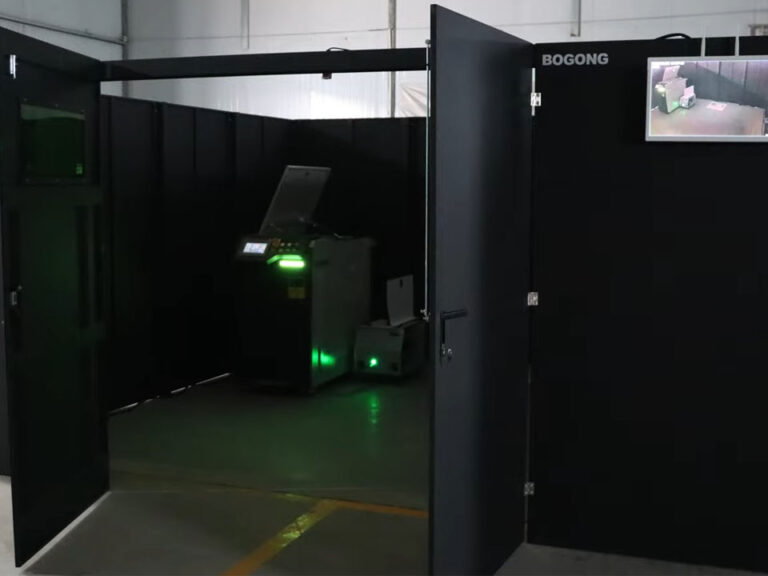

Watch the video below to see how our plate-welded machine body ensures ultimate cutting precision:

[/vc_column_text][cz_gap height=”30px”][vc_video link=”https://youtu.be/kv3tNysqvk0″ css=”” title=”See How This Laser Cutter Is Built Different From Others!”][cz_gap height=”30px”][vc_column_text css=””]

As the video explains, this heavy-duty plate-welded structure provides rock-solid stability, effectively suppressing vibrations that can occur when cutting heavy plates. Oversized bearing components ensure long-term operational accuracy and durability. It is this attention to detail that allows our machines to consistently transform powerful laser energy into the precise, clean cuts you require. We deliver more than just power; we provide a stable and reliable production platform.

4. Deep Dive into Core Benefits

By choosing BOGONG Laser equipment, you gain several core business advantages:

Shatter Thickness Barriers, Expand Your Business

In the past, getting an order for plates thicker than 30mm might have implied outsourcing the task or turning it down. Now, you can confidently bid on these high-profit, durable tasks. Our high-power equipments easily handle thicknesses that were as soon as difficult, whether it’s for heavy machinery chassis, structural steel nodes, or ship hull plates. You can finish all of it in your own workshop, offering you full control over top quality, cost, and distribution schedules.

Multiply Your Processing Speed, Accelerate Cash Flow

In manufacturing, time is money. Our equipment will redefine “speed” for you. When reducing 20mm carbon steel, for example, a 20kW laser is 50%-320% faster than a standard 12kW maker. This implies a job that utilized to take a complete day can currently be finished in just half a day or much less. This jump in performance allows you to refine more orders in the very same amount of time, dramatically shortening your order-to-cash cycle.

| Laser Power (W) | Max Cutting Thickness – Carbon Steel (mm) | Max Cutting Thickness – Stainless Steel (mm) | Max Cutting Thickness – Aluminum (mm) |

| 6,000 | ~25 | ~25 | ~20 |

| 12,000 | ~40 | ~30 | ~30 |

| 20,000 | ~70 | ~60 | ~50 |

| 30,000 | ~80 | ~70 | ~60 |

Deliver “Grind-Free” Quality, Slash Hidden Costs

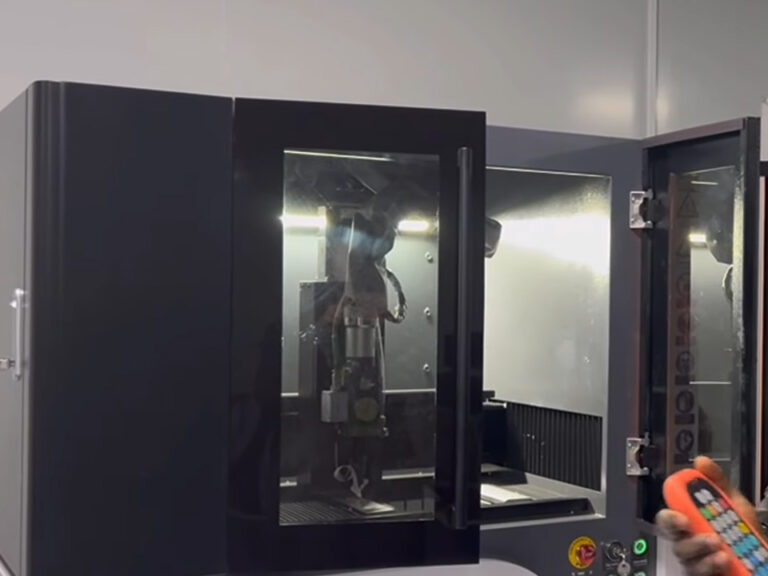

The grinding process, a major headache for workers, can now be largely eliminated. Thanks to a minimal heat-affected zone and advanced process controls, our machines produce exceptionally smooth, slag-free cuts. This “cut-to-weld” quality saves you significant costs on labor and consumables (like grinding wheels) and prevents errors that can be introduced during secondary processing. For weld preparations requiring V, X, or Y-grooves, our Bevel Fiber Laser Cutting Machine can even create them in a single pass, boosting efficiency even further.

5. Scenario-Based Story (The Lifecycle of a Heavy Structural Component)

9:00 AM – Drawing Received

An urgent order arrives from an engineering machinery client: a batch of 40mm thick Q345B steel support arms for an excavator chassis. The edges must be beveled for robotic welding.

9:30 AM – Program Preparation

A technician imports the drawing into the BOGONG Laser bevel cutting machine’s control system. The software program automatically acknowledges the contours and, making use of predetermined parameters from the material library, swiftly produces a reducing course that includes the 45-degree bevel. The whole procedure takes less than 10 minutes.

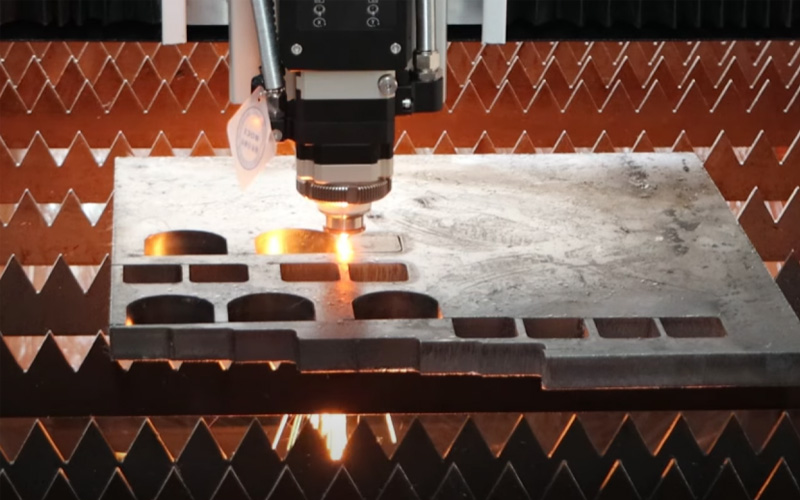

10:00 AM – Cutting Begins

An operator hoists a massive steel plate onto the cutting bed. With the press of a button, the powerful laser beam instantly pierces the thick plate. The cutting head moves at high speed while automatically adjusting its angle, precisely cutting the required profile and bevel. There is no harsh noise or excessive smoke, only an efficient and smooth cutting process.

12:00 PM – Cutting Complete

All the support arm parts on the plate have been cut. The operator inspects one of the parts: the edge is as smooth as a mirror, the bevel angle is precise, and a caliper measurement of the diagonals shows a tolerance of less than 0.2mm. No secondary processing is needed.

1:30 PM – Transferred to Welding

The “grind-free” parts are sent directly to the welding station. Because the bevels are uniform and consistent, the parts fit together perfectly, allowing the robotic welding to proceed smoothly and ensuring excellent weld quality and strength.

The lifecycle of this project was shortened by an entire workday compared to the old method of plasma cutting followed by manual grinding.

6. Answering Concerns & Future Planning

Concern 1: “Isn’t the initial investment for a high-power fiber laser much higher than plasma?”

Yes, the initial capital investment is higher, but the key metric to consider is the Total Cost of Ownership (TCO). A fiber laser has virtually no consumables (unlike the electrodes and nozzles for plasma), boasts higher electrical efficiency, and eliminates the need for post-cut grinding labor. When you factor in the savings on operational costs and the increased revenue from higher throughput, the initial investment difference is often recovered in a short period (e.g., 12-24 months), after which it begins to generate significantly higher profits.

Concern 2: “How difficult is it to integrate such an advanced machine into my existing workflow?”

It’s not difficult at all. We provide a complete OEM/ODM solution. The BOGONG Laser team offers comprehensive on-site installation, commissioning, and operator training. Our machine control systems feature an intuitive interface and are compatible with all major CAD/CAM software, allowing your technicians to get up to speed quickly. We are committed to making technology work for you, not become a burden.

Future Planning: An Investment in Tomorrow

Laser technology continues to advance rapidly, with trends moving towards even higher power and smarter automation. Investing in an advanced BOGONG Laser platform today means you are not only solving your current production bottlenecks but also preparing for the future of manufacturing. Your equipment will be able to adapt to more demanding processing needs through software updates and modular expansions, ensuring the long-term value and competitiveness of your investment.

7. Brand Trust Building: Why Partner with BOGONG Laser?

When choosing a partner, machine performance is the foundation, but the company’s strength and reputation are the guarantee. BOGONG Laser has established an outstanding reputation in the global laser industry.

- The Choice of Global Clients: We serve a global B2B market, with customers in sectors ranging from metal fabrication and automotive to signage, electronics, and crafts.

- A Worldwide Sales Network: Our products have been sold in over 160 countries and regions, serving more than 9,000 clients and successfully completing over 425 major projects. This vast portfolio demonstrates widespread market trust.

- Authoritative International Certifications: Our products and operational systems are certified by numerous international authorities, including CE, ISO9001, SGS, and FDA, as well as BV in France. These certifications are your assurance of receiving safe, reliable, and high-quality equipment.

- Comprehensive Product Line: In addition to our Fiber Laser Metal Cutter, our product matrix includes laser cleaning, welding, marking, and engraving machines, enabling us to provide you with one-stop laser application solutions.

8. Conclusion & Call to Action

Stop letting outdated equipment slow down your progress. It’s time to embrace a more efficient, precise, and cost-effective method of production. BOGONG Laser‘s OEM fiber laser cutting machines are the powerful tools you need to stand out in a competitive market.

Contact our technical specialists today to discuss the specific challenges you face with thick plate cutting. Let us tailor a solution that will tangibly boost your profitability.