-

Shunhua Road, Jinan City, Shandong

ODM Handheld Laser Welder for Small Workshops

Boost your small workshop’s productivity with a Handheld Laser Welder. Fast, clean, and easy to use—perfect for precise metal welding and increased profits.

Tired of the old weld-and-grind routine? If you run a small metalworking shop, you know the drill. Finding a welder who can lay down a perfect TIG bead is tough, and paying them what they’re worth is even tougher. Meanwhile, MIG welding is faster, but the cleanup—all that spatter and grinding—steals your time and profit. You’re stuck in a cycle of compromises.

What if you could ditch that cycle for good?

That’s not just a sales pitch; it’s the reality that thousands of small workshops are discovering with handheld laser welding. This isn’t the giant, million-dollar robotic setup you see in car factories. This is a compact, powerful tool designed specifically for workshops like yours. And at BOGONG Laser, we’ve perfected the Handheld Laser Welder to be your partner in growth, not just another machine on the floor.

Through our ODM (Original Design Manufacturer) program, you don’t just buy a tool; you build your own brand. You get a machine customized for your business, backed by our expertise as a global leader with clients in over 160 countries. Let’s break down how this technology isn’t just a replacement for your old welder—it’s a complete upgrade for your entire business.

Why Handheld Laser Welders are a Perfect Fit for Your Workshop

Switching to a new technology can feel like a big leap, but the benefits of handheld laser welding aren’t just marginal gains. They represent a fundamental shift in how you work, saving you time, money, and a lot of headaches.

Forget the Steep Learning Curve

Let’s be honest, the biggest bottleneck in most shops is skilled labor. You can’t just hire someone off the street to TIG weld. It takes months, even years, of practice to become proficient.

A Laser Welding Machine changes that. We’ve seen it time and again: a new operator, with zero welding experience, can be trained and laying down strong, beautiful welds in a couple of hours. The interface is simple. You select the material and thickness, and our pre-programmed settings do most of the heavy lifting.

This solves the “skilled labor” problem overnight. You no longer have to turn down jobs because your one experienced welder is swamped. Your existing team can learn quickly, making your entire operation more flexible and resilient.

Get More Done, Faster

In a small workshop, time is everything. Handheld laser welding is anywhere from 2 to 10 times faster than traditional methods. Think about that. A stainless steel handrail that took an hour to TIG weld can now be finished in under 15 minutes. A series of tack welds for a large assembly? Done in seconds.

This isn’t just about working faster; it’s about increasing your capacity. You can take on more jobs without needing more space or more people. The speed of the Laser Welder directly translates to higher throughput and bigger revenue. It’s the simplest path to scaling your operations.

Flawless Welds, Less Cleanup

What’s the first thing you do after a traditional weld? You grab an angle grinder. All that spatter, discoloration, and unevenness needs to be smoothed out before the piece can move to the next stage. This post-processing work is pure, unpaid labor.

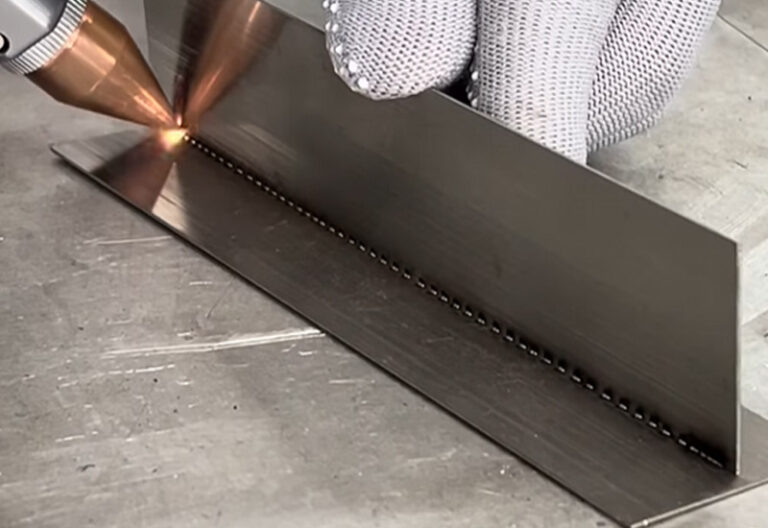

Laser welding practically eliminates it. The heat-affected zone (HAZ) is extremely tiny, which implies marginal bending, even on thin sheets of steel. The weld bead is tidy, smooth, and consistent. In most cases, the part is ready for paint, powder coating, or delivery right off the welding table. Just imagine how many hours of grinding you could save in a week.

Our Handheld Laser Welding Machine is engineered for exactly this result: a perfect weld, every time, with almost no cleanup required.

The BOGONG Laser Advantage

We don’t just sell equipment; we provide complete solutions. Our latest innovation is a perfect example of how we listen to the needs of small workshops.

Check out our new air cooling laser welder.

As you can see, we removed the large, hefty water chiller. This device is cooled down by air, making it exceptionally mobile and compact. You can easily move it around the shop or even take it to a job site. It’s the ultimate in flexibility, designed for the dynamic environment of a custom fabrication shop.

One Machine, Multiple Jobs: The Power of 3-in-1

For a tiny workshop, every square foot of floor area is priceless. You can not afford to have single-purpose equipments resting idle. That’s why our multi-function welders are so popular.

With a simple swap of the nozzle and a change in the settings, your Laser Welder can transform.

- Welder: For creating strong, clean joints.

- Cutter: For making precise cuts in thin metal sheets.

- Cleaner: For stripping rust, paint, or oils before welding or after.

This isn’t a gimmick. It’s a practical, cost-effective solution. You get the capabilities of three different machines in one compact footprint. Our 3 in 1 Handheld Laser Welder is one of the smartest investments a growing workshop can make, delivering incredible value and versatility.

Built for Safety, Built for You

We comprehend that the word “laser” can appear intimidating. Yet safety and security is at the core of our style. Our handheld welders are equipped with a multi-stage safety interlock system. The laser will only fire when the copper nozzle is in direct contact with a metal surface. If it loses contact, the laser shuts off instantly. This prevents any accidental exposure, protecting you and your team.

Real-World Scenarios for Laser Welding

The best way to understand the impact of this technology is to see how it’s used in the real world. This isn’t just for high-tech aerospace parts; it’s for the everyday jobs that small workshops tackle.

- Stainless Steel Kitchens & Furniture: A custom shop that builds commercial kitchen equipment uses a handheld laser welder to join thin stainless steel sheets for countertops and sinks. The lack of warping and the smooth finish reduced their finishing time by over 70%, allowing them to double their output.

- Automotive Repair & Customization: An auto body shop specializing in classic car restoration uses our machine for patch panels. The minimal heat input means they can weld in a new piece of sheet metal without distorting the surrounding panel, saving hours of bodywork.

- Doors, Windows, and Architectural Metal: A fabricator of custom steel-framed windows and doors relies on laser welding for the sharp, clean corners their high-end clients demand. The process is so clean that the frames can go directly to powder coating without any grinding.

- Metal Art & Signage: An artist creating intricate metal sculptures found that their TIG welder couldn’t handle the delicate joints without melting the material. With a BOGONG Laser Welder, they can now create complex, detailed pieces that were previously impossible.

These are just a few examples. From tool and mold repair to electronics and jewelry, the uses are nearly endless. You can explore more Laser Welding Machine Applications on our site to see how it fits your specific line of work.

The ODM Partnership: Build Your Brand with BOGONG Laser

Here’s where it gets really interesting for you as a business owner. Buying a machine is one thing. Building a brand is another.

Our ODM program allows you to do just that. We manufacture the machine, and you sell it under your own brand name. We can customize the machine’s color and add your logo, giving you a unique product to market in your region. You get a world-class, CE/FDA/ISO9001 certified machine without the massive R&D and manufacturing costs.

You’re not just a customer; you’re a partner. You leverage our decade of experience and our presence in over 160 countries. With over 9,000 satisfied clients, we have a proven track record of reliability and performance. This is your chance to stand out from the competition by offering a technologically advanced solution under a brand that your customers trust—yours.

The Numbers Don’t Lie: Laser vs. Traditional Welding

Still on the fence? Let’s look at the hard data. We’ve compiled a comparison based on industry standards and internal testing to show why a BOGONG Laser Welder is a smarter financial choice.

| Feature | Handheld Laser Welder (BOGONG) | Traditional TIG Welding | Traditional MIG Welding |

| Speed | 2-10x Faster | Slow, meticulous | Moderate speed |

| Skill Level Required | Low (Hours of training) | High (Years of experience) | Medium (Weeks of practice) |

| Post-Weld Cleanup | Minimal to None | Often requires grinding/polishing | Heavy spatter, requires grinding |

| Heat Affected Zone (HAZ) | Extremely Small (minimal warping) | Small (but can warp thin metal) | Large (high risk of warping) |

| Material Versatility | High (Steel, Aluminum, Brass, etc.) | High (but requires different gas/rods) | Good (mainly for steel) |

| Consumables | Very Low (Mainly electricity) | Tungsten electrodes, filler rods, gas | Contact tips, wire spools, gas |

| Best For | Precision, speed, and aesthetics | High-quality, precise welds on any material | Speed on thicker steel sections |

| Our Recommended Model | Handheld Laser Welding Machine | N/A | N/A |

Choosing Your First Handheld Laser Welder

Ready to make the switch? The most important factor to consider is laser power.

- 1000W-1500W: Perfect for thin sheet metal (up to 3mm), ideal for signage, kitchenware, and intricate work.

- 2000W-3000W: The all-around workhorse. This gives you the power to handle thicker materials (up to 6-8mm) while still having the finesse for delicate jobs.

At BOGONG Laser, we offer a full range of machines to fit your needs and budget. We’re here to help you figure out the perfect configuration for your workshop. You can browse our complete collection of Laser Welding Machines to see all the options.

The bottom line is this: a handheld laser welder is no longer a luxury. It’s a foundational tool for any modern fabrication shop that wants to stay competitive. It allows you to work faster, produce higher quality products, and lower your reliance on a shrinking pool of highly skilled labor.

Stop grinding away your profits. It’s time to upgrade your workshop and your business model.

Ready to see the difference for yourself? Contact the BOGONG Laser team today for a consultation or a live demo.