-

Shunhua Road, Jinan City, Shandong

ODM Fiber Laser Welder for Shipbuilding for Middle East

Upgrade your shipyard with a custom Fiber Laser Welder. Weld steel 3-5x faster using a Handheld Laser Welder for flawless seams and higher productivity.

Welding in a shipyard is tough work. You’re dealing with massive steel plates, long weld seams, and tight deadlines. In the Middle East, you’re also battling the heat. For decades, traditional welding methods like MIG and TIG have been the go-to, but they come with headaches. They’re slow, they warp the metal, and finding enough highly skilled welders is a constant challenge.

What if you could leave those problems behind?

What if you could weld steel plates three to five times faster, with perfect, clean seams that need almost no grinding? That’s not a fantasy. That’s what a Fiber Laser Welder brings to your shipyard. At BOGONG Laser, we don’t just sell you a machine; we partner with you to build the exact solution you need. As an Original Design Manufacturer (ODM), we tailor our technology to solve your specific problems.

Why Traditional Welding Is Slowing You Down

If you run a shipyard, you know the daily grind. Your team spends hours laying down a single long seam. The intense heat from the arc causes the steel plates to warp—what the industry calls heat distortion. This means more time and money spent on post-weld straightening and grinding to get a smooth finish. It’s a bottleneck.

And let’s talk about labor. A great TIG welder is an artist, but they are expensive and hard to find. Your quality depends entirely on their skill and consistency, which can be a huge variable in a large-scale project. These are the pain points that eat into your profits and delay your projects.

Key Advantages of a Fiber Laser Welder in Shipbuilding

Switching to a Laser Welding Machine isn’t just a small step up; it’s a massive leap forward in efficiency and quality. Here’s how it directly benefits shipbuilding operations in the Middle East.

Boost Speed and Cut Costs

Imagine turning hours of welding into minutes. A Handheld Laser Welder moves as fast as you can guide it, laying down perfect seams at incredible speeds. For the long, continuous welds on a ship’s hull, this completely changes the game.

But the speed is just the start. You also save money everywhere else:

- No More Grinding: The weld is so clean and smooth, you can practically eliminate post-weld grinding. That’s a huge saving in labor and abrasives.

- Fewer Consumables: Unlike MIG welding, you don’t need wire spools, tips, and other consumables. Just a simple shielding gas.

- Lower Power Bills: Laser welders are highly energy-efficient, translating to lower operational costs over time.

As an ODM partner, BOGONG Laser ensures you get a machine built for your needs. You’re not paying for features you won’t use. We focus on what gives you the best return on investment. For versatile and powerful solutions, our general Handheld Laser Welder is a fantastic starting point for any shipyard.

Get Perfect, Stronger Welds Every Time

In shipbuilding, weld quality is non-negotiable. It’s about safety and durability. A fiber laser welder creates a deep, narrow weld with a very small heat-affected zone (HAZ).

What does this mean for you?

- Less Distortion: The minimal heat input means your steel plates stay flat. No more warping or buckling.

- Incredible Strength: The deep penetration creates a weld that is often stronger than the parent metal itself.

- Perfect for Automation: The process is so precise and repeatable, it’s perfect for integrating into automated gantry systems for welding massive panels.

Built Tough for Middle East Operations

A workshop in the Middle East can be a demanding environment. High ambient temperatures can cause other equipment to overheat and fail. We get it.

That’s why our machines are built for high-intensity, 24/7 work. Our laser welders use robust cooling systems to ensure consistent performance, even when the temperature outside is soaring. For workshops where water cooling might be a challenge, we’ve developed powerful air-cooled models. Our Air-Cooling Handheld Laser Welding Machine is specifically designed for maximum uptime and reliability in any environment.

So Easy, Your Whole Team Can Use It

You no longer have to rely solely on a few master welders. A handheld laser welder is incredibly easy to learn. The interface is simple, and the “point-and-shoot” process is intuitive. After a few hours of training, a general laborer can produce perfect, consistent welds.

This solves the skilled labor shortage. You can empower more of your team to perform high-quality welding, making your entire operation more flexible and resilient. For a machine that combines welding, cleaning, and cutting in one easy-to-use package, check out our 3 in 1 Handheld Laser Welder.

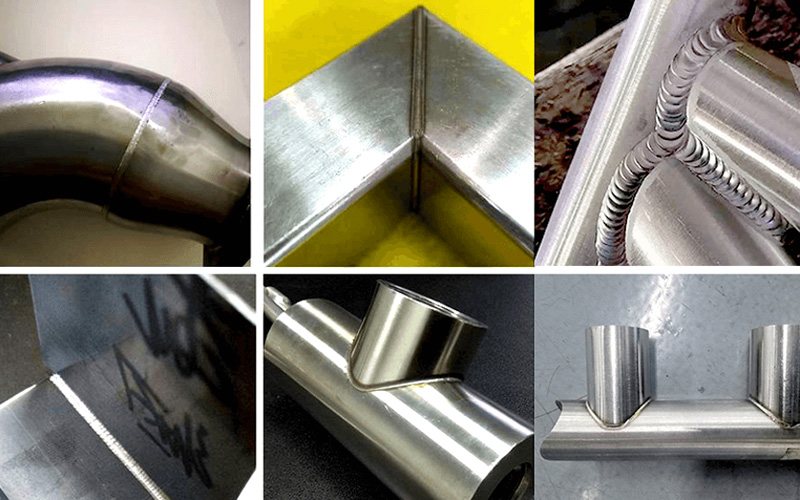

Handle Any Job, from Hulls to Handrails

Shipbuilding isn’t just about welding massive steel plates. It’s also about intricate pipework, installing fixtures, and working with different metals like aluminum and stainless steel. The flexibility of a Laser Welder is unmatched. With a long, flexible fiber optic cable (often 10-15 meters), your operator can easily move around large components.

Our systems can be quickly adjusted to handle different materials and thicknesses. And with features like a wobble head, the laser can even compensate for small gaps or imperfect fit-ups, which is a common reality in large-scale fabrication. This means you can use the same machine for hull plates, HVAC ducts, railings, and more.

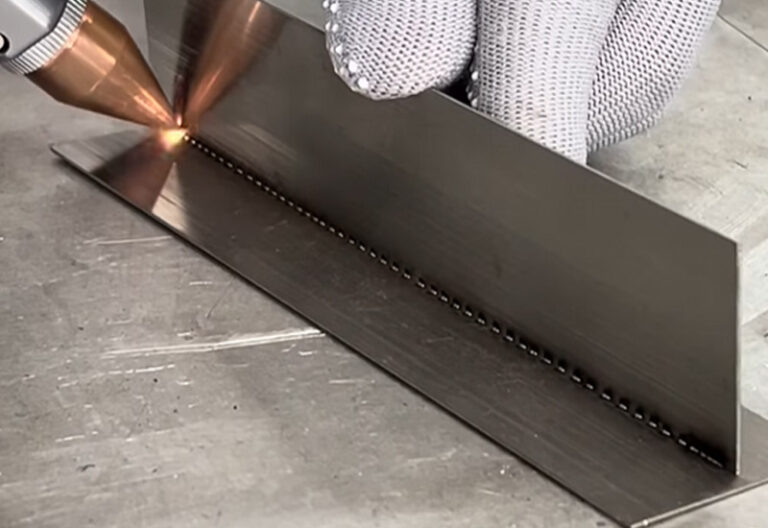

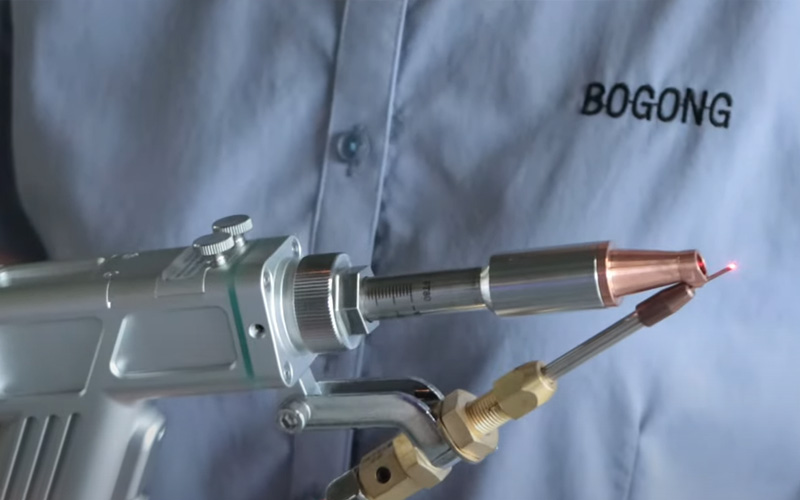

Seeing is Believing: Laser Welder Heads in Action

It’s one thing to read about it, but another to see it. The “business end” of the machine is the welding head. Its design determines the ergonomics, features, and quality of the weld. This video shows several different types of handheld fiber laser welding heads so you can see the technology up close.

Comparison Table: Laser Welding vs. Traditional Methods

Still not convinced? Let’s put it in black and white. Here’s a simple breakdown of how a Fiber Laser Welder stacks up against the old methods.

| Feature | Fiber Laser Welding (BOGONG Laser) | Traditional Welding (MIG/TIG) |

| Speed | 3-5x Faster | Slow, manual process |

| Weld Quality | Smooth, clean, deep penetration | Dependent on operator skill; often requires rework |

| Distortion | Minimal to none | High risk of heat distortion and warping |

| Post-Weld Work | Little to no grinding needed | Extensive grinding and finishing required |

| Skill Level | Easy to learn; basic training | Requires highly skilled, certified welders |

| Flexibility | Welds various metals & thicknesses | Often requires different machines or setups |

| Consumables | Only shielding gas & protective lenses | Wires, tips, electrodes, gas |

BOGONG Laser: Your ODM Partner for Shipbuilding

For over a decade, BOGONG Laser has been a global leader in CNC laser technology. We’re not just a seller; we’re a manufacturer with CE, SGS, and ISO9001 certifications. Our machines are trusted by over 9,000 clients in 160 countries for one simple reason: they work.

As your ODM partner, we work with you to understand the unique challenges of your shipyard.

- Do you need a longer fiber cable to reach difficult areas? We can do that.

- Need a specific power level for a special type of steel? We’ll build it.

- Need to integrate the laser into an automated gantry? We’ll help you design the system.

We provide a direct-from-factory solution, cutting out the middleman and giving you the best possible value. Explore our full range of Laser Welding Machine solutions or browse our specific fiber laser welder category to see what’s possible.

The future of shipbuilding is faster, cleaner, and more efficient. It’s time to stop grinding and start winning more contracts.

Contact BOGONG Laser today to discuss a custom ODM solution for your shipyard.

Laser Welding Machine for Jewelr