-

Shunhua Road, Jinan City, Shandong

How 1000W Pulse Laser Cleaning Machine Rust Removal the Metal

1000W Pulse Laser Cleaning Machine eliminates stubborn rust and coatings safely, cuts prep time, avoids chemicals, streamlines metal cleaning workflow.

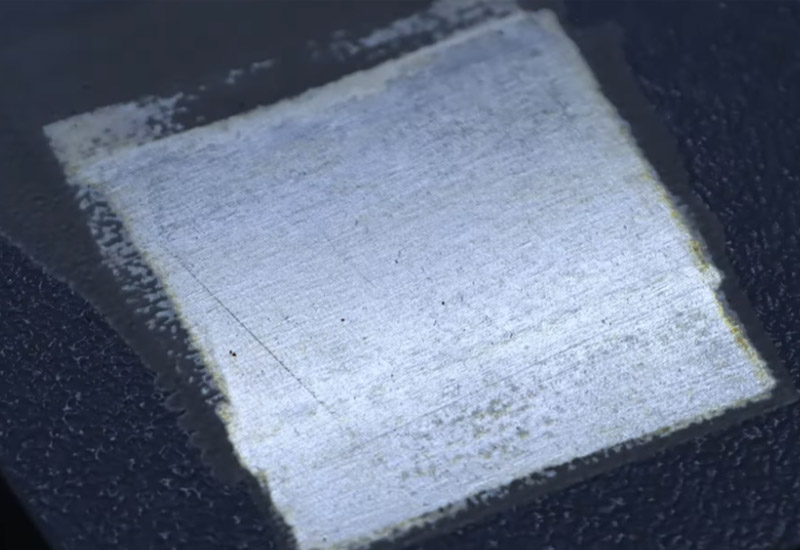

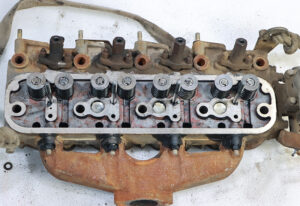

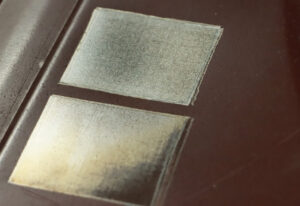

Imagine you’ve got an old steel mold caked in rust and oxide scale. You fire up a 1000W pulse laser cleaning machine, and within minutes, the metal substrate gleams like new—no heat warping, no messy grit.

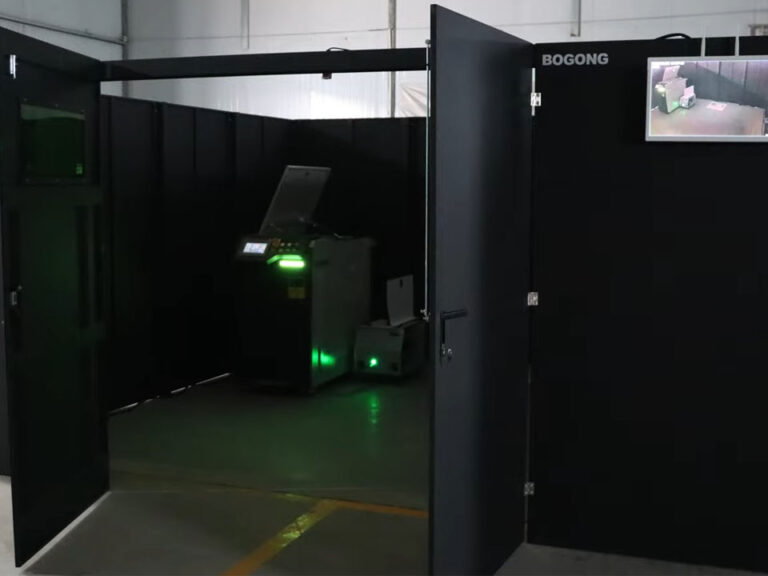

That’s the kind of magic BOGONG Laser delivers with our 1000W Pulse Laser Cleaning Machine . Below, we break down the top ten clinchers that make this tech a must-have for metal-working pros like you.

Rapid and Precise Rust Removal

You want rust off fast, right? A 1000W pulse laser cleaning machine uses high-peak micro-pulses to vaporize oxide scale without overheating the substrate. That means no warpage, no micro-fissure, just clean metal.

A shipyard swapped out abrasive blasting for a BOGONG 1000W unit on turbine blades. They cut prep time by 60% and avoided the common thin-metal warpage you see with sand.

Versatile Cleaning Scenarios

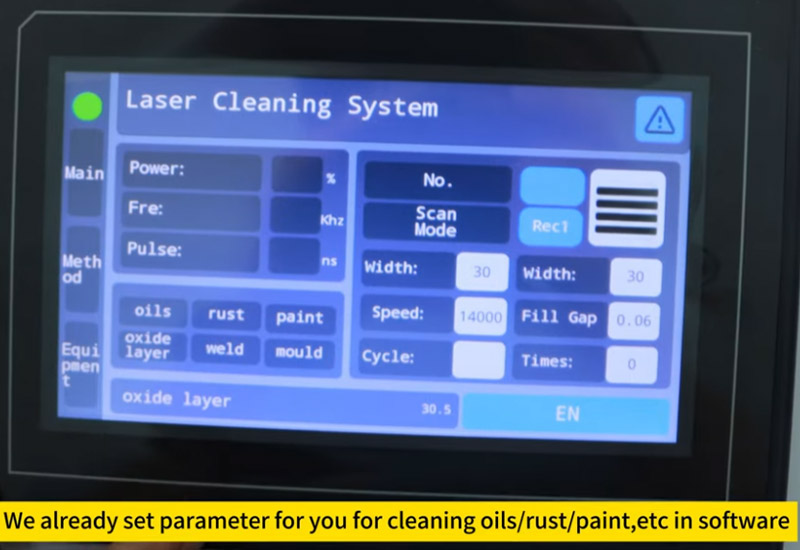

Don’t box yourself into “just rust.” Pulse laser cleaning handles a bunch of fouling: oxide scale, paint peel, oil residue, even old adhesive. That versatility makes it supremely useful across industries—from mold repair in automotive shops to delicate heritage restoration.

- Mold shops strip hardened polymer mock-ups without substrate damage.

- Aircraft MRO removes burnt coatings on landing-gear parts.

- Jewelry makers clear tarnish and plating mishaps.

Dive deeper into our lineup:

Short-Pulse Heat Control

Here’s where “pulse” shines. Ultra-short bursts pack tons of energy in microseconds. You vaporize rust or coating, and the metal beneath barely heats up. That tight heat-affected zone (HAZ) gives you fine-tuned control, so you won’t blow out thin edges or warp precision parts.

Real talk: A precision mold shop used our 1000W cleaner on a thin-walled die. They tweaked pulse width to under 200 ns and got zero warping—something sandblasting simply couldn’t match.

Eco-Friendly Process

You don’t want chemical waste or grit slurry clogging your day—and the regs. Laser rust cleaning machines produce zero hazardous waste, no acid baths, no water runoff. That’s a green tick for your site, and it lets you call out “no chemicals” in your bids. It’s compliance-ready and it boosts your green creds with clients.

Low Maintenance & Long Life

The heart of a pulse laser cleaner is its beam source. With 50,000–100,000 hours of life, you simply plug in power and air, swap the occasional filter, and you’re good. No oil changes, no abrasive stock to reorder, no batch of acid to dispose. That ease-of-keeping frees you to focus on production, not maintenance.

Direct Post-Clean Workflow

Once you’ve blasted off rust and residue, the cleaned metal is ready for the next step—no secondary treatments. You can weld, paint, or re-coat right away. That seamless flow slashes process steps and knock-on downtime.

Example: A metal fab shop used the 1000W unit to prep parts before robotic welding. They avoided a separate grinding station and cut cycle time by 25%.

Flexible Service Models

Whether you own the machine or hire it as a service, you can choose area-based or time-based billing. That means you only pay for the square meters you clean or the hours you run. If you’ve got a small on-site job, time-charge makes sense. For big cleaning runs, area-rate is the way to go.

Check out our service options on the Trolley Case type Laser Cleaning Machine page.

Non-Contact, No Secondary Pollution

Forget sand, grit, or soda blasting. Laser cleaning is fully non-contact—you don’t touch the metal with an abrasive. That means no secondary dust or slurry, and no extra clean-up. You won’t be breathing dust or deploying hoods and vacs. It’s a bare-metal process that leaves your floor and lungs happy.

Advanced Heads & Modes

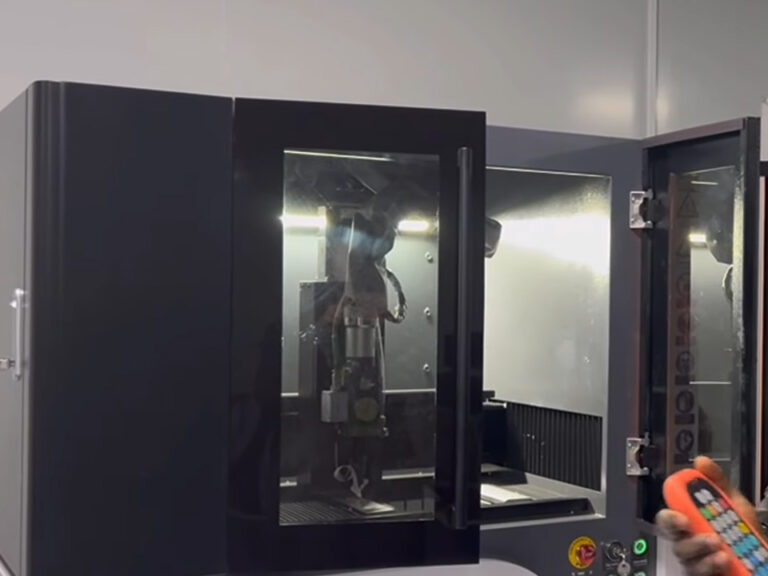

Modern pulse laser cleaners let you swap between single-mode spot and multi-mode scanning beams. Some units sport dual-scan heads for wide coverage or pinpoint detail. That tech lets you tackle large castings one minute and micro-etch the next.

A mold maker used the dual-scan head to strip a 1 m² cast plate—then switched to the fine-spot head to clean detailed cavities, all in one setup.

Watch Before You Buy

Need to see it in action? Check our video:

Looking for a reliable laser machine manufacturer? See why our 1000W Pulse Laser Cleaner rules the roost.

Laser Cleaning Machine for Application

Our laser cleaning machine is used in many scenarios and can usually solve many problems for you. Multi-Scenario Laser Cleaning Solutions:

Laser Cleaning Machine for Cars

Laser Cleaning Machine for Metal

Laser Cleaning Machine for Paint

Laser Cleaning Machine for Wood

Conclusion

You’ve seen how a 1000W pulse laser cleaning machine rips rust off metal fast, handles all sorts of fouling, and drops your total cost of ownership. It’s green, non-contact, low-maintenance, and hooks straight into your welding or coating line. At BOGONG Laser®, we’re all about real cases, real data, and real ROI. If you’re ready to ditch the sand and acid, hit us up—we’ve got global B2B creds in metalwork, automotive, signage, and more.