-

Shunhua Road, Jinan City, Shandong

Handheld Laser Welding Machine for Stainless Handrails

Handheld Laser Welding Machine for stainless handrails—faster cycles, low heat, clean finish. Tips, tables, and BOGONG LASER picks for real shop results.

A Handheld Laser Welding Machine for stainless handrails is a portable tool that utilizes a concentrated, high-energy laser beam of light to thaw and join stainless steel parts, developing a strong, smooth weld with high accuracy and minimal heat-affected areas.

Why a handheld laser makes sense on handrails

Thin-wall 304/316 rails hate heat. They warp, they color, and someone spends Saturday fixing it. A handheld laser focuses energy in a tight spot, so you move faster with smaller heat-affected zones. Translation: cleaner beads, less rework, nicer grain finish after a quick pass with the belts.

What changes on the shop floor

Faster travel on lap and fillet joints; still controlled.

Lower heat means less straightening and fewer “banana” rails.

You can run wire when the fit-up isn’t perfect.

With wobble, you widen the bead a bit without dumping heat.

Proper gas coverage gives you silver/stra w colors instead of dark heat tint.

Core claims you can actually use

Speed and cycle time

Most shops see multiple-fold gains over TIG on typical stair/guard rail joints. Not talking fantasy numbers; just the reality of narrow energy input and consistent arcs. The baton pass to finishing goes quicker because there’s less spatter and almost no undercut to dress.

Heat input and finish quality

Lower heat input = smaller HAZ = less distortion. That’s why rails come off the jig straighter and the brushed finish returns fast. If you’re selling mirror polish or tight hairline grain, this matters a lot.

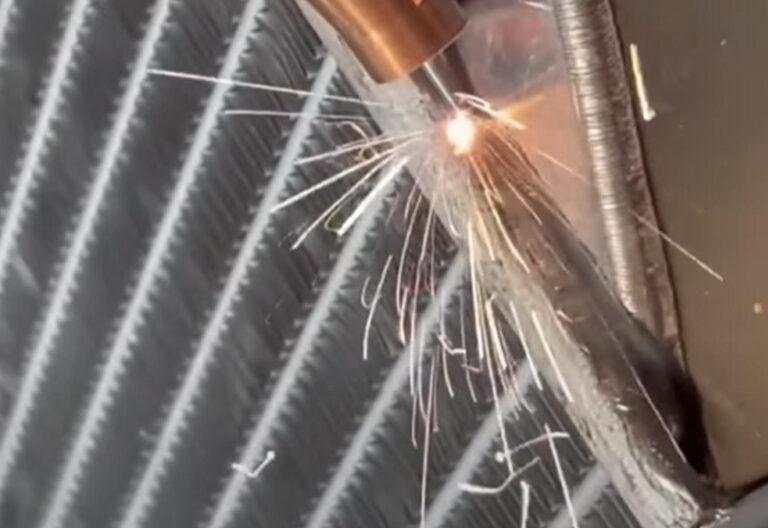

Here is a video showing how BOGONG works with a handheld laser welder.

Fit-up, wire, wobble

Reality check: field fit-up isn’t always pretty. If the gap is tight, you can autogenous (no wire). If the gap opens up, feed wire and add wobble to bridge it. This combo stabilizes wetting on corners and saddle joints at posts.

Gas shielding and “no more rainbow”

Stainless hates oxygen at heat. Keep a solid argon flow, keep the nozzle close, and use a trailing shield on long seams. You’ll see less blue/brown heat tint, which means faster back-to-metal and better corrosion behavior after passivation.

Snapshot table: claims → what it means for handrails

| Claim | What it means in stainless handrails | Shop-floor move | Notes that matter |

|---|---|---|---|

| Faster than TIG on thin-wall tubing | Shorter cycle time per joint, fewer bottlenecks | Use steady travel, short stick-out, keep the spot on the seam | You don’t chase the puddle; let the laser lead |

| Lower heat input | Less distortion, rails stay straight | Clamp smart, avoid over-tacking, don’t linger | Small HAZ = easy finishing |

| Wobble control | Wider bead without flooding heat | Turn wobble on for corner caps, post-to-rail saddles | Smooths out appearance when the gap ain’t perfect |

| Wire assist | Bridges gaps, boosts reinforcement | Pick wire that matches base metal, keep feed stable | Wire helps when saw cuts aren’t tight |

| Gas shielding | Bright bead, reduced heat tint | Tune flow, keep cup close, add trailing shield on long runs | Good gas saves you from extra cleaning |

| Passivation after clean-up | Restores corrosion resistance | Pickling/gel/electro-clean → rinse → passivate | Heat tint removal is not optional outdoors |

| Procedure & acceptance | Fewer comebacks, easy sign-off | Basic WPS/PQR, visual criteria, simple records | Do it once; reuse on every job |

Joint types you actually see (and how to set up)

| Joint on handrails | Typical issue | Practical setup | Trap to avoid |

|---|---|---|---|

| Tube-to-tube fillet at 90° | Gap inconsistency around the saddle | Template the saddle, tack at quarters, wobble on | Over-tacking, which hardens distortion |

| Lap joint on return ends | Thin edge overheating | Short dwell, move quick, support from behind | Parking the beam at the edge “just in case” |

| Post-to-base plate | Thick-to-thin transition | Wire assist for fill, slight weave/wobble | Overfill creating a grind marathon |

| Cap on tube end | Blow-through at thin cap | Keep focus slightly in, quick travel | Over-grinding the cap after—you’ll thin it |

| Field splice sleeve | Mismatch on OD/ID | Light bevel, wire to bridge, keep gas shroud close | No gas at the backside; tint creeps in |

Friction points you may face(and fixes)

Heat tint that won’t go away

If the bead looks blue/brown, it’s oxygen. Improve shielding, slow the travel just a hair, or use a trailing shield. Then clean back to bare metal and passivate. Don’t skip passivation for outdoor rails; sea air will find you.Gap too wide at the post saddle

Wire + wobble. Also check saw blade wear—bad blades lie to you. A quick template makes the next saddle repeatable.Rail bows after welding

You overheated or over-tacked. Reduce tacks, spread them, and keep moving. Don’t stack heat in one quadrant.

Gear choices from a Laser Welding Machine Manufacturer that builds for stainless work

You want a handheld unit that’s comfortable, stable on thin material, and friendly for field service. From a Laser Welding Machine Factory perspective, a few picks from BOGONG make this practical and portable:

2024 Popular Portable Handheld Laser Welding Machine— compact unit designed for thin to mid-thickness stainless rail work; comfortable torch and stable arc behavior.

3 in 1 Handheld Laser Welder — weld/clean/cut in one body, handy when you need to trim or de-tint right after a bead.Air-Cooling Handheld Laser Welding Machine — air-cooled convenience for smaller shops and site jobs with limited utilities.Handheld Laser Welder Welding Machine — ergonomic handpiece and consistent puddle control for repetitive joints.

Short production’s process

Fit-up first: square cuts, clean edges, steady clamps.

Tack smart: four quarters, minimal heat, check straightness.

Shielding: dial gas, short nozzle standoff, trailing shield for long seams.

Autogenous when tight; wire + wobble when gaps show.

Keep moving: don’t park the beam; heat stacks fast on thin wall.

Clean tint back to bright metal.

Passivate: gel or electro, rinse and dry.

Blend: belts or scotch pads to match hairline or mirror standard.

Inspect: visual criteria, quick macro on samples if needed.

Document your WPS; next job runs smoother.

Buyer logic

Cost isn’t only the machine: the win is in hours saved on welding + grinding + rework.

Staffing headaches: lasers lower the learning curve for consistent cosmetic work, so new hands get to “good enough” faster.

Field work: handheld units reduce trips back to the shop. Fix it in place, then polish.

Risk: with a basic WPS and acceptance checklist, you standardize quality. Less debate. Fewer callbacks.

Sample acceptance checklist

| Checkpoint | Pass criteria | If not, do this |

|---|---|---|

| Bead appearance | Uniform, no undercut, minimal discoloration | Improve gas, adjust angle, reduce dwell |

| Distortion | Rail straight within your shop limit | Fewer tacks, stagger the sequence, cool between passes |

| Surface color | Silver to light straw; no heavy blue/black | Increase shielding, add trailing shield, clean & passivate |

| Splice fit | Seam closed, smooth transition | Wire assist + wobble, improve saddle template |

| Finish | Brush grain aligned, no deep scratches | Use fresh belts, blend with longer strokes, re-passivate if cleaned |

Commercial value for you

If your team fabricates rails weekly, the handheld approach frees capacity. That’s more projects done, quicker installs, and a better finish standard clients notice. BOGONG LASER®—a Professional CNC Laser Machine Manufacturer—supports global delivery, training, and after-sales. You stay building; we keep the torch ready.

If you want parameters, torch tips, or model matching, welcome to fill the contact BOGONG form. We’ll reply fast.