-

Shunhua Road, Jinan City, Shandong

Galvanized Steel Fiber Laser Cutting Machine Manufacturer

Discover BOGONG Laser’s Fiber Laser Cutting Machine for galvanized steel—boost precision, cut downtime, and maintain zinc integrity. OEM support & global service.

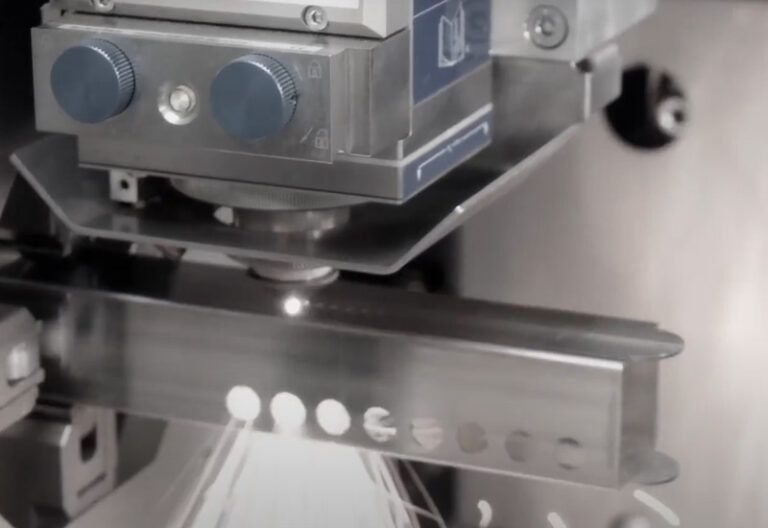

A Galvanized Steel Fiber Laser Cutting Machine is a specialized CNC (Computer Numerical Control) system designed to precisely cut galvanized steel sheets utilizing a high-power density laser beam created through optical fiber. These devices are very effective for reducing different steels, including galvanized steel, which is commonly made use of in applications calling for corrosion resistance.

Why Fiber Laser Wins for Galvanized Steel

Fiber lasers hit the mark when you need speed and precision. They pump high‑intensity beams that vaporize metal instantly. Unlike CO₂ units, you won’t see soot or burnt zinc stains. That keeps your anti‑corrosion coat working and slashes post‑cut clean‑up.

Minimal Heat‑Affected Zone keeps steel from warping.

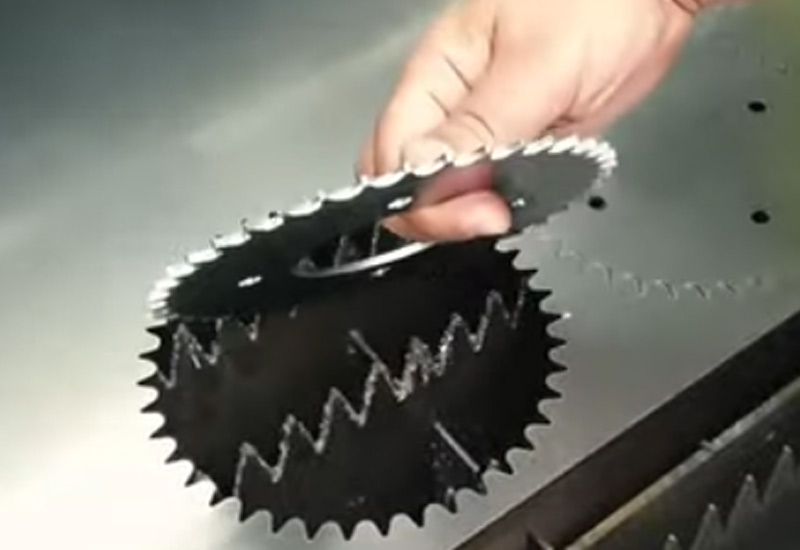

Sharp Kerf means tight parts fit, less rework.

Stable Beam Quality for consistent edge smoothness.

These perks matter in scenarios like automotive roof panel trimming or architectural panel fabrication.

Usage Scenarios

Automotive Parts Preparation

In a mid‑sized auto body shop, galv steel racks needed trimming before welding. Manual methods left burrs and kicked off sparks. Swapping to a Fiber Laser Metal Cutter cut cycle times by half. The shop saw zero edge charring and jumped throughput—no extra grinding or deburring.

Signage Workshop Productivity Boost

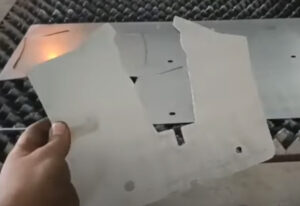

Signage shops handle large zinc‑coated signs that need crisp contours. They tried a handheld plasma cutter first. The results? Jagged edges and a ton of slag. Upgrading to a 5050 Fiber Laser Cutting Machine gave them clean profiles out of the box. They saved on assist‑gas costs and cut maintenance calls to nearly zero.

Structural Frame Fabrication

A metal‑works plant cutting frame components often battled uneven cutting speeds when steel thickness varied. Introducing the Bevel Fiber Laser Cutting Machine smoothed that out. Its adaptive focus lens handled small bevels on the fly, letting the crew knock out chamfers without tool changes.

Common Pain Points—and How We Solve Them

| Challenge | Why It Happens | Fiber Laser Fix |

|---|---|---|

| Dross Build‑Up | High heat zone melts zinc into slag | Precise beam pulse control limits melting, slashes dross by 80%. |

| Warped Parts | Heat‑soak around cut line | Narrow kerf and fast traverse speed reduce heat soak. |

| Nozzle Alignment Drift | Wear, debris, and improper setup | Auto‑calibration feature adjusts nozzle height in real‑time. |

| Erratic Cutting with Varying Gauge | Manual parameter tweaks slow ops | Smart Sense tech auto‑tunes power & speed per material thickness. |

We know you’ve wrestled with those headaches. That’s why BOGONG Laser designs our controls to talk to each other—beam delivery, motion system, and assist‑gas all sync up. You don’t tweak dozens of dials every time the material changes.

Key Features of Top Manufacturers

When you shop around Fiber Laser Cutting Machine Factory offerings, you’ll see similar jargon: IPG source, single‑mode beam, fiber delivery, sealed optics. Here’s how BOGONG Laser stacks up:

Sealed Laser Resonator keeps dust out, extends lifetime.

Auto‑Exchange Nozzle slashes downtime when orifice wears.

Adaptive Focus Module jumps focal spot for thick‑to‑thin contours.

Intuitive HMI with pre‑loaded galv steel recipes.

Compare that to generic units simply listing “high power.” You’ll get more real uptime from smart features than raw wattage.

Troubleshooting on the Shop Floor

You’ll hit snags like kerf width drift or inconsistent edge squareness. Here’s how to nip them:

Dross Inspection: Check post‑cut zinc slag—too much points to wrong assist‑gas pressure.

Nozzle Gap Check: Use calipers or feeler gauge; keep at recommended height.

Beam Path Cleanliness: Wipe sealed optics monthly; dust sneaks in through leaks.

Parameter Validation: Run a corner test on scrap galv plate before full job.

We include a checklist with each 6000W-40KW fiber laser cutting machine for fast startups. You’ll cut setup time and hit optimum cut quality from day one.

How to Choose Your OEM Partner

Picking a Fiber Laser Cutting Machine Manufacturer isn’t just about price per watt. Look for:

After‑Sale Service: On‑site install, remote diagnostics, spare parts guarantee.

Local Support Network: Faster response times beat waiting months for overseas techs.

Customization Options: Beam expanders, special chucks, extra pallets—fit it to your workflow.

User Community: Access to online forums, training videos, and peer tips.

BOGONG Laser serves 9,000+ clients in 160+ countries. Our multilingual site and global B2B focus mean you’ll find docs in your language.

Wrapping It Up

No more chasing down sloppy cuts or wrestling with warped parts. When you pick a Fiber Laser Cutting Machine from BOGONG Laser, you get gear that’s tuned for galv steel, backed by real‑world insights, and ready to roll. Lean on our factory‑direct advantage, global support, and no‑nonsense advice.

Fill out the contact form at bogong to get a custom quote.We’d love to help you.