-

Shunhua Road, Jinan City, Shandong

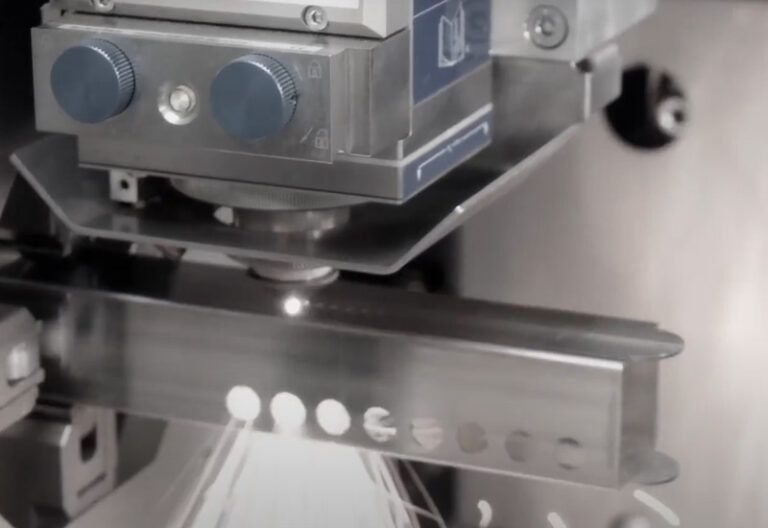

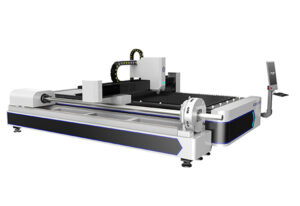

Fiber Laser Cutting Machine for Elevator Door Panels

Elevator door panels need clean edges fast. See how a Fiber Laser Cutting Machine boosts quality, yield, and speed—plus BOGONG setup tips and gear links.

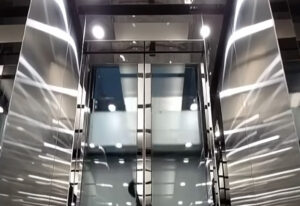

Fiber laser cutting machines are a fantastic option for generating elevator door panels due to their precision, rate, and ability to take care of complex styles with very little material waste. These devices can decrease fancy patterns into stainless-steel and other steels typically made use of in elevator structure and construction, establishing smooth, burr-free sides that are crucial for smooth treatment and visual charm.

Why Are More and More Elevator Manufacturers Choosing Fiber Laser Cutting Machines?

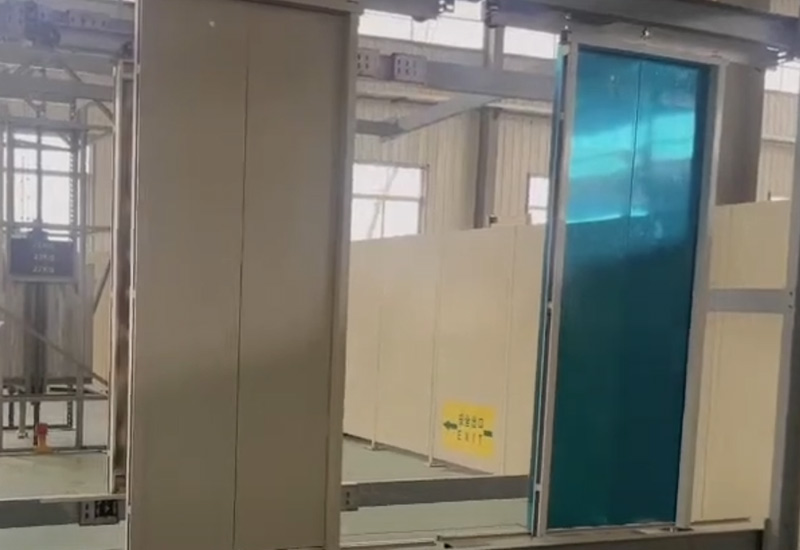

Industry Shift

The market is moving from manual or semi-automated lines to automated, high-precision fiber laser systems. Programs update in minutes. Nesting improves yield. And with the right gas and head setup, you get cosmetic edges that pass the glove test.

Precision Requirements

Door skins, jambs, windows, and trims need tight tolerances for seamless assembly. Fiber lasers deliver stable kerf, controlled corner power, and clean lead-in/lead-out—so parts sit flush, doors track right, and installers stop filing in the field.

Material Versatility

Elevator builds mix stainless (mirror, hairline, PVD), coated sheet, aluminum trims, and structural parts. A Fiber Laser Cutting Machine handles these without changing the whole line. Minimal distortion, low HAZ, surface film intact when you dial the path properly.

Customization Needs

Some project work need rapid prototypes and complex cutouts—windows, handle slots, brand patterns. Fiber lasers cut tight radii and fine details without special dies.

Sustainability Goals

Energy-efficient lasers, optimized gas use, and less rework reduce footprint. You move fewer parts back and forth for polishing.

Challenges Facing Elevator Door Panel Manufacturing

Technical Challenges

Edge cosmetics: hairline or mirror finishes hate oxidation.

Film behavior: wrong film or bad lead-out cooks glue at corners.

Back-reflection: polished stainless reflects; optics and pierce strategy must respect it.

Flatness: long cuts in thin sheet risk potato-chip warp if heat piles up.

Operational Challenges

Cut order chaos: small windows cut first? parts tip; no bueno.

Nozzle concentricity drift: one head bump and gas jet goes sideways.

Mixed materials: swapping gases, nozzles, and liners—if unmanaged—kills uptime.

Nesting discipline: poor tab strategy leads to fly-offs and bent corners.

Market Demands

Short lead times with more variants.

Visible quality that holds up under lobby lighting.

Traceability so assembly grabs the right kit every time.

Predictable cost without surprise rework.

Advantages of Laser Cutting for Elevator Door Panels

| Advantage | What It Solves | Shop Jargon You’ll Hear |

|---|---|---|

| Clean, oxide-free edges | Less polishing on mirror/hairline | “Run N₂, keep it bright” |

| Tight corner control | No “mouse-bites,” smooth windows | “Corner power under control” |

| Minimal HAZ | Flat panels, less warp | “Heat budget in check” |

| Film-friendly paths | No film boil or glue smear | “Don’t dwell at lead-out” |

| Fast changeovers | Multi-SKU in one shift | “Just load the new nest” |

| Better yield | Less scrap per sheet | “Nesting paid for lunch” |

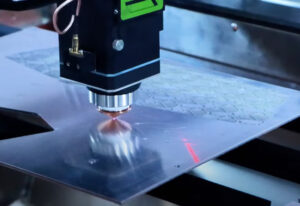

[/vc_column_text][vc_column_text css=””]Here is a video shows how BOGONG’s fiber laser cutting machine cuts steel, which is very helpful for manufacturing elevator door panels.

Fiber Laser Cutting Machines for Elevator Door Panels: Key Features

Nitrogen cutting for cosmetics: Bright edges on stainless. No heat tint. Downstream finishing chills out.

- Back-reflection awareness: Smart piercing and monitoring to protect optics on polished stock.

Lead-in/lead-out strategies: Put them in hidden zones; shorten dwell; arc-style in visible edges.

Kerf and corner libraries: Save recipes by material/finish.

Nozzle concentricity tooling: Quick checks after head bumps keep the jet straight.

Tab (micro-tab) control: Prevent tip-ups on window cutouts; snap clean, sand once.

Automation-ready: Loader, sorter, and bin labeling make kits flow right to bending.

BOGONG in Action

| Step | BOGONG Module | Pain Point Fixed | What You See |

|---|---|---|---|

| Cut skins | Fiber Laser Metal Cutter | Oxidation & burrs on hairline/mirror | Bright edges, low HAZ, less hand work |

| Mix sheet + tube | Laser Plate & Tube Combo Fiber Las er Cutting Machine  | Two queues, two schedules | One plan, smoother takt |

| Bevel/groove | Bevel Fiber Laser Cutting Machine | Grinder time, inconsistent edges | Consistent prep, clean reveals |

| Rails/stiles | Automatic Loading Laser Tube Cutting Machine | Manual loading, delays | Hands-off feed, solid traceability |

| Samples | 5050 Fiber Laser Cutting Machine | Prototyping blocked by big jobs | Quick-turn parts in small space |

Why Choose BOGONG’s Fiber Laser Cutting Machines?

BOGONG LASER® is a Fiber Laser Cutting Machine Manufacturer serving global B2B clients in 160+ countries across metalwork, automotive, signage, electronics, and more. Product range spans cutting, marking, cleaning, and welding; certifications include CE, ISO9001, SGS, FDA, France BV. We offer OEM/ODM, multilingual support, and help you tune nests, gas strategy, and film choices.

Conclusion

Elevator door panels don’t forgive. Fiber lasers do the job when you set them up right: gas choice, optics care, tool-path discipline, nesting that respects part behavior. With BOGONG, you get machines plus the playbook—so panels look sharp, assembly runs smooth, and deadlines stop biting.

Welcome to fill the BOGONG contact form, we’ll get back with practical advice fast.