-

Shunhua Road, Jinan City, Shandong

Fiber Laser Cutting Machine for Aluminum Profile Solar Bracket

Cut aluminum solar brackets faster and cleaner with BOGONG’s fiber laser cutting machines. Explore solutions for every scale and automate your solar frame workflow.

Fiber laser reducing machines are well-suited for reducing aluminum profiles utilized in solar panel brackets. They offer speed, precision, and the capacity to cut intricate forms, making them efficient for this application.

Why Solar Bracket Fabricators Are Switching to Fiber Laser Cutting Machines

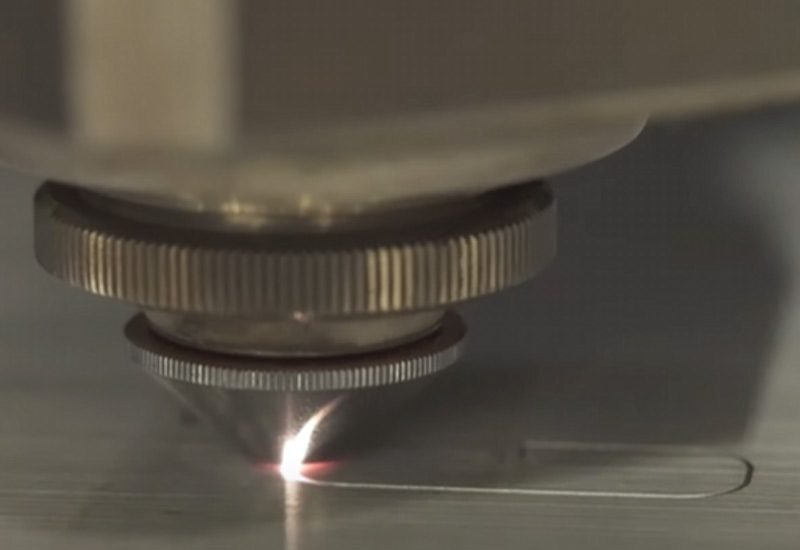

Cutting aluminum isn’t as easy as it looks. It reflects light. It conducts heat fast. That combo makes it a pain for old-school CO₂ lasers. Fiber lasers, on the other hand, work like a charm for mid-thickness aluminum profiles.

With laser sources designed to deliver power straight into reflective surfaces, fiber machines don’t blink—even when faced with mirror-like aluminum. This precision means fewer rejects, cleaner edges, and less post-processing. That alone saves you hours per batch.

Fiber vs. CO₂: Know Your Laser for Aluminum Work

Here’s a straight-up comparison to show you how fiber lasers outperform other methods when it comes to cutting aluminum profiles for solar brackets:

| Feature | Fiber Laser | CO₂ Laser |

|---|---|---|

| Light Absorption on Aluminum | Excellent (high absorption) | Poor (reflection losses) |

| Electrical Efficiency | High (~35%) | Low (~10%) |

| Cutting Speed (Thin Aluminum) | Faster | Slower |

| Maintenance | Low (no mirrors or alignment needed) | High (glass tubes, mirror cleaning) |

| Beam Quality | Tighter focus, cleaner edge | Diffused beam, more slag |

| Cost Over Time | Lower total cost of ownership | Higher long-term maintenance costs |

You don’t just save time—you cut operating costs in the long run.

Key Challenges When Cutting Aluminum Profiles (and How to Handle Them)

Cutting aluminum might sound straightforward, but most shops face three recurring issues:

1. Reflectivity Ruins Beam Delivery

Old machines bounce the laser off the material instead of into it. That’s wasted power and poor cuts. Fiber laser sources, though, come with better coupling to reflective metals like aluminum.

2. Burrs & Melting

Go too slow? You’ll melt edges. Go too fast? You’ll leave burrs. Solution? Dial in the sweet spot using assist gas (typically nitrogen) and real-time piercing control.

3. Oxidation Trouble

Oxidized edges make welding and assembly harder. Using clean nitrogen and keeping the beam sharp prevents that.

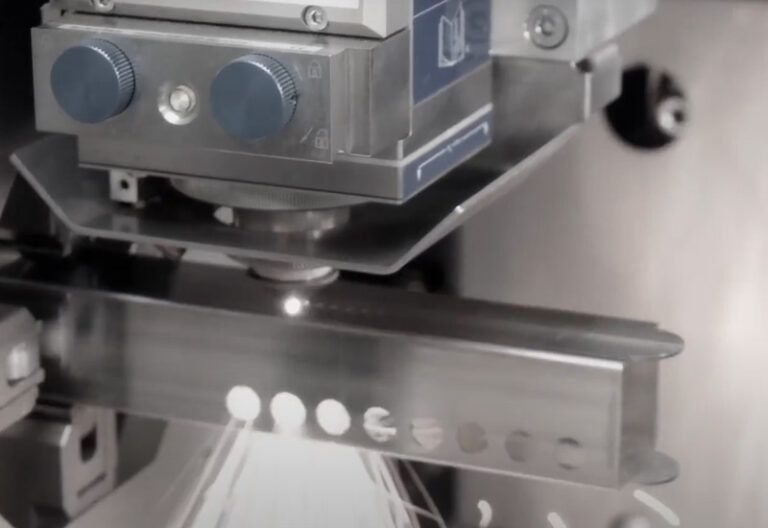

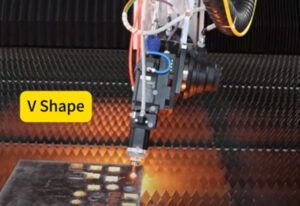

At BOGONG, we’ve helped solar frame shops tune their systems using our Bevel Fiber Laser Cutting Machine, which cuts precise angles and grooves with less post-polishing needed.

Why Automation Matters for Solar Panel Bracket Manufacturing

Mass production needs repeatability. You can’t afford to manually load and unload tubes all day when you’ve got quotas to hit. That’s why automation is the future.

Our Automatic Loading Laser Tube Cutting Machine brings real speed into the game—especially for solar farms ordering in bulk. With programmable logic and smart sensors, the machine handles tubes in and out, non-stop.

A solar EPC contractor in Southeast Asia trimmed two-thirds off their cut-and-assembly time by switching to a fully automated fiber tube system. Same headcount, three times the output.

Real Advantages in Solar Mounting Projects

Fiber laser machines are not just about cutting—they’re about boosting the entire manufacturing workflow.

Precision Fit = Faster Assembly

When your profiles fit together perfectly, you spend less time on the assembly line. That means shorter lead times for large solar farms.

Material Savings

Clean cuts mean no rework. No rework means less scrap. It also helps with sustainability goals, which more clients are asking for.

Scalability

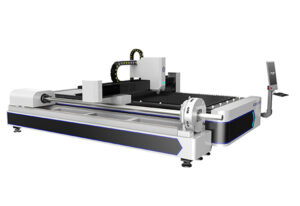

From 100 brackets a day to 10,000 a week? Easy. With machines like the Laser Plate & Tube Combo Fiber Laser Cutting Machine, you can shift between flat sheet and tube without switching systems.

The solar bracket industry is moving fast. Clean cuts and fast turnarounds aren’t nice-to-haves anymore—they’re musts. And if you’re still using outdated equipment, you’re losing time and margin every single day.

Upgrading to a fiber laser cutting machine tailored for aluminum profiles isn’t just a tech upgrade. It’s a strategic move that sets you up for long-term success.

Choosing the Right Fiber Laser Cutting Machine for Your Solar Bracket Business

Some solar setups need compact machines; others need high-wattage powerhouses.

Here’s a quick overview:

| Machine Name | Best For | Key Feature |

|---|---|---|

3020 Fiber Laser Cutting Machine | Ultra-small batch production | Compact footprint, ideal for prototyping |

5050 Fiber Laser Cutting Machine | Medium-scale solar bracket lines | Balance of power and size |

6000W-40KW Fiber Laser | Large-volume solar farms | High-power output for thick or long extrusion cuts |

Smallest Fiber Laser Cutting Machine | Compact frame cutting | Entry-level but still serious performance |

Whether you’re doing flat sheets, tubes, or a combo—BOGONG’s lineup has you covered.

Fiber Laser Cutting Machine Manufacturer or Partner?

BOGONG LASER isn’t just a fiber laser cutting machine factory; we manufacture our systems in-house, test them on real-world materials, and offer custom OEM/ODM tweaks for global customers. Plus, our support team speaks your language—literally. We’ve delivered to 160+ countries and handled 425+ industrial projects.

So whether you’re scaling up, automating, or just starting out—we’ve got the tools and team to help you get there.

Let’s fill the form and talk to BOGONG LASER.