-

Shunhua Road, Jinan City, Shandong

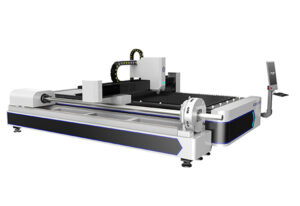

Fiber Laser Cutting Machine for Agricultural Machinery Parts

Make ag parts that just fit. BOGONG fiber lasers cut plate and tube with clean edges, steady takt, and easy scaling—from prototype to real production.

Modern farming hits hard: tighter windows, tougher soils, more uptime pressure.

That’s where precision manufacturing earns its keep; when holes stay round and edges cut true, assembly flows and rework chills out.

Put simply, a Fiber Laser Cutting Machine lets ag manufacturers turn complex frames, wear parts, and tube sections into consistent, ready-to-weld pieces with less fuss. It blends sharp accuracy, steady throughput, and lean operating costs, then plugs into CNC and automation without drama.

Challenges of Agricultural Machinery Manufacturing

Demand for Durability

Ag parts live in dirt, wet, and shock. Edge quality and geometry repeatability protect welds and reduce early fatigue. If your cut drifts, your weld bay will feel it first.

Complex and Varied Designs

Tillage tools, harvest heads, planters—lots of custom brackets, tight slots, small holes. You want crisp contours and locator features that make kits snap together.

Material Diversity

Shops cut high-strength steel, stainless, and abrasion-resistant alloys. They’re all doable on fiber, but the process window matters: sensible pierce, lead-ins, and a heat-balanced path keep edges sound.

High Production Costs & Low Efficiency

Legacy cutting can pile up burrs, tool wear, and rework. Nesting is so-so, handling is clunky, and takt time creeps.

Need for Rapid Prototyping and Scalability

Seasons swing. You need quick prototypes, short pilots, and a clean ramp to steady volume.

Advantages of Fiber Laser Cutting in Agricultural Machinery Production

Superior Precision & Cut Quality

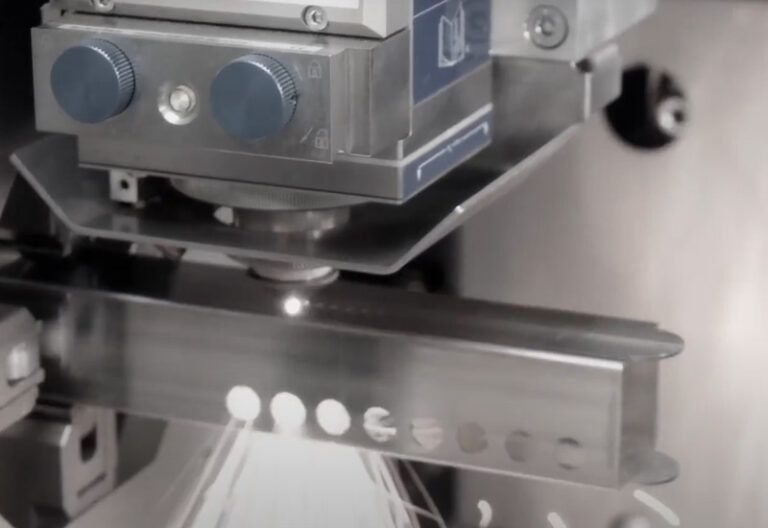

Fiber laser makes a narrow kerf with a small heat zone. Holes stay true. Tabs repeat. Welders tack faster. Less flap-wheel and touch-up, more flow.

High Speed & Productivity

On thin to medium metals, fiber runs fast and stable. With the right pierce routine and height control, cycle time stays predictable and sane.

Energy Efficiency

Fiber tech sips power compared to older methods. You feel it on the bill and in the cooler shop air. Good for cost, good for process stability.

Low Maintenance & Operating Costs

Solid-state design. No mirror trains. Keep the nozzle, protective window, gas purity, and chiller in shape, and the cut stays clean. Boring maintenance is the best maintenance.

Material Flexibility

Carbon steel, stainless, aluminum, coated stock—fiber handles the mix. Tune assist gas and charts to match weld-through and paint later.

Automation & Integration

Easy with CNC nests, barcode flows, auto loaders, and tube handling. Lights-out shifts feel less scary when the recipe is locked and repeatable.

Key Applications of Fiber Laser Cutting in Agricultural Machinery

Cutting of Structural Components

Frames, chassis, brackets, and beams. Accurate edges and holes reduce fixtures and speed the weld bay. Less shim, more fit.

Fabrication of Wear Parts

Plowshares, discs, blades, tines. With disciplined sequencing and edge handling, wear plate cuts clean and stays weldable.

Precision Holes and Contours

Shaft holes, linkages, hydraulic ports. Use proper pierce strategies and smart lead-ins. If a hole tolerance gets tricky, drill or ream after laser.

Custom Part Manufacturing

Fast customize work for OEM variants and spares. CAD to cut without waiting for hard tooling. When a line is down, agility wins.

Prototyping and Small Batch Production

Ideal for R&D parts and seasonal refresh. Prototype, pilot, then roll the same recipe into steady batches when demand hits.

Quick Challenge → Fiber Laser Solution Table

| Challenge in Ag Parts | Fiber Laser Solution | Production Benefit | Shop Note |

|---|---|---|---|

| Burrs and Overtime Grinding | Stable cut charts, optimized gas settings | Reduced post-processing time | Edges are smoother, welds look nicer |

| Hole Ovality in Thicker Sections | Tuned piercing + intelligent lead-ins | Clean holes, bolts fit perfectly | Better torque, fewer “oval fights” |

| Tip-ups and Nozzle Strikes | Micro-tabs + heat-balanced cutting paths | Fewer crashes and downtime | Skeleton remains intact, easier handling |

| Fixture Overload on Frames | Tube laser integrates coping/slotting/holes in one pass | Faster tacking and assembly | Fewer jigs needed, calmer welding bay |

| Seasonal Production Spikes | Offline nesting software + automated material handling | Predictable cycle times | Smooth operations during nights and weekends |

How to Choose the Right BOGONG Machine for Your Needs

Pick by part mix and downstream flow.

Flat plate and mixed gauges

If brackets, guards, and plates eat your day, start simple: Fiber Laser Metal Cutter. Stable edges, easy runs, friendly to daily changeovers.

Plate and tube in one cell

When kits ship with both flats and tubes, a combo line keeps material moving: Laser Plate & Tube Combo Fiber Laser Cutting Machine.

Tube frames, booms, rails

Cut cope, notch, and locator holes in one pass with Automatic Loading Laser Tube Cutting Machine.

Why Choose BOGONG’s Fiber Laser Cutting Machines?

Real build, real support. BOGONG LASER® is a Fiber Laser Cutting Machine Manufacturer and Fiber Laser Cutting Machine Factory with global delivery and on-the-ground training.

Certs that matter. CE, ISO, SGS, FDA—clean audits, smoother imports.

OEM/ODM friendly. Need custom guarding, conveyors, or software links? We handle it.

Prototype to scale. We validate your cut, lock the recipe, then help you scale to bulk order without reinventing the line.

Conclusion

A Fiber Laser Cutting Machine brings clean edges, steady takt, and flexible routing across plate and tube. It slots into automation, respects welders, and scales from prototype to repeat work without drama. That’s how you protect margin and ship on time, even when the season gets wild.

If this sounds like your world, contact us for a free consultation, sample cutting, or factory tour.