-

Shunhua Road, Jinan City, Shandong

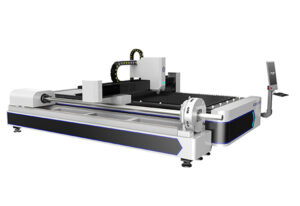

Customized Round Tube Fiber Laser Cutting Machine

Discover custom round tube fiber laser cutting solutions—boost precision, speed, and yield. Partner with BOGONG Laser, your factory-direct fiber laser specialist.

A customized round tube fiber laser cutting machine is a specific CNC system developed to specifically cut different types of round steel tubes and pipelines with high speed and precision. These equipments are necessary in markets needing elaborate designs and effective steel handling, such as vehicle, aerospace, and furnishings production. They use sophisticated fiber laser modern technology to attain clean cuts and marginal waste on products like stainless-steel, carbon steel, light weight aluminum, and copper.

Advantages of Tailored Round Tube Laser Cutting

Micrometer-Level Precision

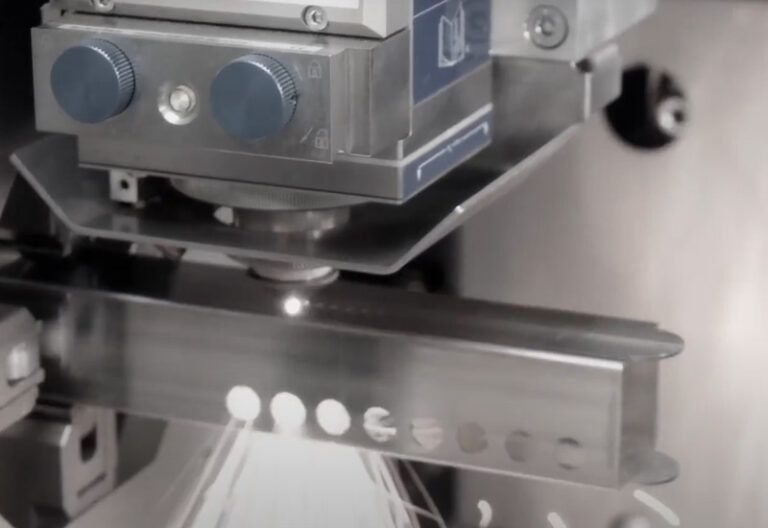

In tube cutting, runout and kerf width can wreck part quality. A custom setup with axis runout compensation and tight beam focus keeps tolerances at the micrometer level. That means you dodge rework, scrap, and endless deburring.

Broad Material Handling

Round tubes come in all metals—stainless steel, carbon steel, aluminum—and even exotic alloys. A one‑size‑fits‑all cutter often stalls on varying reflectivity or wall thickness. A tailored head with adaptive pierce delay and real‑time pump‑power tweak glides through every scenario.

Let’s watch this quick demo showing BOGONG’s fiber laser pipe cutting machine slicing round tubes at blistering speed and pinpoint accuracy.

Fiber Laser Pipe Cutting Machine Round Tube Cut – UNBELIEVABLE Results

Rapid Throughput

Downtime kills margins. When you automate loading, optimize nesting, and dial in gas pressure, you shrink cycle time per tube. High‑rep‑rate diodes and fast‑response scanners blast through metal in record time. That cuts lead times and amps up plant capacity—so you can bid on more jobs and win.

Custom Features to Fix Shopfloor Headaches

Rotary Chuck and Axis Compensation

Tube wobble leads to uneven cuts. A precision rotary chuck with backlash‑free gearboxes locks the tube dead‑center. Add encoder feedback on the rotary axis, and you nix “stair‑step” bevel edges. No more manual chamfering after cutting.

Auto‑Loading Integration

Feeding long bars by hand burns manpower and invites misfeeds. Auto‑feeding systems grip, measure, and position tubes in one fluid motion. You ditch the loading jig and extra operator. Plus, inline ovality sensors catch bad sections before they waste time.

Smart Nesting Software

Manual programming for batch runs wastes hands‑on time—especially when tube patterns vary. Smart nesting software crunches layouts, auto‑rotates parts, and groups similar cuts. That slashes offcut waste and squeezes more parts from your tube stock.

Product Highlights

Here are some top picks for round‑tube cutting:

5050 Fiber Laser Cutting Machine: Small‑diameter tube hero with tiny footprint.

Automatic Loading Laser Tube Cutting Machine: Hands‑free bar feeding that keeps your cell humming.

Bevel Fiber Laser Cutting Machine: Built‑in bevel head for angled cuts—no extra ops.

All‑in‑One Fiber Laser Tube & Sheet Combo: Switch from plate to tube in minutes.

Use Cases

| Pain Point | Custom Feature | Benefit |

|---|---|---|

| Tube slip during high‑speed cut | Encoder‑driven rotary chuck | Consistent kerf, no rework |

| Varying wall thickness | Adaptive pierce delay & power tuning | Clean edge, minimal dross |

| Long setup for batch jobs | Auto‑loading bar feeder | Hands‑off run, fewer manpower costs |

| Complex shape nesting by hand | One‑click nesting software | Faster program time, less waste |

Why Partner with BOGONG Laser

Choosing a specialist like BOGONG Laser means you get more than off‑the‑shelf kit. You tap into a top‑tier Fiber Laser Cutting Machine Manufacturer with CE, ISO9001, SGS, FDA, and BV certifications. They’ve shipped machines to 160+ countries and tackled 425+ projects. As a Fiber Laser Cutting Machine Factory, BOGONG Laser knows tube cutting inside out:

Cutting Range: Sheet to tube, fiber and CO₂

Marking & Engraving: Fiber, MOPA, CO₂, UV

Cleaning & Welding: Pulse/CW cleaning; handheld and fiber welding

Multilingual Support: Manuals and UI in your language

BOGONG Laser tunes each system to your tube diameter, wall gauge, and takt time. Don’t let a generic cutter slow you—go factory‑direct for best lead times and rock‑solid support.

Wrapping Up

Off‑the‑shelf tools might work for basic jobs, but when you juggle tube profiles, varying wall gauges, and tight deadlines, you need a cutter dialed into your workflow. Custom round tube fiber laser cutting machines pack the precision, speed, and flexibility modern shops demand.

BOGONG Laser nails your pain points—tube runout, dross, setup bottlenecks—with purpose‑built solutions and global support. Ready to banish the headaches? Fill in the contact form on BOGONG Laser.