-

Shunhua Road, Jinan City, Shandong

Case Study 500W Pulse Laser Cleaning Machine In Rust Removal

How use a 500W Pulse Laser Cleaning Machine vaporizes rust and paint with no damage. Boost efficiency and get a perfect finish. Here you can meet all your cleaning needs.

Rust is a headache. It is actually that hideous, sneaking issue that decelerates creation, wrecks great parts, as well as simply looks incompetent. For years, our company’ve been actually combating it along with mills, sandblasters, and also harmful chemicals. You understand the drill: it is actually messy, it’s sluggish, and half the moment you wreck the metallic under. It’s a dirty job, and frankly, it costs you money in downtime and labor.

What if you could just… vaporize the rust? Point a light at it and make it disappear, leaving a clean, untouched metal surface behind. That’s what a pulse laser cleaning machine does. And today, we’re diving deep into a real-world case study on the 500W model, showing you how this tech is changing the game for good.

The Old Way vs. The New Way: A Quick Look

- Sandblasting: Creates a huge mess, can warp thin metal, and is rough on the surface.

- Chemicals: We’re talkin’ acids. They’re dangerous to handle, a nightmare to dispose of, and can cause hydrogen embrittlement in the metal.

- Grinders: Slow, manual work that takes skill. One slip, and you’ve gouged the part you were trying to save.

In today’s world of precision manufacturing, you need a solution that’s just as precise. That’s where a modern fiber laser cleaning machine steps in.

Laser Rust Removal: How Does It Actually Work?

The magic word is “ablation.” It sounds intricate, but it’s pretty straightforward. The laser fires super-short, high-energy pulses of illumination at the area. The rust, coating, or even oil layer absorbs this electricity and acquires instantly dissipated in to a very small cloud of dirt, which a suction draws right up.

The metal underneath doesn’t absorb the laser energy in the same way. It reflects it. So the laser only zaps the stuff you want to remove, without ever touching the actual part. No grinding, no chemicals, no damage. Just a perfect, clean surface.

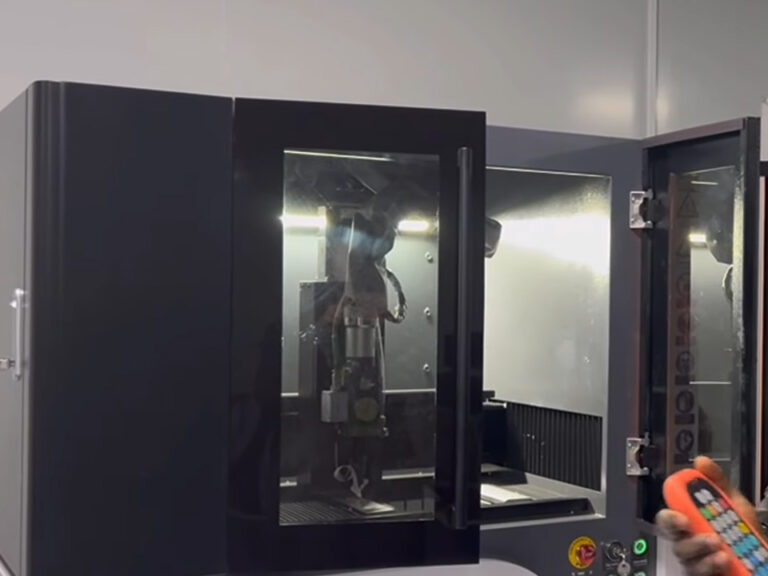

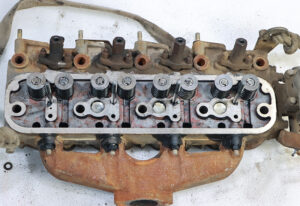

The 500W Laser in Action

So, how does the 500W Pulse Laser Cleaning Machine [cite: 1] perform in the real world? We’re not just talking theory here; we’re talking about what happens when the laser hits the metal. This is the machine that businesses turn to when they need a balance of serious power and precise control.

Unmatched Speed for Industrial Cleaning

When a production line is down, every minute costs money. You can’t afford to spend hours manually cleaning a rusty mold or a dirty weld seam. The 500W laser is built for this kind of pressure. It cleans fast. How fast? Check out this table based on real-world industrial scenarios.

| Feature | Performance in Real-World Scenarios | The “So What” for Your Business |

|---|---|---|

| Cleaning Efficiency | Can clean surfaces at a rate of several square meters per hour, depending on the rust’s thickness. | Massively reduces maintenance time. Much less recovery time implies your devices are creating you amount of money, certainly not costing you. |

| No Substrate Damage | The pulse is so fast (nanoseconds) that heat doesn’t sink into the metal. The base material stays cool and undamaged. | Perfect for high-value parts like engine blocks, aerospace components, or intricate molds where even a tiny scratch is a disaster. |

| Eco-Friendly | Zero chemicals. Zero blasting media. The only consumable is electricity. | No hazardous waste disposal costs. A safer work environment for your team. You can tell your customers you’re using green tech. |

It’s Not Just Power, It’s About Control

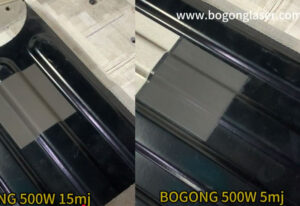

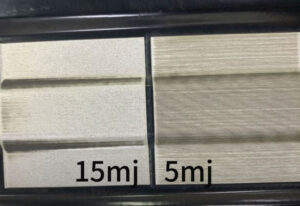

You might believe more energy is actually consistently a lot better, yet along with laser devices, control is king. The energy of the pulse (measured in millijoules, or mJ) is just as important as the power (watts). A higher pulse energy removes material faster, but a lower energy gives you a finer, more delicate touch.

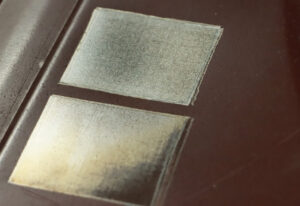

Don’t just take our word for it. Watch this video. We put two 500W machines side-by-side: one with a 5mJ pulse and one with a 15mJ pulse. You’ll see the difference clear as day.

As you saw, the 15mJ setting creates aggressive, bold lines, perfect for blasting away thick rust or multiple layers of paint. The 5mJ setting, however, produces a much finer pattern, ideal for sensitive surfaces or when the final look is critical. Having this control means one laser machine for cleaning can handle a huge variety of jobs.

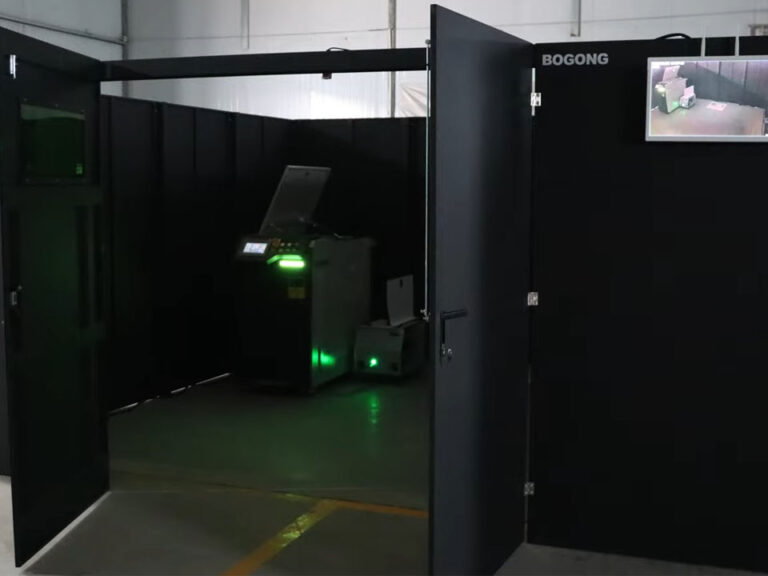

At BOGONG Laser, we offer machines with different laser sources like JPT and Raycus, giving you that exact level of control. Whether you need raw power or a delicate touch, there’s a Pulse Laser Cleaning Machine with Raycus Max JPT Laser configured for your exact needs.

Real-World Uses for a Laser Rust Cleaning Machine

This technology isn’t just for cleaning flat sheets of metal. It’s being used across a huge range of industries.

- Automotive Restoration: Imagine stripping paint and rust from a classic car body without using a single sheet of sandpaper. The laser gets into every curve and corner without warping the panels.

- Industrial Mold Cleaning: Tire molds, injection molds… they all get gunked up. A laser cleaning machine can clean them right in the press, hot and ready to go. No cooldown, no transport, no damage.

- Welding and Bonding Prep: For a perfect weld, you need a perfectly clean surface. Lasers create a pristine, contaminant-free area, leading to stronger, more reliable welds.

- Historical Restoration: Preservationists use lasers to gently clean centuries-old statues and artifacts without damaging the delicate material underneath.

From our powerful 1000W Pulse Laser Cleaning Machine for heavy-duty jobs to more portable options like the Trolley Case type Laser Cleaning Machine, the right tool is out there for your specific application.

Laser Cleaning Machine for Application

Our laser cleaning machine is used in many scenarios and can usually solve many problems for you. Multi-Scenario Laser Cleaning Solutions:

Laser Cleaning Machine for Cars

Laser Cleaning Machine for Metal

Laser Cleaning Machine for Paint

Laser Cleaning Machine for Wood

The Final Word

Switching to a 500W pulse laser cleaning machine is more than just an equipment upgrade. It’s a change in philosophy. It’s about choosing precision over brute force, efficiency over manual labor, and safety over hazardous materials. It’s a tool that not only solves the immediate problem of rust but also makes your entire operation cleaner, faster, and more profitable.

If you’re tired of the old, messy ways of dealing with rust and surface contaminants, it’s time to look at what a laser cleaning machine can do for you.