-

Shunhua Road, Jinan City, Shandong

Bulk Purchase the Best Laser Cleaning Machines for Direct Factory

Upgrade your factory with best laser cleaning machines. Get better, faster results while cutting costs on consumables and labor. Find the right pulse or CW laser direct from the source.

Permit’s be true. That rust, coating, as well as gunk on your parts isn’t simply awful– it is actually a drag on your entire operation. For a long times, our team have actually all relied upon the same old playbook: sandblasting, chemical dips, and a lot of effort. But these procedures are actually disorganized, pricey, and also honestly, dated. You’re consistently buying consumables, dealing with contaminated materials, and also stressing over worker protection. There needs to be a far better method, right?

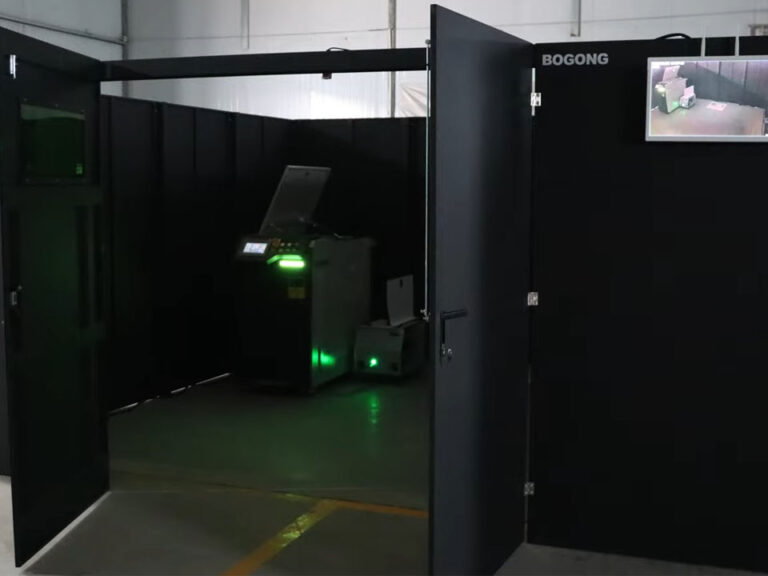

There is. It’s called laser cleaning. Purchasing a laser cleaning machine directly from the manufacturer is about working smarter, not harder. This isn’t some far-off future tech; it’s a sensible remedy that companies are making use of now to get ahead. We at BOGONG Laser have seen it happen with over 9,000 clients in more than 160 countries. Buying direct and in bulk is the single best move to save cash, lock in quality, and future-proof your factory floor.

Why Ditch Old School Cleaning?

We’ve all seen the mess. Sandblasting kicks up clouds of dust that enter whatever. Chemical baths leave you with barrels of toxic sludge to deal with, which costs a fortune and brings ecological regulators knocking. And manual grinding? It’s slow, inconsistent, and tough on your workers.

The real kicker is the hidden costs. You’re not just paying for the sand or the chemicals. You’re paying for:

- Constant Consumables: The bill for sand, solvents, pads, and protective gear never stops.

- Waste Disposal: Getting rid of hazardous waste is a logistical and financial nightmare.

- Worker Recovery time: These old techniques are challenging on folks, leading to health and wellness concerns and time off. A weary laborer by the end of a change won’t wash a component the same way as a clean employee in the early morning. This incongruity can easily screw up your assembly, painting, or installation down free throw line.

These old ways are a constant drain on your resources.

How a Fiber Laser Cleaning Machine Pays for Itself

This is where the fiber laser cleaning machine changes everything. Instead of throwing money away on consumables and waste, you invest in a tool that simply works. The return on investment isn’t just about money; it’s about efficiency, safety, and quality.

| Core Advantage | How It Helps Your Bottom Line |

| Drastic Cost Reduction | The machine’s only real consumable is electricity. One person can operate it, freeing up your team for more valuable tasks. The ROI is surprisingly fast. |

| A Safer, Greener Shop | No chemical waste, no dust clouds. You’re creating a better workplace and avoiding environmental fines. The laser vaporizes contaminants, which are simply vacuumed away. |

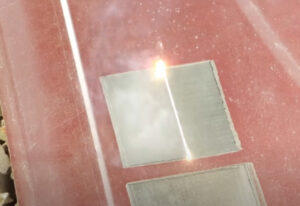

| Unbeatable Precision | Lasers clean only what you want them to clean. They zap the rust, paint, or oil right off without ever touching or damaging the metal underneath. The result is a perfect surface every time. |

| Serious Speed & Efficiency | A laser can clean surfaces at a speed manual methods can only dream of. This means more parts processed per hour and shorter lead times. |

These machines is a huge leap forward. They solve the biggest headaches of industrial cleaning in one go. You get a cleaner product, a safer workplace, and a healthier budget. For many businesses, it’s a no-brainer.

Choosing the Right Tool for the Job: Pulse vs. CW Laser Machine for Cleaning

Not all lasers are created equal. The biggest choice you’ll make is between a Pulse laser and a Continuous Wave (CW) laser. Think of it like choosing between a sniper rifle and a machine gun. Both are effective, but for very different jobs.

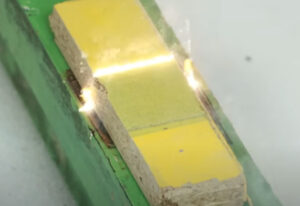

A pulse laser cleaning machine is your sniper rifle. It delivers energy in short, powerful bursts. This gives you incredible control and ensures the metal underneath doesn’t get hot. It’s perfect for delicate work where precision is everything.

- Best scenarios: Cleaning delicate molds, restoring historic items, prepping surfaces for semiconductor bonding, or any job where the base material cannot be altered at all.

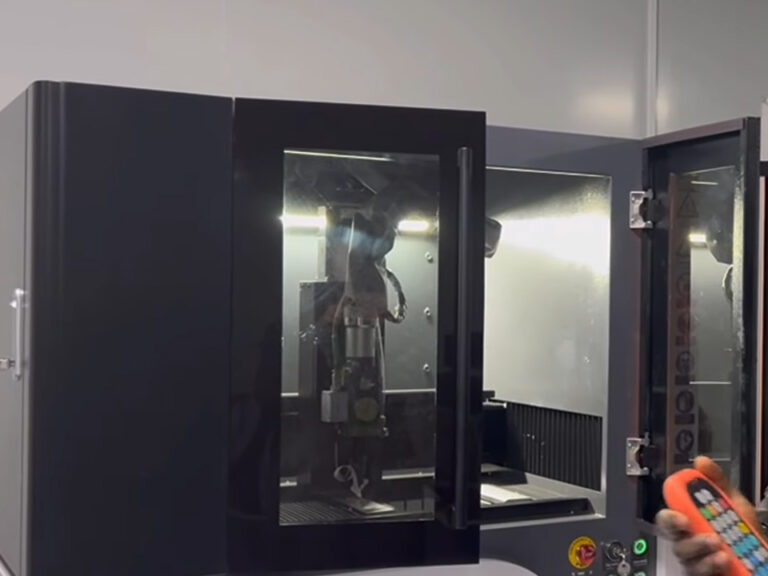

This video shows a 300W Pulse Laser Cleaning Machine in action. You can see how cleanly it strips the surface without any damage.

A CW Fiber Laser Cleaning Machine, on the other hand, is your machine gun. It provides a constant, steady beam of energy. It’s not as delicate, but it’s incredibly fast and powerful. It’s built for heavy-duty jobs where speed is the top priority.

- Best scenarios: Ripping thick rust off large steel plates, stripping paint from ship hulls, or cleaning long sections of pipe quickly.

At BOGONG Laser, we help you figure out exactly what you need. We won’t sell you a machine gun when you need a scalpel. We offer a full range, from powerful 1000W Pulse Laser Cleaning Machines for big jobs to more flexible handheld units for tricky spots.

Why Buying a Laser Rust Cleaning Machine in Bulk Makes Sense

Getting More Bang for Your Buck

This one’s simple: economies of scale. When you buy a fleet of machines directly from the source, you cut out the middlemen and distributors who all add their own markup. The per-unit cost drops, and you get a much better deal. It’s the most direct way to maximize your investment.

Consistency is Key

Imagine having five different cleaning stations in your factory, all using different brands of machines. The training is different, the maintenance is different, and the results are different. It’s a mess. When you bulk purchase a single model, like a Trolley Case type Laser Cleaning Machine for portability, you standardize your entire operation. Your team only needs to learn one system. Your maintenance crew only needs to stock parts for one model. The quality of your cleaned parts is identical across every production line. This consistency is a massive, often overlooked, advantage.

A True Partnership with Your Supplier

When you buy from a reseller, their job is done once they’ve made the sale. When you buy direct from a manufacturer, you’re starting a relationship. You have a direct line to the engineers who designed the machine and the support team that knows it inside and out. At BOGONG Laser, we see ourselves as partners. With our experience across 425+ major projects, we provide ongoing support, training, and advice to make sure you get the most out of your investment. We’re certified (CE, FDA, ISO9001, SGS) for a reason – we stand by our products and our customers.

Where These Machines Shine

You can find these machines transforming factories in nearly every industry.

- Automotive: A laser rust cleaning machine is perfect for cleaning engine blocks, brake components, and prepping metal seams for perfect welds. No more residue means stronger, more reliable welds.

- Aerospace: You can’t risk damaging sensitive aluminum or composite parts with harsh blasting. A pulse laser cleaning machine strips paint and coatings with surgical precision, ensuring the integrity of the underlying material.

- Mold & Die: This is a huge one. Molds are expensive, and cleaning them with blasting or scraping can easily cause damage, leading to costly repairs. Lasers clean out every tiny crevice of a mold without ever touching the steel, extending its life significantly.

- Metal Fabrication: Before you can paint or powder coat a fabricated part, the surface needs to be perfectly clean. A CW Laser Cleaning Machine can blast away mill scale and rust in seconds, creating an ideal surface that paint will stick to like glue.

The list of uses goes on and on. If you have something that needs to be clean, there’s a good chance a laser can do it better, faster, and cheaper.

It’s time to stop letting outdated cleaning methods drain your budget and slow you down. The technology to do it better is here, and it’s more accessible than ever. By thinking strategically and purchasing in bulk directly from a trusted manufacturer, you can equip your entire operation with the best tools for the job. You’ll not only improve your products and your profits, but you’ll also create a safer and more modern workplace.