-

Shunhua Road, Jinan City, Shandong

Bulk Procurement Laser Cutting Machine for Server Chassis Production

Discover the benefits of bulk procurement for laser cutting machines in server chassis production. Streamline operations, reduce costs, and improve efficiency with BOGONG Laser.

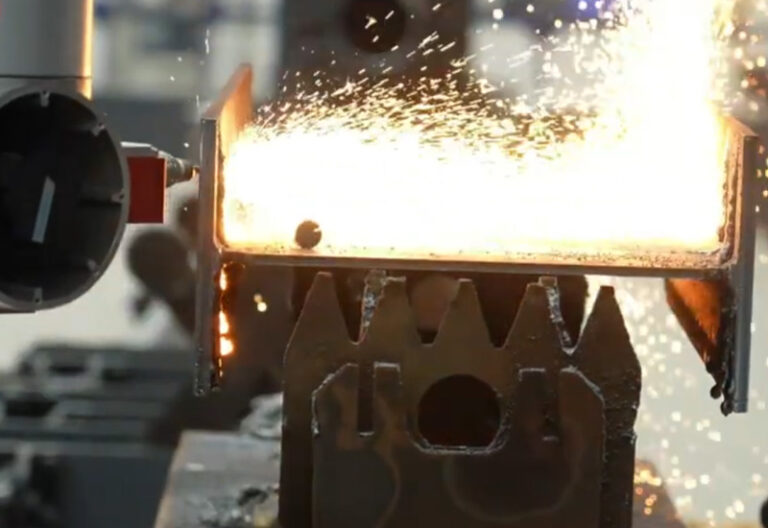

In the ever-evolving world of manufacturing, especially when it comes to producing server chassis, efficiency and precision are paramount. Server chassis production demands equipment capable of delivering intricate designs with minimal error and fast production times. This is where laser cutting machines come into play. Bulk procurement of these machines is becoming more common, as businesses look to streamline operations, reduce costs, and boost output. But why exactly should companies consider investing in a laser cutting machine for server chassis production? Let’s dive in.

Why Laser Cutting Machines Are Ideal for Server Chassis Production

When it comes to server chassis, manufacturers need equipment that can cut through various metals with high precision. Laser cutting machines, particularly fiber laser cutting machines, are perfect for this job. They provide excellent precision in cutting intricate patterns, which is crucial in the production of server chassis where accuracy is key for compatibility with other components.

Another benefit is material efficiency. Laser cutting significantly reduces the amount of waste generated during production. This is essential when dealing with bulk orders, as material costs can add up quickly.

Additionally, laser cutting machines can handle a wide range of materials commonly used in server chassis production, such as stainless steel, aluminum, and carbon steel. The machines are highly versatile, adapting to different thicknesses and shapes of materials, which makes them ideal for mass production in a cost-effective manner.

Key Advantages of Bulk Procurement of Laser Cutting Machines

Cost Savings

The most immediate benefit of bulk procurement is cost reduction. When buying in bulk, companies often secure better pricing and more favorable terms. This is especially useful when outfitting a factory for large-scale production. Not only does buying in bulk lower the upfront cost per machine, but it also ensures that the company will receive the latest, most efficient technology across the entire production line.

Enhanced Efficiency and Consistency

Laser cutting machines are designed to be reliable and consistent. When you invest in several machines, all working in tandem, you’re guaranteed a high level of consistency in the production process. This is vital for server chassis, where even the smallest defect can result in product failure. By investing in multiple machines from a trusted laser cutting machine manufacturer, you ensure that every chassis produced meets the same high standards.

Streamlined Production Process

Bulk procurement can also reduce lead times. With several laser cutting machines in place, manufacturers can run multiple production lines simultaneously. This allows for a faster turnaround time on bulk orders, which is especially important for businesses looking to meet tight deadlines or capitalize on high demand.

Applications of Laser Cutting Machines in Server Chassis Manufacturing

Laser cutting plays a pivotal role in various aspects of server chassis manufacturing. Below are a few key applications:

- Sheet Metal Cutting: Laser cutting is widely used for cutting large sheets of metal into the exact dimensions required for server chassis. This process ensures that each cut is smooth and precise.

- Tube Cutting: Server chassis often include tubes, and automatic loading laser tube cutting machines make it easier to cut metal tubes accurately and efficiently. This process is automated, which minimizes human error and reduces labor costs.

- Custom Grooving: The need for grooves in chassis parts is common, and bevel laser cutting machines excel at creating these precise cuts. These machines can create clean, accurate grooves, which are essential for the assembly of complex server chassis components.

For example, Fiber Laser Cutting Machine offers excellent precision and fast cutting speeds, making it a top choice for businesses looking to ramp up production. Similarly, our 5050 Fiber Laser Cutting Machine is perfect for smaller batches, providing both efficiency and cost-effectiveness.

Overcoming the Challenges in Server Chassis Production

While laser cutting machines provide numerous benefits, they aren’t without their challenges. One of the primary issues faced by manufacturers is ensuring that the machines remain calibrated and maintained to avoid costly downtime. Bulk procurement solves part of this issue by ensuring that companies can keep a backup machine in place while others are being serviced.

Additionally, training and expertise are required to operate these machines efficiently. When investing in multiple units, manufacturers must ensure that their team is trained in using them to maximize productivity and minimize errors.

Conclusion: The Future of Laser Cutting Machines in Bulk Procurement

As the demand for server chassis continues to rise, laser cutting machines will remain a cornerstone of production. By purchasing in bulk, manufacturers can take advantage of lower costs, higher efficiency, and consistent quality in their operations. Companies like BOGONG Laser offer a wide range of high-quality laser cutting machines designed to meet the needs of server chassis manufacturers, providing the precision and power needed for large-scale production.

If you’re considering a large-scale investment in laser cutting machines, BOGONG Laser offers a range of machines like the Bevel Fiber Laser Cutting Machine and Automatic Loading Laser Tube Cutting Machine that can improve your production process.

Ready to Get Started?

If you’re looking for high-quality laser cutting machines for server chassis production, get in touch with us at BOGONG Laser. Our team is ready to help you with bulk procurement solutions that will take your production to the next level.