-

Shunhua Road, Jinan City, Shandong

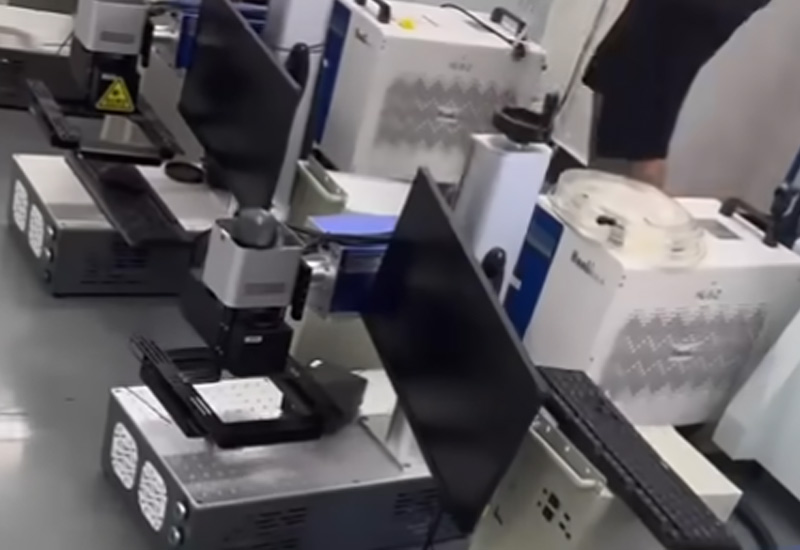

Bulk Procurement Fiber Laser Marking Machine for Automotive Parts

Unlock big savings and seamless traceability by bulk buying fiber laser marking machines. Boost throughput, cut downtime, and simplify compliance.

A Bulk Procurement Fiber Laser Marking Machine for Automotive Parts is a industrial laser system, acquired in big quantities, used to completely etch high-precision marks like identification numbers, logos, and barcodes onto vehicle components for traceability and branding. These machines are excellent for the requiring automotive sector because fiber lasers supply fast, high-contrast, resilient, and wear-resistant marks on numerous products, consisting of steels and certain plastics, with minimal upkeep.

Economies of Scale in Bulk Procurement Fiber Laser Marking Machine

Buying many units at once unlocks volume tiers you simply won’t see on small orders.

Volume Discounts at Fiber Laser Marking Machine Factory

At fleet scale, factories routinely reduce unit pricing. Those savings flow back into your capex so you can fund automation upgrades.

Lower Total Cost of Ownership for Fiber Laser Marking Machine Manufacturer

Bulk deals usually include free on‑site training, extended warranties, and spare‑parts kits. That means no surprise travel fees or emergency part orders later—keeping your TCO nice and low.

Scenario: A brake‑pad supplier replaced 5 legacy engravers with 50 30W Fiber Laser Marking Machines. They reduced per-unit costs and received complimentary lens sets—achieving payback quickly.

Enhanced Traceability & Compliance in Automotive Parts Marking

Strict regs demand permanent, high‑contrast marks on VIN plates, engine blocks, and control modules. Fiber lasers deliver every time.

ISO‑Grade Data Matrix Codes with Fiber Laser Marking Machine

Galvo-scanned beams produce ultra-fine characters that meet relevant ISO standards and remain readable after paint and heat cycles.

Simplified IIoT Audits Across All Lines

Link each unit into your IIoT network, and you get live trace‑back to the exact machine and timestamp. Standardizing on one model also means zero headaches during NHTSA or internal audits.

Check it Out: Want to see these machines in action? Watch this demo:

Auto marking on car parts – China fiber laser marking machine

Boost Operational Efficiency with Fiber Laser Marking Machine

Speed and uptime are everything on a high‑volume stamping line. Bulk procurement helps you run every cell the same way.

High‑Speed Marking Rates

Fiber lasers reach engraving speeds that keep pace with production—so you can tag parts without slowing the line.

Zero‑Consumables, Minimal Maintenance

No inks, no ribbons, no gas. You’ll only ever clean a lens or tune a galvo motor. Small effort, big uptime.

Scenario: A German engine plant swapped 40 spot markers for 40 All‑in‑One Laser Marking Machines. Weekly maintenance time dropped, and technicians shifted focus to process optimization.

Supply Chain Peace‑of‑Mind in Bulk Procurement

Big orders often bring extra perks you won’t get piecemeal.

Service Bundles & Spare‑Parts Kits

Factories throw in lens sets, galvo mirrors, and assist‑gas cylinders for fleets. When something fails, you swap in seconds instead of waiting weeks.

Priority Lead‑Time Guarantees

Need a new laser head? Bulk buyers get top‑of‑the‑line delivery slots.

Example: A Japanese stamping shop locked in 60 units of Handheld Fiber Laser Marking Machine 20W, 30W, 50W .They also scored a rapid swap‑out SLA on critical optics, slicing unplanned downtime to almost zero.

Fleet‑Wide Scalability & Integration Scenarios

One hardware standard means one software standard—and that makes scaling a breeze.

Turnkey IIoT Connectivity

Bulk buys usually bundle pre‑configured IIoT modules. Hook up to MES or ERP without custom PLC coding.

Unified Operator Training

Train once, deploy everywhere. No retraining when you swap to a new batch—operators already know the UI, the maintenance routine, and the safety checks.

Use Case: A Korean transmission maker tied 45 laser markers into its SAP dashboard. . Real-time mark verification shortened QA cycles—with no custom integration work.

Conclusion

Bulk procurement of fiber laser marking machines does more than trim your sticker price. It syncs your entire marking strategy—cost savings, traceability, throughput, and supply‑chain security. Partner with BOGONG Laser®, and you’ll get CE, ISO 9001, SGS, and FDA‑certified gear with global support across 160+ countries. Ready to scale your marking fleet? Let’s chat.