-

Shunhua Road, Jinan City, Shandong

Brass Fiber Laser Cutting Machine Manufacturer

BOGONG Laser offers precise Brass Fiber Laser Cutting Machines for OEM. Discover high-speed, dross-free cutting solutions.

BOGONG offer a range of fiber laser cutting machines designed to handle brass, often with features like high-power fiber laser sources, intelligent control systems, and robust mechanical designs for accurate cutting. Let’s break down what really matters when you shop for a Fiber Laser Cutting Machine for Brass.

Wavelength Perks That Make a Difference

Brass reflects a ton of laser energy. Traditional CO₂ lasers just bounce off and leave you chasing dross and rough edges. Fiber lasers have shorter wavelengths that are a perfect match for brass, resulting in increased absorption. You’ll see:

Cleaner kerf: Less dross to knock off.

Higher edge quality: Smooth cuts without serration.

Lower rework: Fewer scraps, fewer headaches.

Case: Smallest Fiber Laser Cutting Machine

Take the Smallest Fiber Laser Cutting Machine. Shops cutting thin brass plates report way less reflectivity damage. They skip the expensive cer‑coatings and get straight into production. That’s a win when you’re on tight lead times.

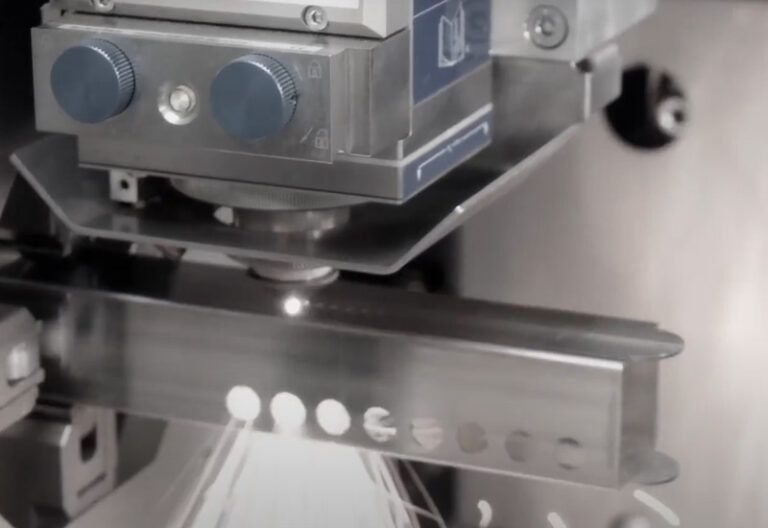

Smallest Fiber Laser Cutter for Stainless Steel Brass

Factory Snapshot: 6000W–40KW Fiber Laser Model

At our Fiber Laser Cutting Machine Factory, the 6000W–40KW series handles most brass jobs. Shops report a noticeable uptick in throughput when they shift from lower‑power lasers. No fancy parameters—just steady, reliable slicing backed by powerful diodes.

Power and Throughput

With the right power range, you slice thicker sections faster. What you get:

Shorter cycle times: Hit your daily quotas without burning out your team.

Stable beam: Consistent focus means consistent quality.

Strong enough for moderate gauge: Nail up to a few millimeters without stepping up machinery tiers.

Process Fine‑Tuning for Crisp Edges

Brass loves to throw curveballs: heat distortion, dross, undercut. Nailing process settings cures these pains:

Beam focus drift compensation keeps your spot size locked.

Optimized scan paths spread heat evenly.

Assist gas choice (nitrogen vs. air) controls oxidation and blow‑out.

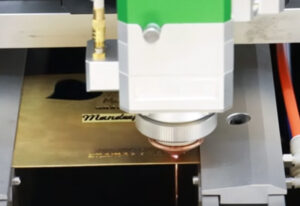

Industry Scenario: Bevel Fiber Laser

The Bevel Fiber Laser Cutting Machine nails edge prep for thick brass plates. Shops dial in focus offsets and gas pressures once—and stay dialed in. That cuts edge cleanup time by a solid chunk.

Automation and Running Costs

Labor eats margin. Automated loading and unloading means fewer hands in the loop and lower OPEX. Think:

Unmanned shifts: Midnight runs without night‑shift premiums.

Repeatable setups: Less operator error on batch jobs.

Data tracking: Real‑time cut logs help you optimize scrap rates.

Use Case: Automatic Loading Laser Tube Cutting Machine

Our Automatic Loading Laser Tube Cutting Machine slashes manual handling. Brass tubes and rods feed in, get sliced, and stack out. The result? Fewer pinch‑point injuries, leaner staff, and a healthier bottom line.

Side‑by‑Side Snapshot

| Key Factor | Benefit | Typical Improvement |

|---|---|---|

| Wavelength | Better absorption, fewer reflections | Edge quality ↑, rework ↓ |

| Power span | Faster cuts on medium gauges | Throughput ↑ |

| Beam focus & scan path | Minimal heat‑affected zones | Clean cuts, less dross |

| Automation | Lower labor costs, higher uptime | OPEX ↓, MTBF ↑ |

Use Cases

A jewelry maker in Italy swapped to BOGONG’s brass‑ready model. Dross vanished, and clean cuts became the norm.

An electronics shop in Mexico automated tube runs and cut scrap by a third—no night‑owl crews needed.

A sign‑maker in Australia installed a bevel‑capable unit to prep thick letters. They trimmed post‑cut grinding by half.

How to Pick Your Machine

Define your use cases: Sheet vs. tube? Heavy vs. fine cuts?

Check beam quality: Look for stable M² values.

Assess factory support: Training, spare parts, remote diagnostics.

Scope automation: Do you need loading, sorting, or vision guidance?

BOGONG Laser is an OEM/ODM CNC Laser Machine Manufacturer. We back every unit with global service, CE/ISO/FDA/SGS certifications, and multilingual support. No crazy lead times—just fast answers.

Wrapping Up

Brass cutting is a balance of tech and tactics. You need the right wavelength, enough power, smart process tweaks, and lean automation. BOGONG Laser brings all that together in a Fiber Laser Cutting Machine Factory designed for brass’s quirks. Whether you’re building prototypes or running mass‑production, our gear adapts.

Fill out the contact BOGONG form and let’s talk.