-

Shunhua Road, Jinan City, Shandong

Best Metal Laser Cutting Machine Buying Guide

Find the ultimate metal laser cutting machine guide: compare fiber vs. CO₂, power, materials, and pick the perfect BOGONG Laser for your shop.

Intro: Why Your Workshop Needs a Laser Cutter That Doesn’t Suck

Whether you’re slicing through stainless steel for aerospace parts or crafting delicate jewelry from brass, your laser cutter is the backbone of your operation. But here’s the kicker—most buyers get it wrong. They overspend on overkill machines or cheap out on tools that can’t handle a soda can. Let’s fix that.

1. The 3 Questions That’ll Save You $50K+

Before you even think about hitting “buy,” ask:

- “Am I a garage warrior, a side hustler, or running a full-scale factory?” (Translation: Hobbyist, entrepreneur, or industrial user?)

- “What’s my material kryptonite?” (Thin sheet metal? Thick titanium? Gold?)

- “Do I need a scalpel or a chainsaw?” (Precision vs. raw power.)

Real Example: A Detroit auto parts supplier wasted $80k on a 12KW beast only to realize their 2mm aluminum sheets could’ve been handled by a 3KW machine. Don’t be that guy.

2. So what factors should be considered when purchasing Metal Laser Cutting Machine

Now, let’s dive in:

2.1 Laser Types: Fiber vs. CO₂

Why Wavelength Matters

Fiber lasers emit at around 1,064 nm, roughly ten times shorter than CO₂ lasers (10,600 nm). That shorter wavelength concentrates energy into a tighter spot, which boosts absorption in steel, stainless steel, and aluminum—so you’ll see faster cut speeds and finer kerf widths.

2.2 Material Forms: Plate, Tube & 3D Cutting

Plate Cutting

Standard sheet sizes like 3 × 1.5 m (3015) fit most shop floors. If you often process larger sheets or custom panels, look for BOGONG Laser machines with extended bed lengths—up to 6 m on select models.

Tube & Profile Cutting

Switching between flat sheets and tubular workpieces requires a tube-cutting attachment or a dedicated combo machine. BOGONG Laser’s Laser Plate & Tube Combo Fiber Laser Cutting Machine handles both without swapping heads, trimming setup time.

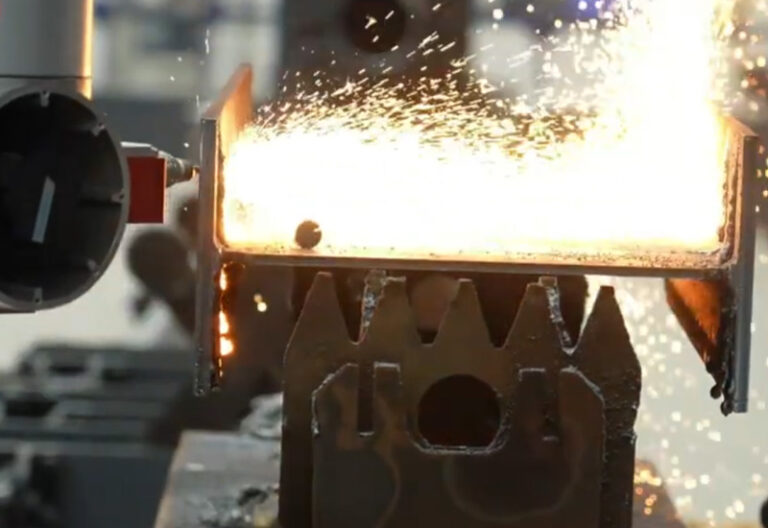

3D / Robotic Cutting

For complex parts like automotive heat-formed components, a 5-axis or robot-mounted laser can perform bevel cuts and contouring in one pass. BOGONG’s Bevel Fiber Laser Cutting Machine tackles chamfering and groove cutting in scenarios where edge prep matters.

2.3 Key Buying Considerations

Carbon steel: Up to 12 mm on a 2 kW fiber laser; thicker plates demand more power.

Stainless steel: Clean cuts up to 6 mm on 1 kW; 3 kW and above handle 20 mm+.

Aluminum & non-ferrous: Plan for 20–30 % slower speeds than steel at the same thickness.

Always check specs for continuous-duty cut vs. maximum burst cut—running at max power nonstop will shorten component life.

3. Wattage Wars: Why Bigger Isn’t Always Better

| Power Range | Best For | Bogong’s Pick |

|---|---|---|

| 1KW-3KW | Thin sheets (<10mm), jewelry, artisanal work | Smallest Fiber Laser Cutter |

| 4KW-6KW | Mid-thickness metals (10-20mm), automotive parts | 5050 Fiber Laser |

| 8KW-40KW | Thick plates (20mm+), heavy industrial jobs | 6000W-40KW Monster |

Pro Tip: Need to cut both pipes and plates? Check out Bogong’s laser cutting machine for metal.

4. Industry Hacks Your Supplier Won’t Tell You

- “Kerf Matters”: A smaller kerf (cut width) = less material waste. Bogong’s beam quality (≤0.1mm) means you’re not flushing cash down the drain.

- “Assist Gas Secrets”: Nitrogen for clean cuts on stainless steel, oxygen for faster carbon steel slicing. Cheap machines skimp on gas systems—leaving you with rusty edges.

- “Speed vs. Precision”: Want both? Look for “high-frequency pulse” tech (Bogong’s Bevel Cutter nails this).

5. In Addition to Choosing the Machine, Choosing the Service is Also Important

4.1 Software & Workflow

Nesting Engine: Efficient material utilization reduces scrap – BOGONG Laser integrates RDWorks Lite software and supports LightBurn for simple parts.

CAD/CAM Compatibility: Make sure your DWG or DXF files import cleanly.

User Interface: Touchscreen features intuitive nesting visuals that allow you to reposition parts on the fly.

Automate repetitive tasks with macros to save time on high-volume production.

4.2 Safety and Training

According to the IEC 60825 standard, industrial laser cutting machines are classified as Class 4 and require interlocks, warning lights, and safety goggles appropriate for your wavelength. BOGONG Laser equips each system with guardrails, exhaust interlocks, and operator training packages to ensure that you meet regulatory requirements from day one.

4.3 Budget and After-Sales Support

Upfront costs: Entry-level 1 kW fiber systems start at around $10,000-$30,000; mid-range 2 kW systems are between $30,000 and $90,000; high-power industrial equipment is over $200,000.

Total Cost of Ownership (TCO): Consider power consumption ($0.07 to $0.12/kWh), gas usage, and maintenance kits. Fiber lasers typically cost half as much per hour to operate as CO2 lasers.

Warranty and Training: Choose a supplier that offers at least a two-year warranty and on-site commissioning.

But don’t worry, it’s usually not that expensive. You need to choose the relevant machine according to your business and avoid choosing a machine that is not suitable for your business.

BOGONG Laser’s major consumable parts are covered by a one-year warranty, with an optional extended warranty of up to five years(The warranty period of different machines is different, which depends on the situation). In addition, remote diagnostics can reduce the number of service visits by half.

6. Final Word: Why Bogong?

We’ve covered everything from laser physics and assist gas choices to real shop stories and side-by-side specs. Now, you know how to read a datasheet like a pro, spot the real-deal beam quality numbers, and avoid hidden maintenance traps.

If you’re ready to slash cycle times, cut burrs out of your workflow, and see ROI in months rather than years, check out BOGONG Laser’s lineup. Their machines combine rock-solid reliability, intuitive software, and local support that actually answers your call.

Here’s a snapshot of BOGONG Laser’s top metal cutting models. Follow the links to dive deeper into specs and pricing.

| Model | Type | Power Range | Work Area | Ideal Scenario | Link |

|---|---|---|---|---|---|

5050 Fiber Laser Cutting Machine | Fiber (sheet) | 500 W–1 kW | 300 × 200 mm | Prototype & light fabrication | View 5050 Fiber Laser Cutting Machine |

6000W–40KW High-Power Fiber Laser | Fiber (sheet) | 6 kW–40 kW | 3 × 1.5 m (standard) | Industrial batch cutting | View 6000W–40KW High-Power Fiber Laser |

Automatic Loading Laser Tube Cutting Machine | Fiber (tube) | 1 kW–3 kW | Dia. 20–219 mm | Tube & profile fabrication | View Automatic Loading Laser Tube Cutting Machine |

Bevel Fiber Laser Cutting Machine | Fiber (bevel cuts) | 1 kW–3 kW | 3 × 1.5 m + beveled head | Chamfering & groove cutting | View Bevel Fiber Laser Cutting Machine |

Laser Plate & Tube Combo | Fiber (combo) | 1 kW–3 kW | 3 × 1.5 m; Dia. 20–219 mm | Versatile mixed workloads | View Laser Plate & Tube Combo |

Look, we’re not here to shill. But when a single machine can handle tiny 3020 projects and 40KW behemoth jobs, it’s hard to ignore. Plus, their ODM/OEM flexibility means you’re not stuck with a one-size-fits-all solution. Ready to get cutting? Visit BOGONG Laser’s laser metal cutting machine category to request a quote, schedule a demo, or dive deeper into specs.