-

Shunhua Road, Jinan City, Shandong

Best Fiber Laser Cutting Machines for Sheet Metal Fabrication (2025)

Find top sheet metal laser cutting machines for 2025. Achieve higher throughput, pinpoint precision, and cut operating costs up to 30% with advanced fiber laser technology.

Best Fiber Laser Cutting Machines for Sheet Metal Fabrication (2025)

In the fast-paced world of sheet metal fab, you need gear that keeps up. Fiber laser cutters have leapfrogged old-school CO₂ setups, delivering insane speeds, tight tolerances, and lower juice bills. This guide digs into what really matters—specs, throughput, upkeep, and the next-gen tricks—so you can pick the right machine for your scenario. Plus, we’ll spotlight how BOGONG Laser stacks up with real-world examples.

Fiber Laser Cutting Machine Performance & Scenario Fit

Power, Speed & Cut-Thickness Matching

When you shop Fiber Laser Cutting Machines, you gotta eyeball three big numbers: laser power (kW), max sheet-metal thickness (mm), and cutting pace (m/min). For light-gauge parts, 1–2 kW units shred up to 6 mm at 30 m/min. Bump to 4–6 kW, and you’re slicing 25 mm plates at 100 m/min—no sweat.

- Low-power rigs (1–2 kW): fab benches, prototyping

- Mid-range (3–4 kW): general fab, signage, thin-wall tube

- High-power (6–10 kW+): heavy-duty steel, large-batch runs

Scenario Tip: If you juggle small jobs and occasional thick-plate runs, grab a 4 kW machine with auto-nozzle changer. It’s a Swiss Army blade for mixed workloads.

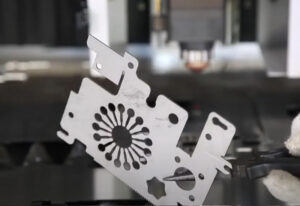

Beam Quality (M²) & Nest Optimization

That M² number isn’t just jargon—it tells you beam focus and edge finesse. M² < 1.3 machines cut fine contours and keep kerf widths down. Couple that with smart nesting software, and you boost material yield without manual CAD voodoo.

Production Efficiency & Edge-Quality Gains

High-Dynamics Control vs. Legacy Systems

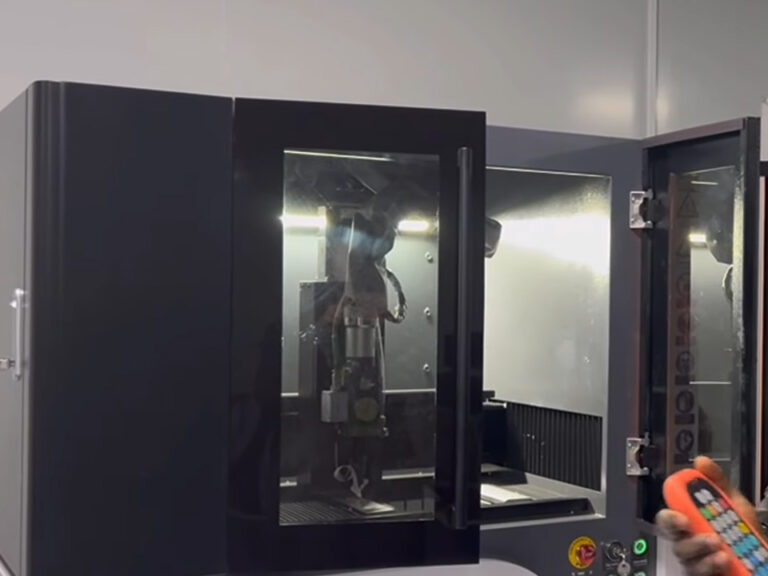

Most cutters still run herbivore-speed motion controllers, throttling fiber lasers to dodge warpage. BOGONG Laser flips that script: they use high-dynamics control boards and Janpan Servo motors to wring every mm/s out of the beam, driving cycles down and throughput up.

Automated Swapping & Predictive Maintenance

Auto-head changer isn’t a frill—it slashes idle time. Factor in IoT-enabled sensors that flag lens fouling and gas-line leaks before they trip you up. This predictive maintenance cuts unscheduled downtime by up to 30%.

Cost Efficiency & OPEX Reduction

Fiber vs. CO₂: Energy & Lifetime

Fiber lasers suck down 20–30% less power and boast diodes rated for 100,000+ hr. CO₂ lamps need swapping every 10–15k hr. Over a machine’s life, fiber’s lower energy draw and fewer lamp changes can cut total cost of ownership (TCO) by 25–40%.

Lean Maintenance & Spare-Parts Strategy

Heavy-duty cast-iron frames on BOGONG rigs hold alignment tight, so you swap parts less often. Their modular drives and plug-and-play optics translate to quick in-house fixes—no two-week OEM lag.

Industry Trends & Next-Gen Innovations

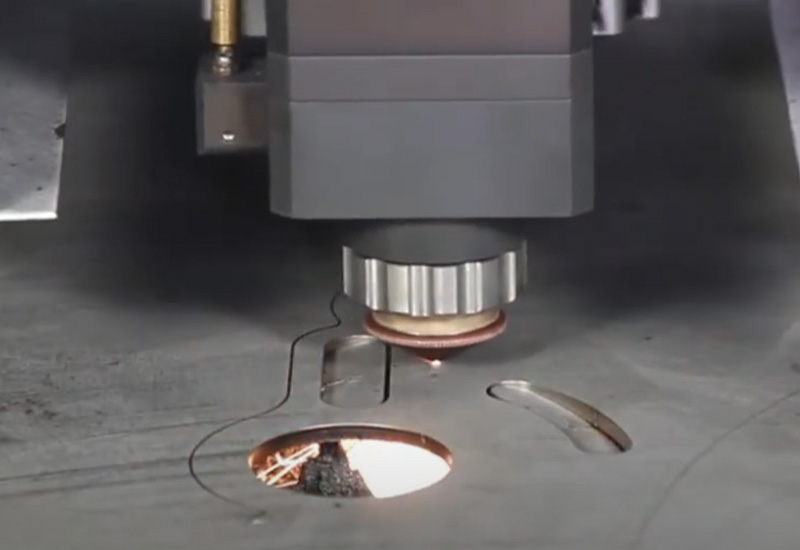

- Tilt-Head Cutting: angled bevels and 3D profiling without re-fixturing

- Chip-Blow Systems: high-pressure air knives clear slag for mirror-smooth edges

- Edge-Assist Sensors: automatic focus tracking on warped sheets

- Smart Nesting AI: pattern recognition tweaks nests on the fly for funnels, brackets, and odd-shape parts

Catch a quick rundown of these features in action:

Case Study Snapshots: BOGONG Laser in Action

| Scenario | Machine Model | Throughput Gain | Edge Tolerance | ROI Impact |

|---|---|---|---|---|

| Automotive Brackets | BOGONG 5050 Fiber Laser Cutting Machine | +45% cycle speed | ±0.05 mm | Payback in 8 mo |

| Custom Signage | BOGONG 3020 Fiber Laser Cutting Machine | +30% yield (nest) | ±0.03 mm | 20% OPEX savings |

| Heavy-Gauge Chassis | BOGONG 6000W-40KW Fiber Laser Cutting Machine | +60% throughput | ±0.08 mm | ROI < 12 mo |

Data based on client deployments in NA and Europe over 2024–25.

Comparative Overview of Top Fiber Laser Cutters (2025)

| Brand & Model | Power (kW) | Max Steel Thickness (mm) | Cut Speed (m/min) | Beam Quality (M²) | Price Tier |

|---|---|---|---|---|---|

| BOGONG FC4020 | 4 | 20 | 90 | 1.2 | Mid-High |

| RivalCo X6 kW Fiber Cutter | 6 | 25 | 100 | 1.3 | High |

| MakerLaser Pro 2 kW Bench Unit | 2 | 8 | 40 | 1.1 | Mid |

| SheetFab Ultra 10 kW | 10 | 30 | 110 | 1.4 | Premium |

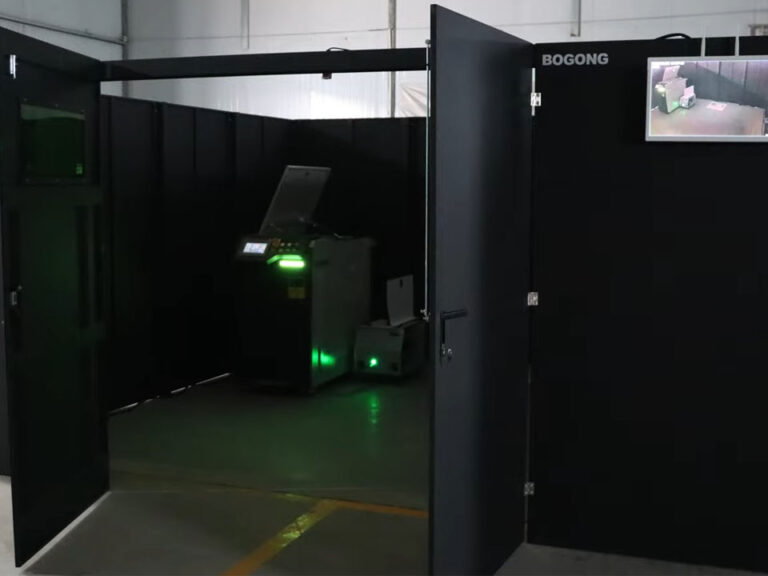

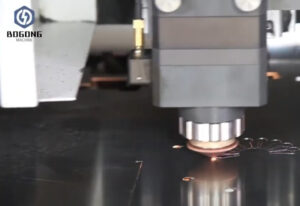

Laser Cutting Machine for Sheet Metal Results Showcase Images

Laser cutting sheet metal produces clean edges with minimal burrs or warping.

Why BOGONG Laser Deserves a Look

You’re looking for consistent throughput, killer edge quality, and payback that doesn’t feel like waiting for paint to dry. BOGONG Laser delivers:

- High-dynamics control and Janpan Servo drive—no more throttled cut-paths.

- Rigid, foundation-free frames machined in one pass, so alignment stays locked.

- Modular optics & smart sensors for fast swaps and zero-surprise maintenance.

- Global B2B backing—9,000+ clients in 160+ countries trust BOGONG Laser for turnkey OEM/ODM setups.

Explore the full lineup here: