-

Shunhua Road, Jinan City, Shandong

Automating Laser Cutting in Smart Manufacturing

Upgrade your workshop with BOGONG Laser's Automating Laser Cutting solutions. Boost productivity and precision with our smart fiber laser machines.

If you’re in manufacturing, you recognize the pressure gets on. Margins are tight, locating knowledgeable labor is a constant struggle, and your customers anticipate quicker turn-arounds and flawless top quality. You’re most likely asking on your own: “Exactly how do I not just endure, yet actually win in this setting?” The answer isn’t about pressing your team harder; it’s about fundamentally altering the game with a smarter technique.

This is where Industry 4.0 comes in. It’s not some far-off, futuristic idea; it’s the functional plan for the contemporary factory, and at its core lies automated laser cutting. This is the change from just having devices that reduced steel to constructing a smart, interconnected system that drives your whole business onward. At BOGONG Laser, we’re not just spectators to this revolution; we are active partners in it. With a track record of serving over 9,000 clients across more than 160 countries, we’ve learned what it takes to transform a traditional shop floor into a powerhouse of productivity and precision.

Demystifying Industry 4.0 Automating Laser Cutting in Smart Manufacturing

Let’s cut through the jargon. Industry 4.0 is the fourth major leap forward in manufacturing. At its heart, it’s about one thing: data. It’s about generating data from every part of your operation, sharing it instantly, and using it to make intelligent decisions automatically. This produces a “smart factory” that is extra effective, agile, and profitable.

The Four Pillars of the Smart Factory

To understand its power, you just need to grasp its four core components:

- The Internet of Things (IoT): Think of this as giving your machines a nervous system. We embed sensors in our laser cutters that act like eyes and ears, constantly monitoring everything from temperature and power consumption to the status of a nozzle. This live feed of information is the foundation of a smart factory.

- Artificial Intelligence (AI) & Machine Learning (ML): If IoT is the nervous system, AI is the brain. It takes the massive stream of data from the sensors and learns from it. It can predict when a part might fail, automatically adjust cutting parameters for a new material, or calculate the most efficient way to cut a complex shape.

- Automation & Robotics: This is the muscle. It’s about using robotic systems to handle the repetitive, physically demanding, and time-consuming tasks. This includes loading 2-ton sheets of metal, unloading thousands of finished parts, and sorting them for the next stage of production, all without human intervention.

- Cloud Computing & Data Analytics: This is your command center. It allows you to access all this data and control your systems from anywhere in the world. You can monitor production on your tablet, analyze efficiency reports, and manage multiple machines from a single, unified dashboard.

Why This Matters for Your Business

This technology is impressive, but what does it actually mean for your profit and loss statement? It translates directly into tangible business outcomes: sharply reduced operating costs, the agility to take on custom jobs profitably, near-perfect quality control that builds customer loyalty, and ultimately, higher, more predictable profits.

From Dumb Machine to Smart Asset

An older machine simply follows a preset command. A BOGONG smart laser cutter, however, has a conversation with the material, the software, and the operator. It senses, adapts, and optimizes on the fly. This evolution from a dumb tool to a smart asset is the key to unlocking the full potential of your production floor.

How BOGONG Laser Systems Embody Industry 4.0 Principles

We design our machines to be the pillars of your smart factory. Here’s how:

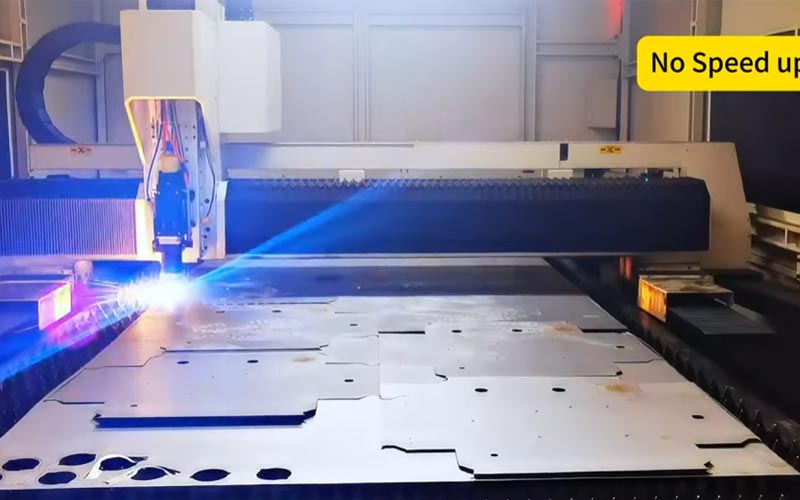

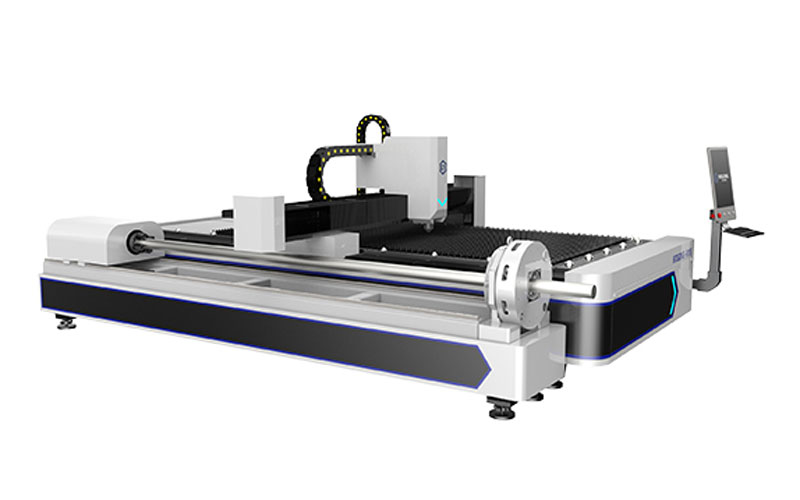

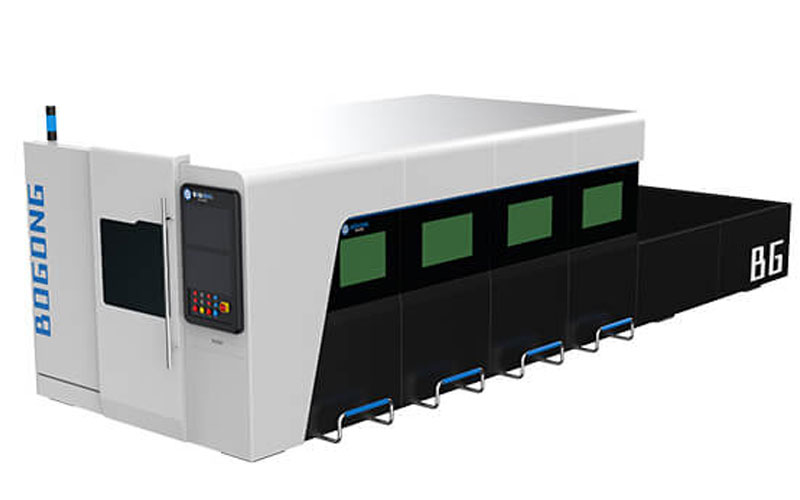

Intelligent, Self-Adjusting Machines: Our Fiber Laser Cutting Machine is a prime example. It’s equipped with sensors that provide real-time feedback. If the material thickness varies slightly, the system adjusts the power and focus automatically to ensure a perfect, consistent cut every time. This eliminates the guesswork and the need for a master-level operator at every machine. For heavy-duty applications, a 6000W-40KW High Power Fiber Laser Metal Cutting Machine provides both immense power and the intelligence to wield it precisely

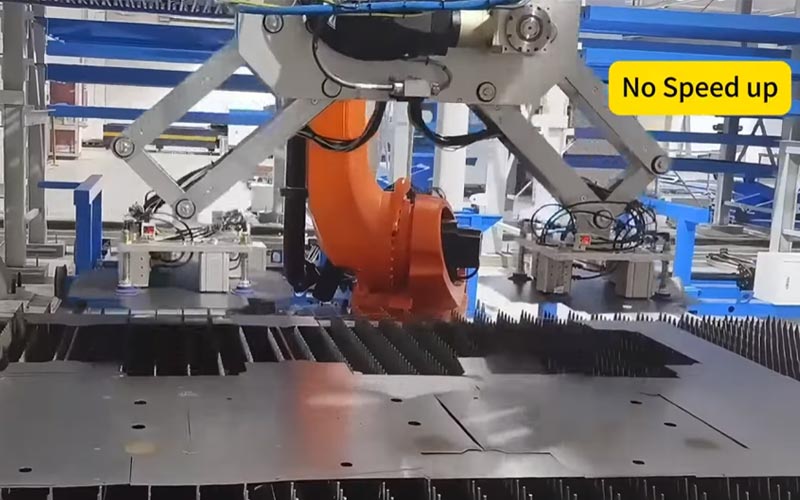

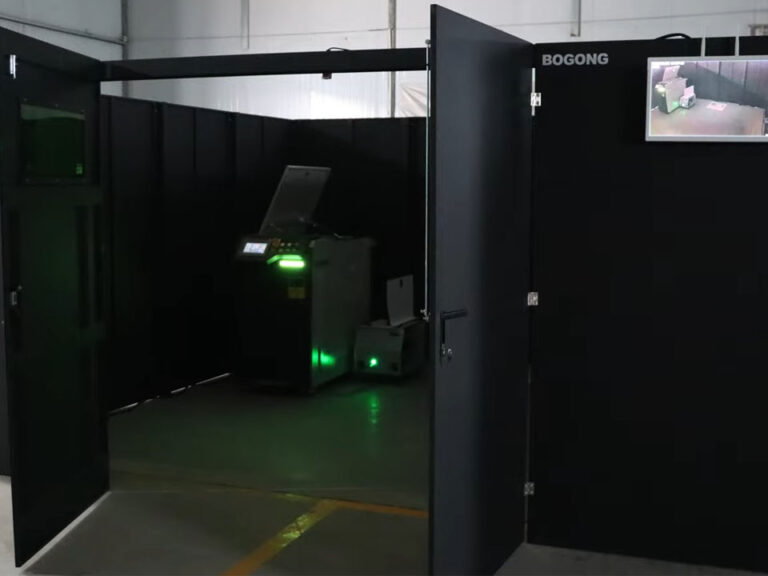

Hands-Off Material Handling: The End of Bottlenecks: The single biggest workflow killer in most shops is material handling. Manually loading a sheet, waiting for the cut, and then manually unloading parts is a massive time sink. Our Automatic Loading Laser Tube Cutting Machine completely automates this process. 3 A robotic system can feed raw materials, and once the cutting is complete, sort and stack the finished parts, allowing the machine to run continuously, even lights-out. See this seamless integration for yourself:

A Seamless Digital Thread: From Design to Delivery: Our systems create an unbroken chain of information from the initial design to the final product. Your engineers can send designs directly from their CAD/CAM software to the machine. Production managers can monitor job progress, track material usage, and generate efficiency reports from their desks. This “digital thread” provides unprecedented visibility and control over your entire operation.

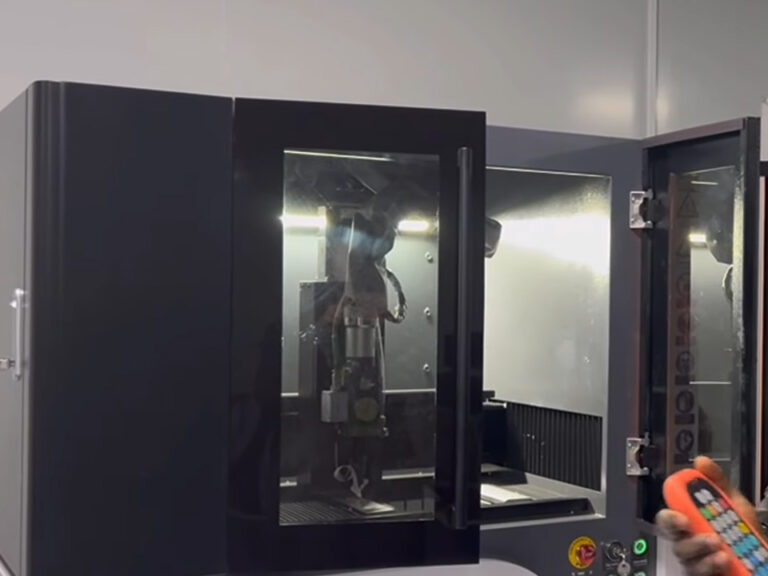

Predictive Maintenance: Preventing Downtime Before It Happens: Unplanned downtime is a profit killer. Our IoT-enabled machines monitor the health of critical components like the laser source and cutting head. The system can flag potential issues long before they cause a failure, allowing you to schedule maintenance during planned downtime. This proactive approach saves you from costly emergency repairs and lost production hours.

Beyond Speed: The Compounding Benefits of Laser Cutting Automation

The advantages of automation go far beyond just cutting faster. They create a compounding effect that transforms your entire business model.

Crush Your Operating Costs

Automation attacks your costs on three fronts. First, intelligent nesting software ensures you get the absolute maximum number of parts from every sheet, drastically reducing material waste. Second, modern fiber lasers are significantly more energy-efficient than older technologies. Third, by automating labor-intensive tasks, you can reallocate your skilled team members to higher-value jobs like quality assurance and machine programming, rather than just loading and unloading metal.

Achieve Flawless Quality, Every Time

Human error is a reality in any manual process. An automated system, however, delivers perfect consistency. The first part it cuts is identical to the ten-thousandth. Smart monitoring systems detect any deviation from the norm and correct it instantly. This level of quality control is essential for industries like aerospace and electronics, and it builds a reputation that wins long-term contracts.

Unlock Unprecedented Agility & Customization

In today’s market, “mass production” is often replaced by “mass customization.” Clients want small batches of highly specific parts. For a traditional shop, this is a nightmare of constant setup changes. For a BOGONG-powered smart factory, it’s business as usual. Our systems can switch from one job to the next with minimal setup time. A machine like our Laser Plate & Tube Combo Fiber Laser Cutting Machine offers incredible versatility, allowing you to process sheets and tubes with a single, flexible platform.

Scale Your Business on Demand

With an automated system, you can increase your output by 50% without needing to increase your headcount by 50%. This allows you to take on larger orders and grow your business without the massive overheads associated with scaling a manual operation. You can confidently bid on bigger projects, knowing your factory has the capacity to deliver.

A Day in the Life of a BOGONG-Powered Smart Factory

To make this concrete, let’s walk through a typical job:

- 2:00 AM: An order from a client in another time zone arrives via your online portal. The system automatically analyzes the CAD files.

- 2:05 AM: The software confirms the design is feasible and nests the parts onto a virtual sheet of 3mm stainless steel, optimizing for 94% material utilization. It schedules the job on Laser Cutter #3, which is due to finish its current run in 45 minutes.

- 2:50 AM: A robotic gantry retrieves the correct metal sheet from the automated storage tower and places it perfectly on the machine bed.

- 2:55 AM: The cutting begins. For parts that need weld preparation, the Bevel Fiber Laser Cutting Machine head automatically angles itself to create a perfect chamfer, eliminating a secondary processing step. 5

- 3:40 AM: The job is complete. A sorting arm with suction cups unloads the finished parts onto a pallet, while a separate system discards the skeleton. The system updates your inventory and notifies the shipping department.

- 3:45 AM: Laser Cutter #3 is already being loaded with the next job. There was zero idle time.

Your Transition to Smart Manufacturing: A Practical Guide

We understand the concerns. The initial investment can seem high, but we work with clients to demonstrate a clear ROI based on reductions in waste, labor, and downtime. There are cybersecurity risks, but we can help implement robust protocols to protect your data. Most importantly, there’s the skills gap. Our machines are designed with intuitive interfaces, and we provide comprehensive training to empower your team to manage and maintain your new digital systems.

What Does the Future Hold?

The evolution isn’t stopping. We’re moving towards AI that will not just optimize cuts but will manage the entire factory’s production schedule based on energy prices and supply chain deliveries. Edge computing will allow machines to process data and react even faster. This hyper-connectivity is the future, and investing in a BOGONG system today puts you on the right path for it.

Why Partner with BOGONG Laser? Experience, Technology, and Trust

Choosing a partner for this transformation is the most critical decision you’ll make.

- Global Experience, Local Support: With over 9,000 clients in 160+ countries, we have a global perspective on what works. We’ve seen the challenges and have developed proven solutions.

- A Complete Solution: We offer a full range of Laser Cutting Machine options and other laser technologies. 6 We are a single-source partner for cutting, welding, cleaning, and marking.

- Uncompromising Quality: Our commitment to quality is backed by the world’s leading certifications, including CE, FDA, and ISO9001. When you partner with BOGONG Laser, you are investing in reliability and peace of mind.

Frequently Asked Questions About Automated Laser Cutting

What is the real ROI I can expect from automation?

While it varies by application, clients often see a full return on investment in 18-24 months. This comes from reduced material waste (often by 10-20%), increased throughput (up to 50% or more), lower labor costs, and the ability to take on higher-margin, complex jobs.

How much training will my team need to operate these systems?

Our systems are designed with user-friendly interfaces. Typically, a few days of comprehensive training from our technicians is enough for your team to handle daily operations and routine maintenance. We focus on empowering your staff, not making them experts in robotics.

Can your systems integrate with my existing ERP or MES software?

Yes. Our software is designed for connectivity. We can work with your IT team to ensure our laser cutting systems can communicate with your existing factory management software, providing seamless data flow for scheduling, inventory, and reporting.

What kind of after-sales support do you offer?

We offer comprehensive support including installation, training, and a robust warranty. Our global network of technicians is available for on-site service, and we provide remote diagnostic support to resolve issues quickly and minimize downtime.

Should I choose a Fiber Laser or a CO2 Laser?

For most metal cutting applications, fiber lasers are the superior choice due to their speed, efficiency, and lower operating costs. However, CO2 Laser Cutters are still excellent for cutting organic materials like wood, acrylic, and leather. 7 We can help you analyze your specific needs to determine the best technology for you.

What is a beveling head and do I really need one?

A standard cutting head makes a 90-degree cut. A Bevel Fiber Laser Cutting Machine has a head that can tilt, allowing it to cut angled edges or chamfers. 8 If your parts require weld preparation, a beveling head is a game-changer, as it eliminates an entire secondary process, saving immense time and labor.

How much space do I need for an automated loading/unloading system?

The footprint varies depending on the level of automation. A simple pallet-to-pallet system requires less space than a full storage tower. We can design a layout that maximizes automation within your existing floor space.

What’s the thickest material a BOGONG fiber laser can cut?

Our high-power models, like the 6000W-40KW High Power Fiber Laser Metal Cutting Machine, can cleanly cut through significant thicknesses of mild steel, stainless steel, and aluminum—often exceeding 50mm or more, depending on the material and power.

Get Your Custom Automation Quote

Ready to see how automation can transform your business? Fill out the form below to have one of our automation specialists provide a free, no-obligation analysis of your needs and a custom quote.