-

Shunhua Road, orașul Jinan, Shandong

Laser Cutting in Jewelry and Luxury Goods Production

Jewelry & luxury laser cutting made practical: cleaner edges, steady fits, faster personalization. Explore fiber/CO₂ options from a global Manufacturer today.

Laser cutting is delicate

Laser cutting is non-contact. No blade deflection, no push marks on soft precious metals, no clamp scars on leather. That alone removes a big chunk of scrap. You set focus, manage heat, and get stable cuts for tiny parts, monograms, watch case windows, bracelet links, and leather tags. The machine doesn’t “fight” the part. It just follows code.

Clean edges, less post-polish

Heat-affected edge is the thing you fight. Keep pulses gentle, scan paths smart, and assist gas tidy, and you’ll cut thin precious metal with a small kerf and low burr. Less burr means less time on the buffing wheel. That’s not only nicer quality—it’s predictable labor. Your polishing bench quits being a bottleneck. Parts move.

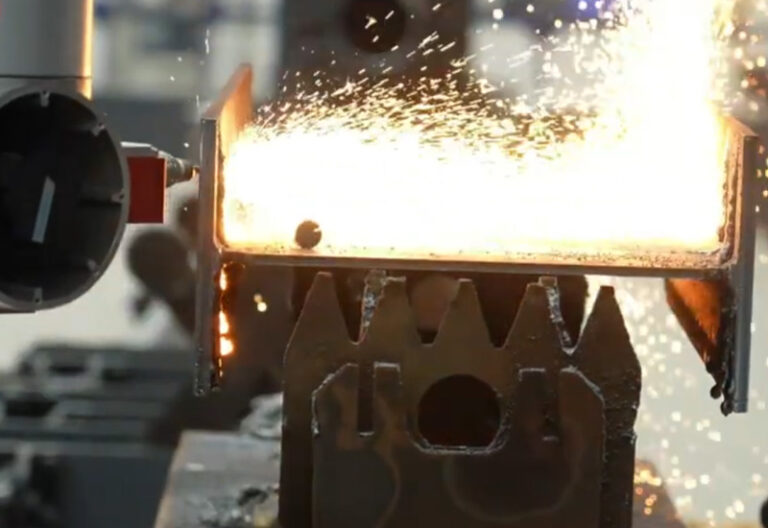

Watch below: a 3030 fiber laser cutting metal—see how crisp edges and stable paths look in a real setup.

BOGONG 3030 Fiber Laser Cutting Machine for Metal | Laser Cutter for Tiny Stainless Steel Jewelry

Some cases

Filigree and name charms

Tight inside corners and fragile bridges want low heat input plus a tight spot. Run multiple shallow passes instead of one heavy pass. Edges look crisp, and pieces don’t warp. You’ll notice fewer snaps when you lift small letters from the sheet.Watch cases and bracelets

You care about taper (wall straightness) and fit. Keep focus height honest across the path. Add a finishing pass with lower energy to “kiss” the walls smoother before you hit any finishing media. Seats well, looks premium.

- Leather personalization

Skin-friendly feel, high contrast, sharp curves. Control dwell so edges don’t get crunchy. In a boutique, add initials or dates right at the counter. Quick proof on scrap, then the real piece. It feels like craft, but it’s repeatable.

The quick Factory checklist

| Topic | What to check | Why it matters | How you adjust |

|---|---|---|---|

| Focus & beam spot | Verify on a small coupon first | Controls kerf and taper | Auto-focus or shim; fine-tune Z |

| Heat input | Keep per-pass energy modest | Reduces HAZ and burr | Increase speed; split into more passes |

| Assist gas | Dry, steady pressure | Clears melt; protects surface | Swap nozzle; keep lines clean |

| Fixturing | Rigid but gentle | Avoids micro-shift and scratches | Soft jaws, tape pads, dowel pins |

| Path strategy | Entry/exit off-part; final skim | Removes bite marks, polishes wall | Lead-ins/outs; low-energy finish pass |

| Cleanliness | Lens/nozzle clean | Keeps cut consistent all shift | Wipe schedule; spare optics ready |

Choose the right tool

For small jewelry pieces and mixed luxury tasks, the tool matters. Here are compact and combo rigs that map neatly to real work:

Cea mai mică mașină de tăiat cu laser cu fibră optică — For micro pendants, thin initials, inlays. Tight control in a small footprint near your polishing bench.

- Laser Plate & Tube Combo Fiber Laer Cutting Machine — If bracelets, bands, or jewelry tubing sit next to sheet parts, one bay for both reduces handling and dings.

- Mașină de tăiat cu gravură cu laser CO2 — Leather straps, suede pouches, wood displays, packaging inserts. Engrave and cut in one workflow for store-level personalization.

- 5050 Fiber Laser Cutting Machine — A compact sheet system when you need small metals by the assembly line. Easy placement. Clean fits.

Why laser beats traditional cutting in luxury

Less mechanical stress

No pushing the part, no bending thin bridges. Delicate details stay intact—good for filigree and thin uppercase letters that love to snap in mechanical setups.

Better geometry control

You can nudge kerf and taper by tweaking focus, speed, and pass count. Try doing that on a saw. You still measure, sure—but the path to “on-spec” is shorter and calmer.

Material versatility

Precious metals, stainless (watch parts), brass (findings), leather (straps/tags), even wood (displays). One platform across many materials. Less setup drama between jobs. The Factory breathes easier.

Words you may say

| Words | Translation | What we do |

|---|---|---|

| “Edges look burnt.” | Too much heat at the wall | Lower energy per pass; add speed; tune assist gas |

| “Holes not round.” | Thermal pull or rough entry | Add lead-in; recheck focus; two-pass finish |

| “Letters break.” | Thin bridges + heat + stress | More passes; better fixturing; tiny tabs for support |

| “Leather crispy.” | Over-burn at edges | Faster pass; slight defocus; better fume extraction |

| “Bracelet links don’t seat.” | Taper or burr problem | Final skim pass; gentle deburr; verify focus map |

Dialing in quality for jewelry

Kerf and taper

Keep kerf stable and taper small enough for snug fits—consistency wins. Use a “coupon board” at start of shift: two straights, one circle, one tight inside corner. If taper creeps, adjust focus or add a low-energy finish lap.

Burr and polish time

Burr is labor. Heavy burr? Back off energy density and give melt a cleaner exit with assist gas and a sharper nozzle. Many shops add one light skim pass to cut polish time. Net cycle drops and quality rises. Feels like cheating but it’s just process control.

Surface tone on precious metals

For visible edges (pendants showing the side), flatten striations with finer step-over or a cleanup pass. Small time, noticeable result. Your brand look gets “quietly premium.”

Process knobs vs. visible results

| Process knob | If you turn it this way… | You’ll likely see… | Use it when… |

|---|---|---|---|

| Pass count ↑ | Lower heat per pass | Smoother walls, less burr | Thin precious metal, tiny bridges |

| Speed ↑ (energy balanced) | Less dwell | Cleaner edges, lighter HAZ | Delicate shapes, name charms |

| Assist gas optimize | Cleaner evacuation | Lower discoloration, fewer beads | High-shine edges you plan to show |

| Focus fine-tune | Tight/true spot | Straighter walls, cleaner corners | Watch cases, bracelet grooves |

| Entry/exit paths | Off-part leads | No bite marks at start/stop | Visible edges and inside cutouts |

| Final skim pass | Gentle clean | Reduced hand-polish time | Premium faces, tight deadlines |

Why BOGONG LASER maps well

You want a Manufacturer that ships globally, supports many languages, and understands luxury’s obsession with finish. BOGONG LASER covers fiber and CO₂ cutters with major certifications (CE, ISO9001, SGS, FDA). The range spans micro workstations, compact sheet systems, and plate-tube combos—so you can phase in the process, not rip-and-replace. Parameter libraries, clean optics habits, simple fixturing—this is where our support team lives.

Final thought

Laser cutting is repeatability. Keep heat gentle, optics clean, and fixtures kind. The rest follows. If you want micro detail, choose a compact fiber workstation and write a calm recipe. If you need leather and packaging plus engraving, go CO₂. If your bracelets or case frames mix plate and tube, consider a combo bay. And please—check focus every shift.

Welcome to fill the contact bogong form. We’ll reply with practical advice.