-

Shunhua Road, Jinan City, Shandong

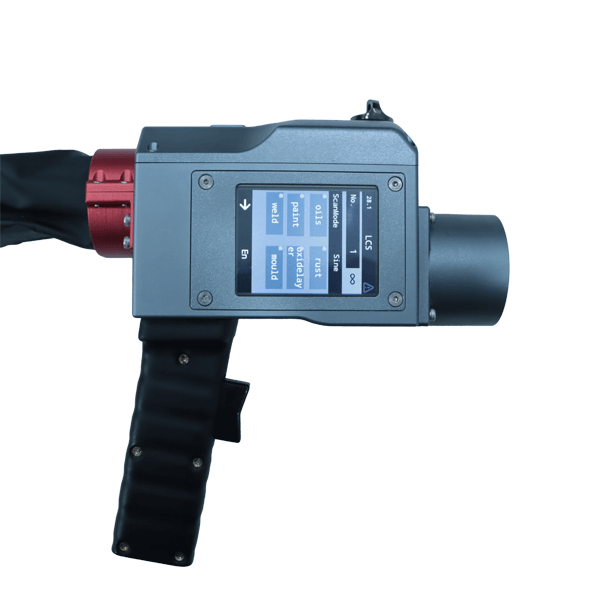

500W Pulse Laser Cleaning Machine

500W Pulse Laser Cleaning Machine

The 500W pulse laser cleaning machine is equipped with a JPT laser source that delivers a maximum pulse energy of 2mJ, 5mJ, 15mJ or 50mJ. This generates a laser beam with gentle light output, ensuring that undamaged surface after cleaning. It is ideal for a range of applications, including manufacturing, aerospace, automotive, marine vessels, medical equipment, and molds.

- 100 Sets / Month Waiting for Sale In Stock

- 2 Years Limited Warranty for Entire Machine

- 3-5 days prepare laser machine, 3-7days transport.

- Online (PayPal) & Offline (T/T, Debit & Credit Cards)

- Laser Type: MOPA Laser

Laser Power: 500W

Output Range (If Adjustable): 0-100%

Pulse Formation: MOPA (Quality Factor)

Laser Generator: JPT/MAX/Raycus

Fiber Length: 5m

Cooling Type: Water Cooling, BOGONG also provide you air cooling laser machine, you can find it in below article

After Sale: 2 Years

There have 16 Supported Languages for your selection.

The pulse laser cleaning machine currently supports multiple languages, including English, Russian, Japanese, Spanish, German, Korean, French, Polish, and 16 others.

You can easily switch between these languages on the machine’s interface. If you need additional languages, we also offer customized language services to meet your needs.

Feature of 500W Pulse Laser Cleaning Machine

- High-Power 500W Pulsed Laser Technology: Delivers powerful energy pulses that quickly and effectively remove rust, oil, and residues.

- Fine Cleaning Capabilities: Provides precise cleaning results, making it ideal for applications that require meticulous attention.

- High Efficiency: Drastically cuts down cleaning time compared to traditional methods, enhancing productivity and reducing operational costs.

- Non-Destructive Cleaning: Employs a non-contact and non-abrasive approach that protects the underlying material and eliminates the risk of damage.

- User-Friendly Operation: Features an intuitive interface and ergonomic design for easy handling, requiring minimal training.

Benefits:

- Superior Cleaning Performance: Achieve a high level of cleanliness essential for optimal performance in various industrial settings.

- Cost-Effective Solution: Reduces the need for consumables like chemicals and abrasives, resulting in long-term savings.

- Environmentally Friendly: Generates minimal waste and eliminates harmful chemicals, contributing to a safer and greener workplace.

- Versatile Applications: Effective for cleaning a wide range of materials, including metals and composites, across different industries.

Applications:

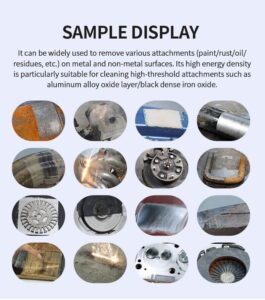

- Rust Removal: Effectively eliminates corrosion from metal surfaces, restoring them to their original condition without using abrasive methods.

- Oil and Grease Cleaning: Removes oils, lubricants, and other contaminants that can affect performance or adhesion in manufacturing processes.

- Surface Preparation: Prepares surfaces for painting, coating, or welding by ensuring they are clean and free of contaminants.

- Maintenance and Restoration: Perfect for cleaning machinery, tools, and equipment, extending their lifespan and maintaining peak functionality.

How to Choose the Right Pulse Laser Cleaning Machine

Choosing the right pulse laser cleaning machine will be important for your business, how to make sure the machine meets your specific needs. Here’s a guide to help you make an informed decision:

- Material Compatibility: Determine the types of materials you plan to cleaning (e.g., rust, painting, on metal wood, acrylic, etc). Ensure that the machine you choose can handle these materials effectively.

- Laser Type: Different laser types 2mj, 5mj,15mj, 50mj, different laser different result.

- Work Area Size: Assess the size of the cleaning area based on the projects you plan to undertake. Ensure the machine has an adequate working area for your items. choose Right F-theta lens, pls ask our sales about this.

- Ease of Use: Look for machines with user-friendly software that allows for easy design and operation.

- Customer Support and Warranty: Research the manufacturer’s support options and warranty offered. Reliable customer service can be crucial for troubleshooting and maintenance.

1. Deposit and Balance: A 30% T/T deposit is required in advance, with the balance due before shipment.

2. Alibaba Trade Assurance: Payments can be processed through Alibaba Trade Assurance.

FAQs for 500W Pulse laser cleaning machine

What Is the Packaging for the 500w laser cleaner?

Our machines are packaged in a three-layer setup. The outer layer consists of a wooden crate, the middle layer features foam padding to protect against shaking, and the inner layer includes a thick plastic bag for waterproofing.

Will the Package Be Damaged During Transportation?

We meticulously design our packaging to address all potential damage factors, and our shipping agents are experienced in safe transportation. We have successfully exported to 180 countries, so you can rest assured that your parcel will arrive in excellent condition.[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_toggle title=”How Much Is The Price of A 500W Pulse Laser Cleaning Machine?” style=”arrow” css=””]The price of a 500W Pulse Laser Cleaning Machine varies depending on the Laser Source, Generally, you can expect to pay between $16,000 and $25,000. It’s best to contact suppliers directly for a tailored quote based on your specific needs.[/vc_toggle][/vc_column][/vc_row][vc_row][vc_column][vc_toggle title=”What Is The Maintenance And Operating Cost of A 500W Pulse Laser Cleaning Machine?” style=”arrow” css=””]The maintenance and operating costs of a 500W Pulse Laser Cleaning Machine most include electricity consumption, routine maintenance, and occasional replacement parts. On average, the electricity cost may range from depending on usage intensity. Routine maintenance, such as lens cleaning and system inspections, can cost around $20 to $200 per year.[/vc_toggle][/vc_column][/vc_row][vc_row][vc_column][vc_toggle title=”What Types of Surfaces Can A 500W Pulse Laser Cleaning Machine Effectively Clean?” style=”arrow” css=””]A 500W Pulse Laser Cleaning Machine can effectively clean a wide variety of surfaces, including:

– Metal surfaces such as steel, aluminum, and cast iron

– Rust, oil, grease, and paint coatings

– Oxide layers and surface contaminants

– Mold release agents and residues

It is suitable for cleaning complex geometries, delicate surfaces, and hard-to-reach areas without causing damage. However, the effectiveness may vary depending on the material and the type of contamination.[/vc_toggle][/vc_column][/vc_row][vc_row][vc_column][vc_toggle title=”What Kind of Maintenance Does The 500W Pulse Laser Cleaning Machine Need?” style=”arrow” css=””]The 500W Pulse Laser Cleaning Machine requires routine maintenance to ensure optimal performance and longevity. Typical maintenance tasks include:

1. Lens and Nozzle Cleaning: Regularly clean and inspect the lens and nozzles to prevent dust, dirt, or residue buildup that can affect laser quality.

2. Cooling System Check:Ensure the cooling system (water or air cooling) is functioning properly, with regular checks for leaks or blockages.

3. Laser Source Inspection: Periodically inspect the laser source for signs of wear and follow manufacturer guidelines for maintenance or replacement if needed.

4. Electrical Components: Check wiring, connectors, and power supplies for any signs of damage or wear.

6. Cleaning External Parts: Wipe down the exterior and ventilation areas to prevent dust accumulation.

Performing these maintenance tasks regularly can help maintain consistent cleaning performance and prevent costly repairs.

The 500W Pulse Laser Cleaning Machine typically uses a water cooling system to manage heat generated during operation. This method involves circulating high-quality, deionized water through the laser source and other critical components to efficiently dissipate heat and maintain stable performance. Proper maintenance of the cooling system, such as regular water quality checks and leaks inspection, is essential for reliable operation.

The cleaning area of a 500W Pulse Laser Cleaning Machine typically ranges from approximately 100 mm x 100 mm to 200 mm x 200 mm, depending on the specific model and configuration. This allows efficient cleaning of small to medium-sized surface areas with precision. For larger surfaces, the machine can often be moved or combined with scanning systems to cover a broader area.

|