-

Shunhua Road, Jinan City, Shandong

Laser Cutting Machine Application

Laser Cutting Machine Application

Laser Cutting Machine Application

Laser Cutting Machine Product Recommendation

CO₂ laser cutting machine: suitable for non-metallic materials such as acrylic, leather, paper and wood.

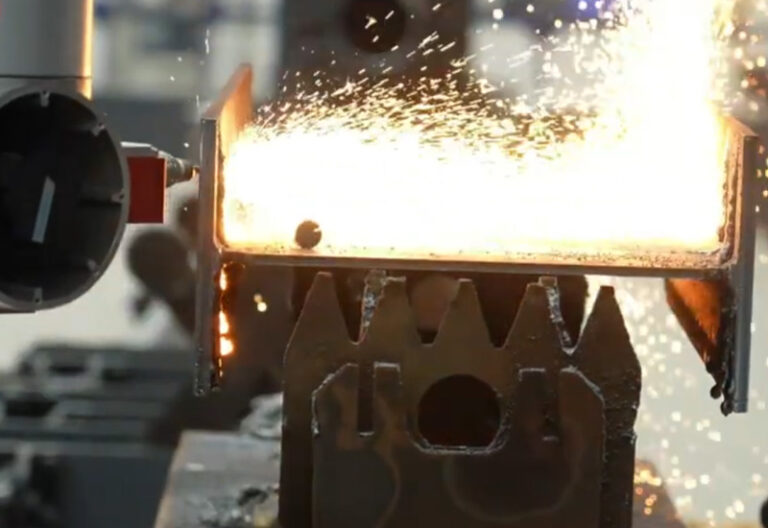

Fiber laser cutting machine: suitable for metal materials such as stainless steel, aluminum and metal plates.

Ultra-short pulse laser cutting machine: suitable for glass and precision micro-machining applications.

Best 200W Pulse Laser Cleaning Machine

Mini Split Fiber Laser Engraving Machine

CW Laser Cleaning Machine

Fiber Laser Engraving Cutting Machine For Metal Jewelry

UV Laser Marking Machine

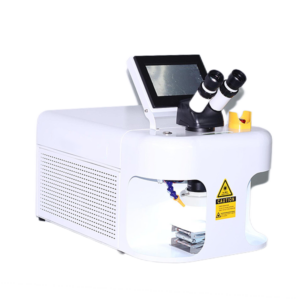

150W Jewelry Laser Welding Machine

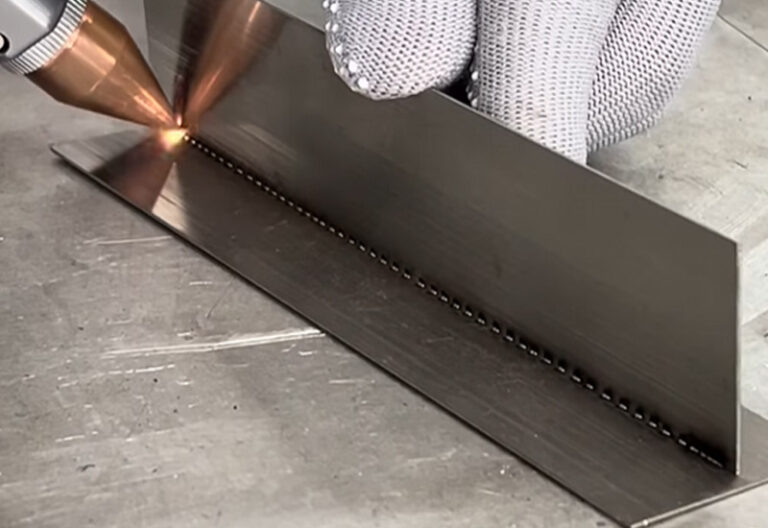

Air-Cooling Handheld Laser Welding Machine For Sale

Trolley Case type Laser Cleaning Machine

3 in 1 Handheld Laser Welder

FAQs About Laser Cutting Machines

Contact Us to Help You Choose the Laser Cutting Machine that Suits You:

BOGONG LASER® Blog – Laser Cutting Machine Application and Industry Information

CO2 Laser Cutting Machine for Foam Tool Inserts

CO2 laser cutting for foam tool inserts: improve tool control, reduce waste, and upgrade your workshop look with BOGONG Laser CNC solutions for global industrial users.

Handheld Laser Welder for Display Sign Frames

Handheld Laser Welding Machine for display sign frames: cut grinding, reduce distortion and boost finish quality with BOGONG LASER® welding solutions for signage.

Laser Metal Cutting Machine for Construction Formwork

Laser Metal Cutting Machine for construction formwork. Cut cleaner panels, reduce scrap, speed delivery. BOGONG LASER helps factories upgrade cutting for real site demands.

Fiber Laser Cutting Machine for Kitchen Exhaust Hoods

Fiber Laser Cutting Machine for kitchen exhaust hoods: improve cut quality, airflow parts and lead time with BOGONG LASER, a global laser cutting machine manufacturer.

Fiber Laser Marking Machine for Bearing Batch Codes

Fiber laser marking for bearing batch codes. Learn how BOGONG Laser machines boost traceability, fight counterfeits and cut rework for global bearing makers.

Laser Engraving Machine for Tumbler Customization

Looking for stable tumbler branding? Discover how BOGONG Laser Engraving Machine solutions help factories customize cups in-house and grow B2B orders.