-

Shunhua Yolu, Jinan Şehri, Shandong

Laser Cleaning for Food Processing Equipment

Boost food-plant uptime and sanitation with BOGONG Laser’s eco-friendly, chemical-free laser cleaning machines. Fast, precise, and ISO-certified for any line.

Laser cleaning for food processing equipment is a method that makes use of concentrated laser beam of lights to eliminate contaminants like oil, rust, and food residue from surfaces.

Why Laser Cleaning Matters in Food Processing Contexts

Food plants live and breathe on hygiene. A little leftover residue can hide salmonella or listeria and cost you big. Wet-chemical spray stations drainage, rough techniques gnaw at steel, and disassembly eats hours. Laser cleaning utilizes a securely focused light beam– either pulsed or continuous-wave– to ablate just the crud.

Core Advantages of Laser Cleaning Machines

High-Speed Cleaning Maximizes Throughput

Modern galvo-scanner heads clean dramatically faster than typical chemical spray systems—many times faster. You clear conveyor belts, molds, and grates in a flash, boosting overall equipment effectiveness.

Micron-Level Precision Protects Equipment

You tune beam spot and dwell so precisely that only the unwanted layer is removed. You don’t erode polished hopper walls or thin-walled frames. That selectivity keeps capital gear in prime shape and helps you avoid costly replacements.

No-Contact Operation Cuts Wear & Tear

Because the laser never touches the metal, you avoid abrasive rebound and vibration. Belts, bearings, and seals see less stress. The result is fewer breakdowns and longer service intervals—an easy win for maintenance budgets.

No Waste, No Chemicals

Laser cleaning uses no water and no solvents. Removed debris is captured by the fume-extraction system. You eliminate chemical-sludge disposal and meet recognized environmental management standards without adding waste lines.

Better Surface Prep for Coatings

With no abrasion, base steel thickness and surface finish stay intact. Coatings and anti-stick treatments adhere better, which quietly lifts final product quality.

On that note, let’s see laser cleaning in action.

China 100W 200W Handheld Laser Cleaning Machine for Rust Paint Oil removing from Metal and Ground

Safety, fume extraction, and good housekeeping

Capture fumes at the source with the right filters for fine particulate and odors.

Shield nearby gaskets, sensors, and cables; block reflections on polished stainless.

Cover open product zones and manage airflow away from food contact areas.

Train operators on interlocks, beam awareness, lens care, and filter handling.

Hygiene, validation, and audit readiness

Treat laser cleaning like any other sanitation step inside your HACCP and SSOP programs.

Define soils: fat, protein, sugar, scale, light oxidation—each gets a tailored pass strategy.

Build recipes: pair surface type (stainless, aluminum, food-grade plastics) with residue and a saved scan pattern.

Verify results: visual inspection plus ATP swabs or contact plates where appropriate.

Record it: before/after photos, area cleaned, operator, extraction maintenance, and any corrective actions.

Close the loop: include laser steps in SSOPs and link to CCP/CPs if applicable.

Comparison at a glance

| Temizleme Yöntemi | Hız | Water Use | Chemicals | Downtime |

|---|---|---|---|---|

| Lazer Temizleme Makineleri | Highest | Hiçbiri | Hiçbiri | Shortest |

| Wet-Chemical Spray | Lowest | Very high | Significant | Longest |

| Abrasive Blasting | Yüksek | Hiçbiri | Hiçbiri | Long |

| Dry Ice Blasting | Orta düzeyde | Hiçbiri | Hiçbiri | Short |

Laser cleaning eliminates water and chemicals while reducing time off the line.

Where it shines

Meat‑Cutting Conveyor Revival

A pork line battled baked‑on blood and fat in roller bearings. They deployed a 200 W Pulse Laser Cleaning Machine to blast away residues without disassembly—getting the line back online within minutes.

Rust Removal on Veggie Wash Panels

Acidic sprays corroded leafy‑green sprayers until they used a CW Fiber Lazer Temizleme Makinesi, stripping rust without pitting the stainless and getting operations back up quickly.

Dairy Pasteurizer Piping Rehab

Tartar lodged inside CIP loops forced full teardown—until they switched to a 1,000 W Pulse Laser Cleaning Machine. Crews scanned the pipes in place, slashing rebuild time significantly.

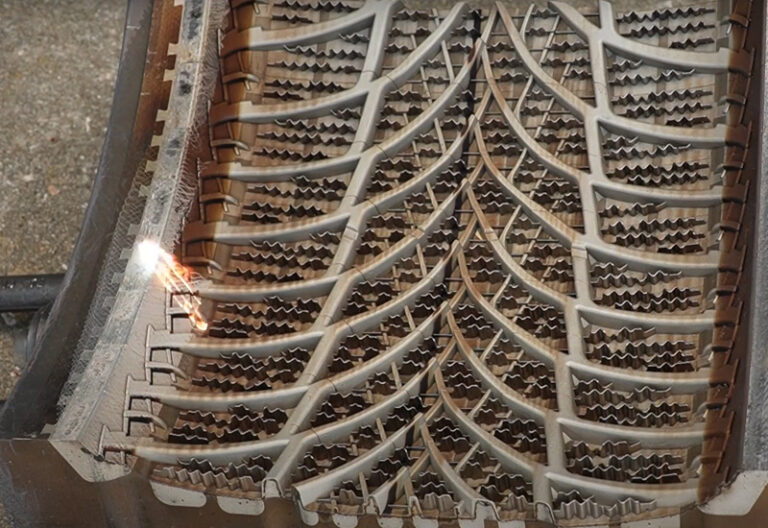

Bakery Mold Refurbishment

Sugar crust wrecked mold detail on aluminum trays. A Arabalı Kasa Tipi Lazer Temizleme Makinesi rolled right into the bake house and restored molds in batches.

Sonuç

Switching to laser cleaning in food processing slashes downtime, cuts waste, and locks in top-tier hygiene. Whether you run meat, dairy, produce, or baked goods, BOGONG Laser’s CE-certified, ISO-compliant rigs deliver the speed and precision you need. Reach out to find your perfect match and keep your plant spotless, safe, and humming.