For welding metals like aluminum, steel, copper, and various alloys, laser welding machines are the perfect choice with high speed and precision. Whether you’re looking for a manual or automated solution, our team of laser experts is ready to assist you in seamlessly integrating it into your production line.

Additionally, our solutions are valuable for research and development, supporting both process improvement and product development.

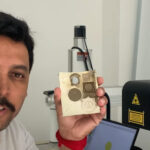

HAND-HELD FIBRE CONTINUOUS LASER WELDING MACHINES

Product Description

The BOGONG Handheld laser welding machines with feature of lexible and user-friendly. it can weld stainless steel, mild steel, carbon steel, aluminum alloy, and other materials, these machines deliver smooth and precise welding results.

Each system is complete with all necessary components, including advanced fiber lasers, a laser control system, a safety light extraction system, a water cooling system, and a handheld welding head.

Compact and portable, Bogong Handheld Laser Welder is perfect for businesses with limited space, maximizing the use of this practical machine. It’s available in three power options: 1500w 2000w 3000w

Laser welding outperforms traditional methods such as ultrasonic bonding, TIG welding, and resistance welding. With laser weld monitoring devices, detecting and correcting defects in real-time is straightforward and efficient.

JEWELRY LASER WELDING MACHINES

Product Description

The Jewelry Laser Welding Machine is a spot welder specifically designed for gold, silver, and stainless steel. It offers precise and controlled spot welding, making it perfect for delicate jewelry pieces. Users can easily position their workpieces under the laser head, whether they are repairing a broken item or crafting a new creation. This machine is a valuable asset for any jeweler’s toolkit.

The laser beam generates intense heat that melts the metal, creating a strong and durable weld. What makes laser welding especially valuable for jewelry making is its ability to provide the precision needed to join delicate metals and intricate designs seamlessly.

ROBOT LASER WELDING MACHINE

Automatic Welding Solution— Aims to deliver intelligent digital workshop solutions tailored to customer needs. We provide comprehensive industrial automation solutions, guiding you from the initial concept to implementation in your workshop.

Manufacturers use lasers and robotics for their speed and precision, making it common for these two technologies to work together on production lines for laser welding.

Instead, higher speeds can be achieved through remote laser welding, where robots quickly clamp each weld in place. This approach is known as robot-assisted laser welding.

Metal Mould Repair Laser Welder

The laser mold repair welding machine efficiently and precisely repairs pores, slag holes, and shrinkage defects that occur during the casting process.

Mold repair involves fixing damages to molds that have been used in industrial applications. This process can include making modifications and adjustments to the shape, size, or overall condition of the mold cavity. Repairing a mold can be intricate and may require various methods, such as grinding, machining, and welding. Sometimes, a combination of these techniques is necessary to bring the tool back to its original condition.

FAQ Laser Welding Machine

Does laser welding really work?

Yes, laser welding is a precise and efficient method that creates strong welds with minimal distortion.

How much does laser welding cost?

The price of a laser welder can vary based on the brand, model, and features. Entry-level machines typically range from $3,500 to $10,000, while premium models can exceed $20,000.

Is laser welding as strong as MIG welding?

Laser welding can create stronger welds than MIG welding because it penetrates materials more deeply and utilizes heat more efficiently.

What are the disadvantages of laser welding?

Laser welding produces less heat and a smaller heat-affected zone (HAZ) compared to traditional welding methods.

Does laser welding need gas?

Nitrogen (N2), Argon (Ar), and Helium (He) are all suitable options

GET IN TOUCH

CONTACT BOGONG

Whether you are interested in our Laser Welding Machine our team at Bogong Laser is here to provide professional consultation and tailored solutions. Get in touch today to discuss your specific laser machine requirements and receive expert support from Bogong Laser.