LASER CUTTING MACHINE

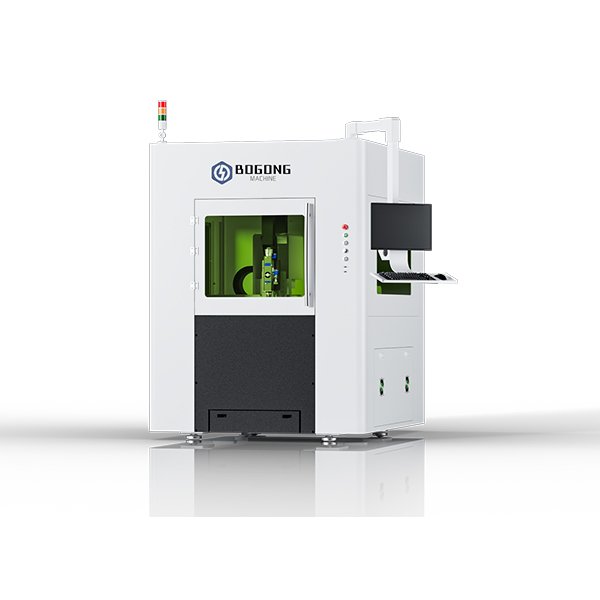

BOGONG LASER offers range of Laser Cutting Machine in Fiber, CO2, Picosecond formats, each of these technologies delivers exceptional speed and precision in cutting tasks.

These machines utilize powerful lasers to cut through a wide range of materials, including wood, metal, plastic, and fabric, with remarkable accuracy and minimal waste. Among the most popular types of laser cutting machines are fiber laser cutters and CO2 laser cutters. Fiber laser cutters are known for their speed and efficiency in cutting metals, making them ideal for industrial applications. In contrast, CO2 laser cutters excel in cutting non-metal materials such as wood, acrylic, and textiles, making them a favorite among DIY enthusiasts and small businesses.

Whether you’re a manufacturer looking for high productivity or a hobbyist seeking creativity, laser cutting machines offer versatile solutions to meet diverse cutting needs. BOGONG will provide you high quality Fiber, CO2 and Pico-second laser cutting machines, ensures that there’s a perfect solution for all your cutting needs. Our commitment to providing top-tier technology means that you can trust BOGONG Lasers for efficiency and quality in every cutting project.

A fiber laser cutter is an automated machine that uses a CNC controller guide a 1064nm laser for cutting metal shapes from plates, pipes, and rods based on CAD designs. It’s precise and versatile, suitable for sheet metal and tube cutting, capable of handling thicknesses from 1 mm to 200 mm. With a robotic arm, it creates custom 3D designs without damaging the substrate, operating at speeds over 120 meters per minute. It works with both hard and reflective metals, making it popular for various applications. fiber laser cutting source from 1500w to 100000w.

BOGONG metal sheet cutting machine which has passed the CE, FDA, etc. For more information about fiber laser cutter, please kindly send an inquiry, and sales manager will send you technical solutions right away

A CO2 laser cutter is an automated tool uses a focusing lens to focus the CO2 laser beam onto the surface of the material to melt it, It effectively etches and cuts various nonmetals and metalloids, offering precision on materials from soft fabrics to rigid plastics. This includes tasks like creating simple acrylic letters, intricate 3D wood puzzles, and fine engravings on glass, stone, crystal, and ceramics.

User-friendly and environmentally friendly, it’s ideal for both beginners and experienced users. At BOGONG, you can find a variety of CO2 laser models suited for any application, whether hobbyist or industrial, with options ranging from compact cutters to large 4×8 cutting tables. Prices range from $2,500 to $30,000, catering to different budgets.

Find Your Perfect Laser Cutter

PICK YOUR FIRST LASER CUTTING MACHINE FOR HOME & INDUSTRIAL USE

You don’t need to own a large company to invest in your next laser cutter. In recent years, many affordable options have emerged, allowing you to find a cutting solution that fits your budget. However, it’s crucial to be cautious with your purchase since quality is paramount. Look for a precise, reliable machine with high-quality components and ensure you receive proper training and support.

Consider your specific needs and budget when choosing an automatic cutting tool and select the one that aligns best with your requirements. With the right smart cutting system, you can meet your production goals without overspending. Moreover, with the ongoing advancements in Industry 4.0 and artificial intelligence, laser cutting technology is increasingly being integrated with industrial robots, enhancing cutting speed, thickness, accuracy, and quality.

What Is A Laser Cutting Machine?

A laser cutting machine is an automated device that adopt a CNC controller and software to cut through metals, metalloids, and nonmetals with a CO2 or FIBER laser beam. It can create custom shapes, contours, and holes from sheets and profiles, making personalized parts such as signs, tags, decorations, crafts, gifts, jewelry, lamps, and puzzles for both hobby and industrial applications.

This system employs a laser beam along with a smart digital cutting mechanism to produce patterns on various materials, including metals (like steel, copper, and aluminum), acrylic, rubber, wood, MDF, plastic, leather, paper, foam, and textiles. A typical laser kit includes a machine base, CNC controller, generator, power supply, laser tube, lens, mirror, water chiller, motors, gas cylinder, air compressor, and software.

A laser cutting system is an integrated collection of parts designed for precision cutting across diverse applications, including industrial manufacturing, commercial use, and small businesses. It offers more flexibility compared to manual and mechanical tools, capable of handling various materials in different thicknesses with limitless shape possibilities. It is quick to program, allowing for easy modifications throughout the manufacturing process at minimal cost and time. This method results in high precision, excellent trimming quality, and no deformation, making it an ideal solution for modular and automated production.

How Does A Laser Beam Cutting Machine Work?

A laser beam is a concentrated light produced by the transition of atoms, differing from regular light by its pure color, minimal divergence, intense brightness, and high coherence.

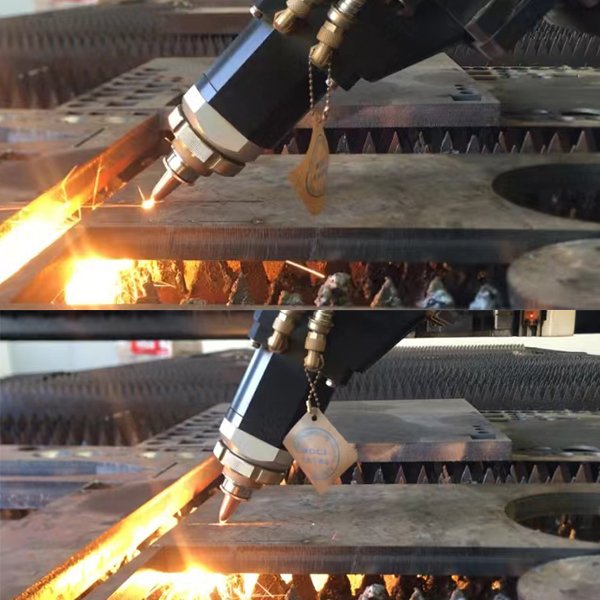

The cutting process involves using a focused light beam with high power and density to melt and vaporize materials like metal, wood, acrylic, plastic, fabric, and leather, resulting in precise cuts.

The CNC controller directs the generator to create a high-frequency beam, which travels through an optical path and is focused through lenses to produce a small, intense light spot on the material’s surface. This high-energy beam reaches temperatures that melt or vaporize the material almost instantly, creating small holes with each pulse. As the CNC system moves the cutting head relative to the substrate, it follows the design file to shape the material.

The cutting speed, power, and gas pressure are controlled by the CNC system, while auxiliary gas blows away any residue created during the cutting process. Finally, the beam’s high power density melts or boils the material at the cutting point, with high-pressure gas removing the molten or vaporized material to achieve the desired cuts. The required power level varies based on the thickness of the material, with higher power suited for thicker cuts, so it’s important to select the right specifications for your needs.

if you are looking for a reliable manufacturer and brand with affordable price, BOGONG can be an excellent place to rely your trust on.

GET IN TOUCH

CONTACT BOGONG

Whether you are interested in our Laser Cutting Machines our team at Bogong Laser is here to provide professional consultation and tailored solutions. Get in touch today to discuss your specific laser machine requirements and receive expert support from Bogong Laser.