-

Strada Shunhua, città di Jinan, Shandong

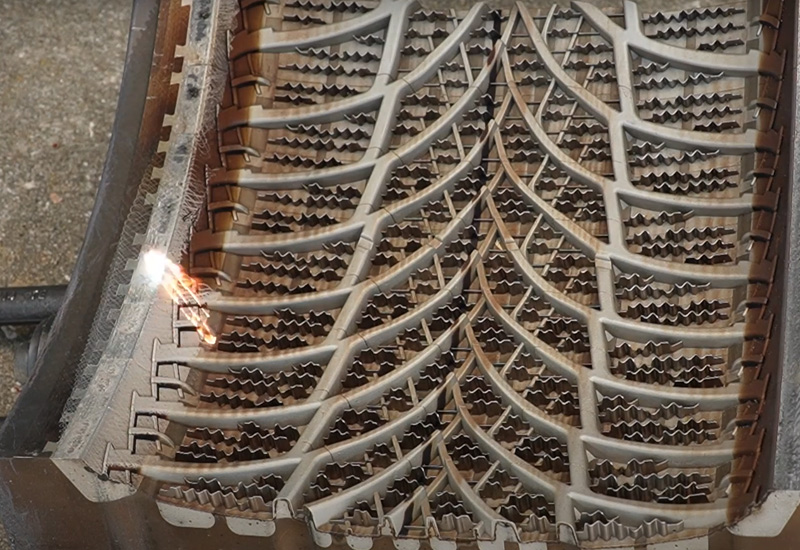

Pulse Laser Cleaning Machine for Injection Mold Maintenance

Pulsed laser cleaning for injection molds: protect texture/plating, cut downtime, no media mess. See BOGONG LASER solutions for real factory workflows.

why molds foul (and why you feel it on the line)

Injection molds don’t stay pristine. Release agents, polymer additives, off-gassing, and a bit of oxidation stack up fast. You see it in flash, gloss drift, short shots, and mystery streaks. Pulling the tool for a bath kills your OEE, and blasting can chew micro-texture. So teams look for a Laser Cleaning Machine that strips residue without chewing steel. That’s where pulsed laser cleaning earns its keep.

How pulsed laser cleaning actually works

Short bursts (pulses) of light hit the residue. The layer heats crazy fast and ejects—ablation, desorption, tiny shock. The base metal? Heat doesn’t soak in much because the pulse is short. Result: deposits go, texture stays. No media, no slurry, less rework. And yes, you still want fume extraction and proper guarding.

Where it lands in shops

Textured cavities & fine engraving: You want the “orange peel” or shot-peen look untouched. Pulsed lasers can nibble residue without rounding peaks.

Chrome-plated cores: Media blasting can undercut plating over time. Pulsed beams, tuned right, keep the surface intact.

Vent lines & parting faces: Localized burn-on and plate-out? A quick pass between runs beats pulling the tool.

Grease/oil films around slides: Zero media means zero grit trapped later.

Why go pulsed vs. other methods

Precision beats speed

On big flat plates, blasting looks faster. But for high-detail cavities, the pulsed beam is predictable, repeatable, media-free, and kinder to textures and plating. Also, less cleanup.

Process control you can teach and repeat

Pulsed cleaning is parameter-driven: pulse energy, frequency, scan speed, spot overlap. You can write a SOP, lock a recipe, and hand it to night shift. That’s why Macchina per la pulizia laser Produttore systems get adopted: they make precision repeatable, not artisanal.

What the shop actually cares about: time, finish, risk

| What you care about | Pulsed Laser Cleaning | Dry-Ice / Bead / Soda | Solvent / Ultrasonic |

|---|---|---|---|

| Finish safety (texture, plating) | High, if tuned; non-contact | Medium; can round texture edges | Medium; chemistry exposure |

| Media & waste | None (just fume capture) | Yes (consumables + containment) | Yes (chemicals, disposal) |

| Speed on large areas | Moderato | Veloce | Moderato |

| Accuracy in tiny features | Very high | Medio | Medio |

| Setup & ramp | Recipe-based; trainable | Simple but variable | Bath prep, dwell |

| Line disruption | Low; in-press touch-ups possible | Medium; masking & cleanup | High; tool off-line |

Field snapshots

Chrome-plated insert with plate-out in tight engravings. Blasting couldn’t reach. Pulsed cleaning cleared corners; plating stayed shiny. Downtime cut because no masking and no rinse.

Vent burn around parting lines. A low-energy sweep between runs kept vents clear enough that the tool didn’t leave the press all week. Scrap trend dropped; QA quit flagging “streaks.”

Micro-texture bumping gloss variance. Gentle passes restored surface without rounding. Customer didn’t notice any texture shift; production did notice the schedule breathing again.

Quick decision guide

| If this describes your scenario… | Then lean toward… | Perché |

|---|---|---|

| Lots of tiny features, engraving, texture you must protect | Pulsed Laser Cleaning | Recipe control; zero media; finish safety |

| Massive plates, geometry simple, time is everything | Dry-ice / bead | Coverage speed over precision |

| You want in-press touch-ups, zero chemicals | Pulsed Laser Cleaning | Local passes, no bath |

| Heavy, baked-on film that laughs at pellets | Pulsed Laser Cleaning | Localized energy density, controllable |

| After-blast film or complex masking headaches | Pulsed Laser Cleaning | No taping, no grit in slides |

“Black talk” you may hear

“Don’t gloss the peaks.” Keep texture crisp; if peak tips dull, you’re hot.

“Stay out of the vents.” Actually: touch them lightly. One low-energy pass, not a dig.

“No heat soak on ribs.” Thin features distort quick; shorten dwell, increase scan speed.

“Don’t chase brown.” If residue discolors but doesn’t lift, don’t crank power first—check focus and overlap.

“Keep your recipe tight.” Lock parameters per surface class (polished, EDM, plated). Label them.

Choose the right BOGONG LASER products for different Scenario

Macchina di pulizia laser a impulsi 1000W — for deep, stubborn fouling where you still need finesse.

Macchina di pulizia laser a impulsi da 500W — balanced choice for daily mold TLC and on-press touch-ups.

Macchina di pulizia laser a impulsi 200W — light, precise, super friendly for tight cavities and engraving.

Macchina di pulizia laser a impulsi con laser Raycus Max JPT — flexible sources for different residue behaviors and surface classes.

When CW cleaning makes sense (and when to keep it pulsed)

Continuous-wave (CW) cleaning moves fast on broad, simple geometry. Think bulk de-rust or paint strip on fixtures, big plates, frames—then switch to pulsed for the sensitive, textured, or plated bits. If you need that combo workflow, BOGONG also offers Macchina per la pulizia del laser a fibra CW so you can match tool to task.

Commercial value

If your scrap is tied to finish drift and your downtime is tied to bath/solvent cycles, pulsed cleaning cuts both. No media logistics, less masking, fewer re-polish surprises. Teams standardize on a small set of recipes, store them per tool/surface, and get predictable turnarounds.

And yes, this is where BOGONG LASER® helps as a Laser Cleaning Machine Factory and Laser Cleaning Machine Manufacturer:

Broad line (pulsed + CW) so you can mix speed and finesse.

OEM/ODM support for oddball fixtures and guarding.

Global install base across automotive, electronics, packaging, and more—multilingual support, CE/ISO/FDA/SGS, etc.

Clean documentation so ops can learn fast, even if English second language.

In short, you get a path that works in a plant, not just a showroom demo.

Wrap it up

If the mold has fine texture, engraving, plating, or tricky vents, pulsed laser cleaning is your friend. It’s precise, teachable, and doesn’t leave grit in slides. Pair it with CW for bulk and keep a small blasting rig for huge flats if you want. But for high-value faces, the pulsed tool is the one you’ll reach for, again and again.

Want to see which configuration fits your toolroom? Drop a note—welcome to fill out the contact BOGONG form and we’ll follow up fast.

Please fill the contact form below, and we will reply fast.