-

Calle Shunhua, ciudad de Jinan, Shandong

Fiber Laser Cutting Machine for HVAC Ductwork

Fiber Laser Cutting Machine for HVAC: cleaner edges, tighter seals, faster flow. Explore BOGONG LASER® systems and get a duct shop plan that just works.

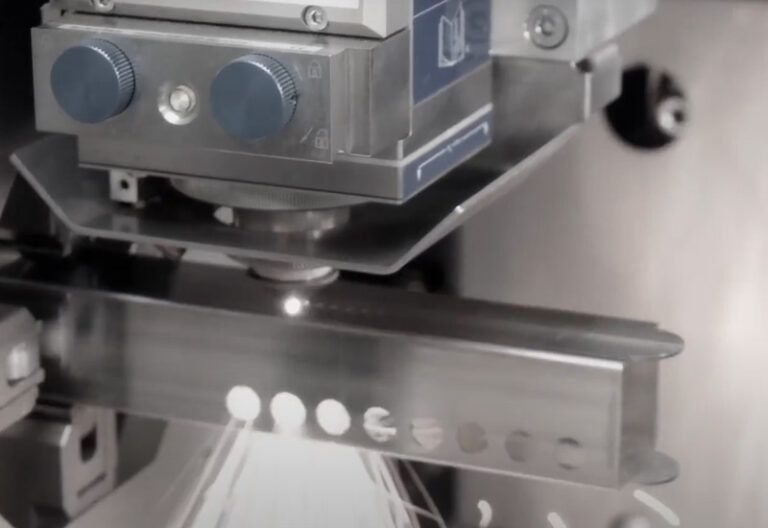

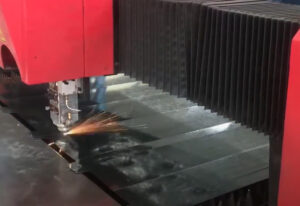

HVAC ductwork got tougher. Projects push tighter tolerances, lighter materials, and higher energy-efficiency targets.Old-school cutting fights this reality. Plasma rips through sheet but leaves rough edges and extra dross. CO₂ lasers can cut clean, but the upkeep and energy burn don’t love thin galvanized all day.A Fiber Laser Cutting Machine lands where modern duct shops live: thin gauge, complex shapes, rapid changeovers, and airtight goals. It holds edge quality steady, shrinks rework, and keeps throughput up.

Why Fiber Laser Cutting Machines Are Essential for HVAC Ductwork

Principales ventajas

Alta precisión

Micrometer-class behavior on thin sheet means crisp notches, tight corners, and small slots that don’t go egg-shaped. Your seam locks seat; your bends close without fighting springback.Versatilidad de materiales

One tool cuts galvanized steel, stainless, and aluminum used across duct systems. No drama swapping jobs. No baby-sitting between metals.

Here is a video showing the BOGONG laser cutting machine for a variety of materials.

Fiber & CO2 Laser Cutting Machine | BOGONG 1313 Pro Cutting Metal / Wood/ Acrylic etc

Eficiencia energética

Compared to legacy lasers, fiber tech sips power. Lower heat input and a simpler path keep uptime high and operating costs sane over the long haul.Speed and Productivity

Short pierces. Smart lead-ins. Small kerf. With tight nesting, you lift more finished parts per shift—and you stop living at the deburr bench.

Quick shop table — fiber vs the usual suspects

| Topic | Máquina de corte por láser de fibra | Plasma | Láser de CO₂ |

|---|---|---|---|

| Thin-gauge edge | Clean, bright-edge with right gas | Rougher, more dross | Clean, higher upkeep |

| Small features | Stable kerf, less oval holes | Struggles on tiny vents | Decent, slower on changeovers |

| Assist gas | Nitrogen for clean, oxygen for speed cases | Air/oxygen blends | Similar gases, more maintenance |

| Heat input | Low (less warp) | Higher | Medio |

| Changeovers | Quick program swaps | Quick | Slower adjustments |

HVAC Industry Needs

Reduce leaks in duct joints: smoother edges seat better in Pittsburgh or flange systems; sealant spreads even, fewer weird gaps.

Airtight seals for energy efficiency: consistent kerf means parts align; you’re not chasing pinholes later during test.

Clean bends: low heat input keeps thin galvanized from oil-canning. Brakes love stable blanks.

High-mix, high-change: fiber flips jobs fast,which can handle the rush oreders.

HVAC fit table — what fiber solves

| Pain | Why it happens | Fiber fix |

|---|---|---|

| Burrs ruin the seam | Wrong gas, worn nozzle, sloppy focus | Nitrogen cut, check nozzle wear, lock focus height |

| Tip-up kills parts | Thin sheet moves, bad lead-ins | Micro-tabs + lead-ins in scrap + tighter nest |

| Pierce spatter pits | Long pierce on thin galv | Short pierce profiles + pre-pierce off part |

| Oval small holes | Thermal load + pathing | Slot geometry + burst cut strategies |

Why Choose BOGONG Machine?

Experiencia demostrada

BOGONG LASER® builds the category. As a Fabricante de máquinas de corte por láser de fibra óptica with global B2B reach, we cover sheet, tube, combo, bevel, and automation so you grow from blanks to full kits without duct-tape workflows. Certifications (CE, ISO9001, SGS, FDA) help your procurement and compliance team sleep at night. We support OEM/ODM so the machine fits your parts.

Relevant BOGONG models (click to view):

Máquina de corte por láser de fibra 5050 — compact footprint for small HVAC blanks, fixtures, and detail plates.

Máquina de corte por láser de fibra 6000W-40KW — headroom for thicker accessories and structural bits in the same cell.

Máquina de corte láser de tubos de carga automática — hangers, supports, and round branch lines flow without babysit.

Cortadora de metal por láser de fibra — bread-and-butter sheet cutting for galvanized duct blanks.

Pain points we solve (and how)

Pain: sheet flutter and micro-tip-up

Fix: tighter nesting with micro-joints; tuned lead-ins; tabbing strategy that keeps parts stable but breaks clean by hand.

Pain: edge burr wrecks the seam

Fix: nitrogen cutting on galv; keep focus height tight; check nozzle wear. One wrong nozzle and you chase burrs all shift.

Pain: pierce spatter pits the sheet

Fix: pre-pierce outside the part line, lead-in from the scrap; short pierce times; good gas flow. Spatter goes somewhere—not on your part.

Pain: small holes go oval

Fix: switch to slot or key-hole geometry below a certain diameter; use burst cut strategies; don’t force “true circles” when slots do the job.

Pain: downline bottlenecks

Fix: cut-to-kit. Sort and stack by assembly, not by part number. The cutter should feed forming and welding without a sorting picnic.

Workflow: from drawing to duct

Keep the chain simple:

Import DXF/STEP from your design or BIM.

CAM applies pierce rules, lead-ins, kerf comp, and nests.

Cut with verified gas and height presets for galv vs stainless.

Sort to kits; label at offload; push to forming.

Close the loop: scan the kit; mark complete in MRP.

BOGONG’s team helps you tune these rules so you don’t reinvent the wheel every job. A Fiber Laser Cutting Machine Manufacturer who’s seen many duct shops will bring proven defaults.

Resumen

[/vc_column_text][vc_column_text css=””]Modern HVAC ductwork demands clean edges, airtight fits, and fast turns. A Máquina de corte por láser de fibra delivers the precision and pace without the rework tax. Choose a partner that ships the whole flow—machines, software, and practical know-how. LÁSER BOGONG, a global Fiber Laser Cutting Machine Factory, helps you stand up a line that cuts more, fixes less, and stays safe.

Want tailored advice for your project?

Drop your details in the BOGONG contact form.