Features of the Portable Fiber Laser Welding Machine

⇲ Delivers high laser energy density with a minimal thermal effect area, reducing the risk of deformation and eliminating the need for extensive subsequent processing.

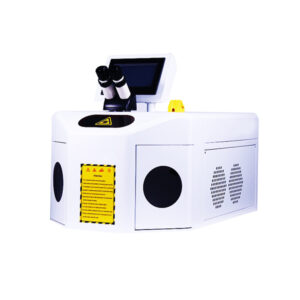

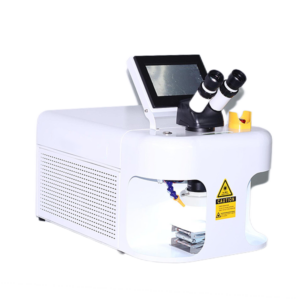

⇲ Compact all-in-one control cabinet that includes the laser generator, power pack, industrial water chiller, and controller—powerful yet easy to move.

⇲ Supports various welding techniques, including spot, stitch, nail, butt, lap, splice, edge, stack, crimp, and tee welding.

⇲ Advanced detection and protection features ensure stable long-term operation, minimizing potential losses and safety risks.

⇲ Non-contact operation is stress-free, noiseless, and environmentally friendly, aligning with green processing standards.

⇲ Produces high-quality welds with a smooth, clean finish.

⇲ Communication capabilities allow real-time monitoring of all laser data.

⇲ Equipped with a specialized fiber for welding tiny solder bumps.

⇲ High-quality fiber laser beam ensures high conversion efficiency, resulting in quick processing speed, high aspect ratio, and strong welds.

⇲ An advanced spectral system reduces energy loss, ensuring uniform laser energy across all fibers.

⇲ Use optical fiber transmission for remote welding and can easily integrate with automatic workbenches, manipulators, and assembly lines, resulting in more uniform light spots and aesthetically pleasing solder joints.

⇲ Multiple input and output signals facilitate automated production and assembly line integration.

⇲ Eco-friendly solder joints exhibit strength and toughness comparable to or exceeding that of the base metal.

⇲ User-friendly touch screen interface for simple setup and operation, with an intuitive operating system that’s easy to learn.

⇲ A variety of angled nozzles and specifications for wire feed nozzles are available to accommodate different welding project requirements.