-

Дорога Шуньхуа, місто Цзінань, провінція Шаньдун

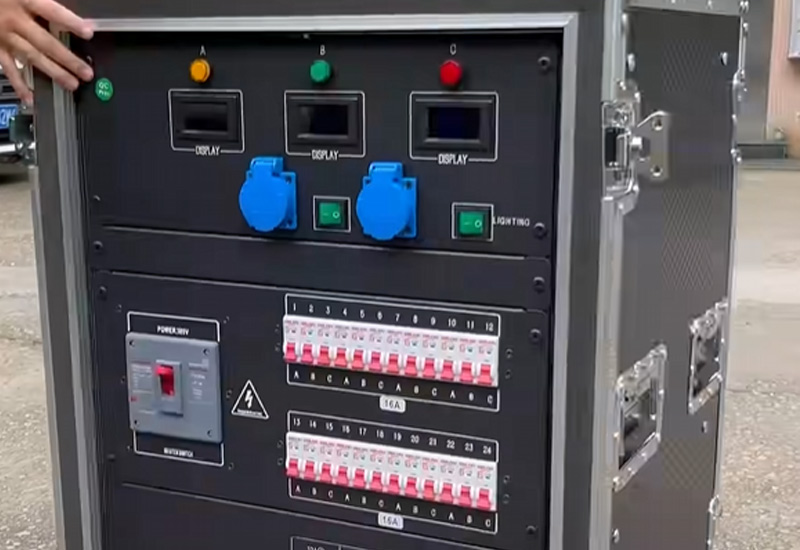

Bulk Procurement Laser Cutting Machines for Power Distribution Cabinets

Bulk-buy Laser Cutting Machines for cabinet lines: choose the right power, gas, and automation. Cut rework, speed flow. Talk with BOGONG LASER to plan your line.

Power-distribution cabinets live in light-gauge sheet, mixed SKUs, deadlines. Laser Cutting Machineit can hit takt time, keep edges clean, and stop rework from eating the margin.

From cabinet specs back to the machine choice

Most cabinet shells, doors, and mounting plates sit in the thin-sheet world. That means speed on pierce, smooth corner control, stable kerf, and steady material flow matter more than anything. So we spec from parts backward:

Light-gauge steel and coated sheet? You want high acceleration, clean micro-joints, and a nesting engine that won’t choke on lots of small apertures.

Downstream weld/paint? Edge color and dross must stay predictable, or finishing will scream.

Power & table size for the light-gauge reality

Chasing max power alone is a trap. In cabinet parts, acceleration and path planning beat top speed on a straight line. A balanced fiber Laser Cutting Machine with a common table format (e.g., sheets that fit standard panel blanks) usually wins on unit cost. Bigger beds make sense only if your nests truly need them, and your crane/tower flow can keep up.

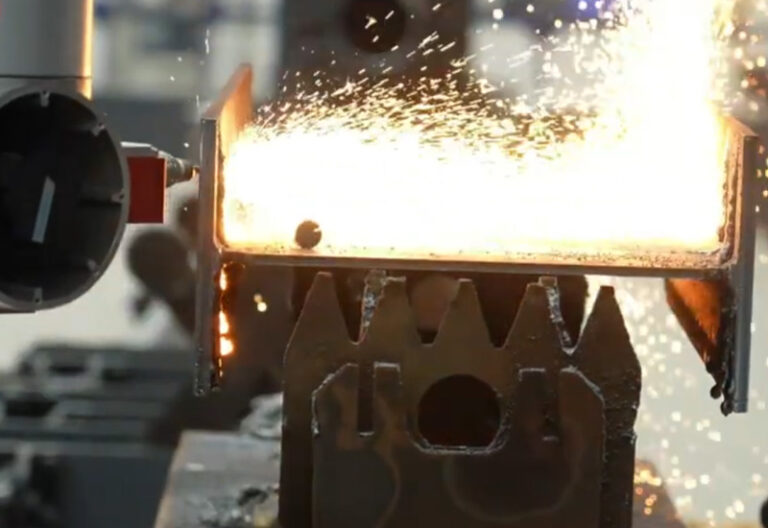

And here is video shows how BOGONG laser cutting machine working.

600*500mm fiber laser cutter for metal

Automation removes waiting, not just labor

Shuttle tables, loaders, towers—these don’t just “save hands.” They crush idle time. When sheets arrive just-in-time and parts exit to a kitted stack by order, the laser stops waiting and starts earning. That’s the lever that scales.

Typical bottleneck and fix matrix

| Bottleneck symptom | What fixes it | Why it matters | Buyer checkpoint |

|---|---|---|---|

| Machine sits “ready” but no sheet | Loader + tower with FIFO lanes | Fewer start/stop gaps, stable cycle flow | Ask for live queue view and mis-pick alarms |

| Parts pile up near shuttle | Offload sorting + cart/kitting | Faster hand-off to press brake & weld | Color-coded carts, barcode to traveler |

| Frequent re-nests mid-shift | Better nesting rules + scrap box logic | Higher yield, fewer restarts | Show actual cabinet BOM nests, not samples |

| Long changeovers on mix | Mixed-thickness strategy + nozzle quick-change | Keeps takt even when orders jump | Try a mixed job run in the demo |

Assist gas playbook for cabinets

Cabinet work splits into “looks matter” vs “hidden inside.” Surface requirements drive gas choices more than hype. Simple rules:

Exterior or visible edges need consistent color and low burr.

Interior brackets or hidden panels can tolerate “industrial pretty.”

Gas selection table

| Material & surface need | Gas option | Edge look | Shop reality | Caveats |

|---|---|---|---|---|

| Painted/visible steel | Nitrogen | Clean, minimal tint | Great for finishing flow | Gas supply must be stable and dry |

| Hidden brackets / inner panels | Clean, dry air | Fast, cost-friendly | Good for unit economics | Edge may show slight tint; prep if welding |

| Thicker mild steel plates | Oxygen | Oxide assist, steady cut | Strong on heavier stock | Heat tint; plan for downstream cleaning |

| Stainless visible parts | Nitrogen | Bright edge | Finish consistency | Keep optics clean; watch lens spatter |

Don’t forget the upstream: compressor dew point, gas manifold leaks, nozzle life, and lens contamination will drift edge quality more than any spec sheet.

Energy & upkeep: the stuff that actually hits OPEX

Uptime, optics hygiene, and filter dust control sell profit. You’ll win on:

Preventive maintenance cadence: wipe windows, watch lens pits, replace nozzles before they scar edges.

Fume & dust discipline: clogged filters slow extraction, which hurts cut quality and makes burr worse.

Operator rituals: gas purge checks, warm-up path, test coupons when switching materials.

MES handshake: push/pull nests from ERP, track OEE trends, compare shift-by-shift scrap.

Cabinet Parts and the Right Laser Cutting Machine

| Cabinet scenario | Product (click to view) | How you’d run it | Порада професіонала |

|---|---|---|---|

| Long doors & side panels (thin sheet, many apertures) | Машина для лазерного різання волокон | Nest door + side panels together; add micro-joints on long edges; swap shuttles while the next sheet queues. | Keep a tab map in the traveler; corner ramp-down + clean optics = smooth paint flow. |

| Internal brackets & inner panels (finish less critical) | Машина для лазерного різання волокон | Batch “inner-part families”; consider clean, dry air for industrial-grade edges; consistent bridge tabs for fast pop-out. | Run a quick coupon after material change; check sheet flatness if tiny slots raise burr. |

| Frames, cable-tray pieces, angle/box tube | Лазерний верстат для різання труб з автоматичним завантаженням | Feed lengths from the auto loader; etch marks for bend/orientation; kit frames straight to weld. | Use zero-point fixtures at weld; barcode the traveler to avoid left/right mixups. |

| Busbar windows, chamfers, groove prep (visible edges) | Машина для лазерного різання конічного волокна | Program bevels in CAM; verify kerf comp on angles; nest so bevel direction matches clamps. | Keep a short bevel QC (angle, land width, edge look); check gas dryness + lens pits first. |

| One cell for sheet and tube (high-mix footprint) | Лазерна машина для комбінованого лазерного різання пластин і труб | Morning panels, afternoon frames; one operator toggles modes while shuttle/chuck keeps feeding. | Lock a changeover ritual (nozzle set, focus check, purge); track OEE by sheet vs tube. |

Sourcing at scale: factory checks that matter

When you evaluate a Laser Cutting Machine Factory, look for:

In-house integration: loader/tower/laser/bend from one playbook is safer than patchwork.

Nesting engine maturity: bulk procurement lives or dies on yield and queue logic.

Spare parts + remote support: optics, nozzles, linear guides, sensors—can they ship fast?

Global installs and multilingual support: cabinets go everywhere; your support should too.

Certs & compliance: CE, ISO9001, SGS, FDA statements tell you they’ve done the homework.

Where BOGONG LASER fits in

You want a Laser Cutting Machine Manufacturer that doesn’t just sell iron, but helps you tune the flow. BOGONG LASER builds across fiber cutting, tube cutting, bevel cutting, and combo plate-tube platforms, with global B2B support and certifications that make audits easier. If you’re building or refreshing a cabinet line, start with a fiber platform that fits your nests, then add the right automation.

Common questions we hear

Do we need the maximum power model?

Not if your parts live in light-gauge sheet. A balanced platform with good acceleration and clean cornering usually beats raw wattage on cabinets.

Is air cutting safe for visible parts?

For hidden brackets and inner panels—awesome. For visible faces—use nitrogen or plan for finishing steps.

Can we skip the tower at first?

You can, but bulk procurement means multiple machines and shifts. Towers and loaders kill waiting. Add early if you can.

What about bevel cuts for busbar openings?

A bevel-capable fiber machine helps with chamfers and prep. Keep fixtures repeatable and double-check kerf comp on angles.

Procurement terms that save your day later

Edge-quality acceptance: describe burr limits, corner color, and hole roundness by part family.

Startup support: nesting templates for cabinet SKUs, tab strategies, and a “first 30-days” PM.

Spares on day one: optics set, nozzle kit, filters, and a lens-clean routine written down.

MES handshake: file formats, barcode rules, traveler layout; test before sign-off.

Training: operators learn nozzle swaps, lens checks, pierce timing, basic troubleshooting.

Підсумок

If your team cuts panels, brackets, and long faces daily, start with a fiber platform and add automation. For tubes and frames around the cabinet, consider adding an auto-loading tube unit. For chamfers and groove prep, a bevel-capable system reduces post-process touch-ups. Mix and match based on your real order book, not on what looks cool.

And if you are interested in working with BOGONG, please fill the BOGONG form below.