-

Shunhua Road, cidade de Jinan, Shandong

UV Laser Marking Machine for Medical Syringe Barrels

UV marking on medical syringe barrels—clean, clear, permanent. Learn fixtures, tuning, and vision checks. Contact BOGONG LASER for a fast, practical demo.

If you need permanent, clean, readable codes on clear, thin syringe barrels, UV is the tool. It’s “cold,” it’s precise, and it plays nice with medical plastics.

Why syringe barrels are tricky (and why UV solves it)

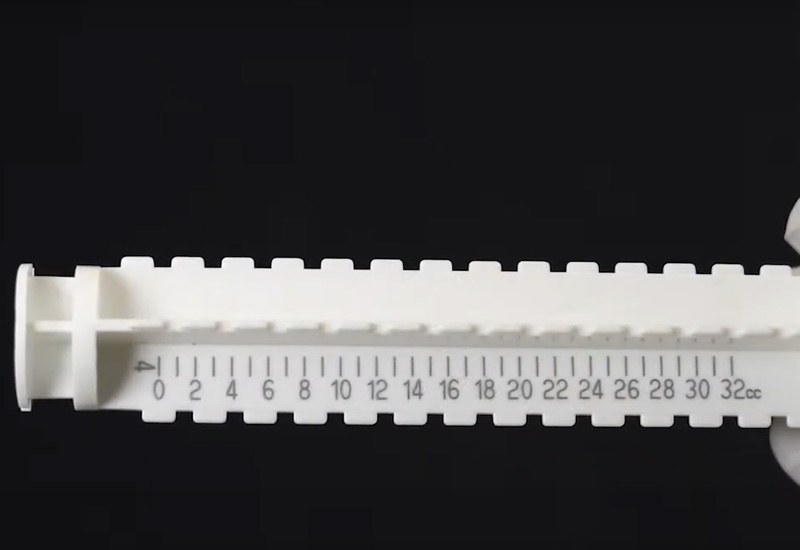

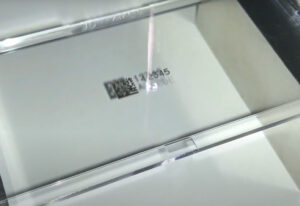

Syringe barrels look simple. They’re not. They’re thin-wall, glossy, often transparent (PC, PP, COP/COC), and curved. Labels peel. Ink transfers. Hot processes can haze the surface. That’s why a UV Máquina de marcação a laser hits the sweet spot. The shorter wavelength couples well with plastics and makes crisp text, scale marks, and DataMatrix without cooking the part. Less heat-affected zone, less risk of micro-cracks or warping. In plain words: you get contrast without wrecking clarity.

Also, the shape fights you. Curvature throws the focal plane off. UV helps here too—fine spot, tight control, good results with the right galvo path and a smart fixture.

UV gets you readable codes on clear barrels with minimal surface damage. That’s the game.

What “good” looks like on a clear barrel

Readable at the bench: not just to the naked eye, but consistent under scanner glare.

No flakes, no soot: clean mark means cleanroom-friendly.

No fogging: clarity holds, you still see the scale and the fluid.

Sticks through handling: the code stays legible after downstream steps.

And yes, this is achievable without printing inks or stickers. UV marks are ink-free, so no extra chem risk.

Materials: PC, PP, COP/COC — different plastics, different behavior

PC (Polycarbonate): takes UV marks nicely; watch for stress crazing if you overcook a second pass. Use lower energy density, slightly defocus on curved zones, and keep scan overlap tight but not saturating.

PP (Polypropylene): lower absorption; consider a pre-pass “surface activation” and slower scan in the scale zone.

COP/COC (Cyclo Olefin): loved in syringes; beautiful clarity—so protect it. Fine spot, one clean pass, and anti-glare fixturing do the trick.

A very small defocus offset on the down-slope of the barrel can stabilize contrast while avoiding overburn. Don’t chase crazy deep marks—shallow, crisp surface reactions are enough.

Shop-floor checklist

Focus & standoff: Curved part? Either rotate the barrel or use a 3D head to keep the spot “on.”

Pulse overlap: Too high = haze. Too low = grainy edge. You want just-enough overlap to “close” features without frosting.

Hatch angle & pitch: Cross-hatching tiny modules can over-matte the surface.

Speed vs. energy: Don’t crank power; let speed and repetition do small, clean reactions.

Pass strategy: One and done is best for clarity. If you must, do a light finish pass, not a second heavy pass.

A small tweak can fix a big cosmetic problem.

Fixture and pathing: the unsexy part that saves your yield

Barrels roll and reflect. A V-block with a soft roller and a tiny axial stop will stabilize the part. If you’re not rotating the barrel, program the mark path so the most critical lines sit near the best focus area. If you are rotating, sync the galvo stroke to the rotation so your module shape doesn’t stretch. Avoid beam hitting at shallow grazing angles—glare kills scanner confidence.

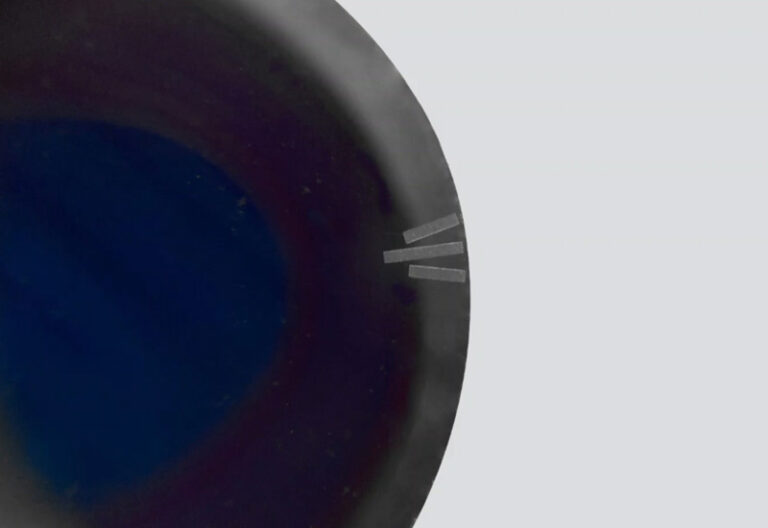

Inline vision & grading

Set a simple camera after the head. Check for:

Edge crispness (no feathered strokes).

Module integrity for 2D codes.

Barrel alignment (reject if the scale line drifts).

If the vision check is tight, your line runs steady. If not, you get rework.

Cleanroom and biocompatibility story

No inks, no solvents. Less risk of contamination. Keep the work area tidy: extract fumes at the source, wipe fixtures, and avoid re-deposit. UV dust can be very fine—catch it upstream so it doesn’t come back on your surface.

Use cases

Disposable PC barrels, label peel issues.

They ditched labels. Switched to UV marks. Codes were readable and didn’t add particulates. Main fix was fixturing: better V-block and a softer clamp pad to stop micro-slip.

COP barrels, glare ruining scans.

They rotated the part and used a short “matte band” under the code area—still transparent enough for visual scale, but reduced glare. The code read first-try on the line.

PP barrel, dull contrast.

A two-stage path (light “prep” scan + main pass) lifted contrast without going deeper. They also changed hatch pitch a hair. That’s it. Small changes, big difference.

Choose the right BOGONG machine for different scence

For clear plastics on curved and delicate parts, Máquina de marcação a laser UV—compact, UV wavelength for minimal heat footprint.

Need curvature compensation and more complex contours? Máquina de marcação a laser UV 3D gives you height-map control for barrels and odd shapes.

- Starting out or need a small enclosure for clean handling? Máquina de marcação a laser para mini gabinetes keeps things neat and safe near inspection benches.

Choose the path that fits

| Situation | Good choice | Why it works |

|---|---|---|

| Clear, thin COP/COC barrel, need fine scale + tiny logo | Máquina de marcação a laser UV | Fine spot reacts at surface; low HAZ preserves clarity |

| Curved part with multiple heights or taper | Máquina de marcação a laser UV 3D | Follows contour; keeps focus across arc |

| Mixed station (metal fittings + plastic barrels) | 30W Fiber Laser Marking Machine + UV model | Fiber covers metal; UV handles plastics; shared fixture |

| Small cell near QC, tight space | Máquina de marcação a laser para mini gabinetes | Enclosed, tidy, easy to keep clean |

| Unsure which to pick | Laser Marking Machine (category) | Browse options and match to material/throughput |

How BOGONG LASER fits

We’re a Laser Marking Machine Manufacturer and Laser Marking Machine Factory serving global B2B clients. You can prototype on a UV unit, then scale with the same control software and similar fixtures. That cuts training time and reduces changeover pain. If you already run fiber heads for metal cannulas or hubs, we’ll help you integrate UV beside them—same table, two recipes, one workflow. And Certifications (CE, ISO9001, SGS, FDA-related docs) and multilingual support make approvals and cross-site rollouts simpler.

Final take

UV is a precise tool. For syringe barrels, it gives you contrast without heat drama, codes that keep reading, and a cleanroom-friendly path—if you set up fixturing, vision, and a modest DOE.

Welcome to fill out the contact form on BOGONG. We’ll reply fast and keep it practical.