-

Shunhua Road, Jinan City, Shandong

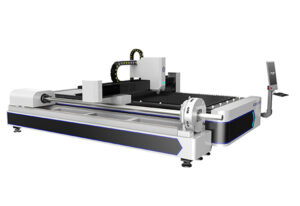

Sheet & Tube Fiber Laser Cutting Machine for Warehouse Racking

Sheet & tube fiber laser for racking: faster changeovers, cleaner edges, and real shop flow. See BOGONG LASER® options and get a plan that fits your mix.

When you build racking—uprights, beams, braces, guards, the lot. A Sheet & Tube Fiber Laser Cutting Machine lets you cut plates and tubes on the same line, keep flow steady, and react fast when engineering drops a change.

Why rack makers care about a sheet-and-tube combo

Warehouse racking isn’t just roll-formed uprights. You’ve got base plates, gussets, cross-braces, tube guards, end stops, safety panels, and custom add-ons. A combo Machine de découpe laser à fibre:

handles the flat stuff (plates, gussets, brackets) and tube stuff (beams, protectors, rails) without bouncing between two different machines;

keeps cycle time predictable when you run many part families;

cuts edges clean, so welders don’t fight burrs or recuts later.

When you already run roll forming for standard “teardrop” columns, the laser doesn’t replace it—you keep roll forming for the mass, and use the laser to cover variants, prototypes, closed-tube designs, and accessory parts. That’s the honest fit.

Quick mapping: where laser actually helps in a racking BOM

| Racking part | Form | Typical legacy process | Laser advantage | Notes |

|---|---|---|---|---|

| Base/foot plates | Sheet | Punch + drill | Clean holes, tight profiles, fast varianting | Good cosmetic edges pre-coat |

| Gussets & tabs | Sheet | Shear + drill | Microjoints, exact slots, low HAZ | Easier tack, less rework |

| Cross-braces | Sheet or tube | Saw + drill | Slot-and-tab, consistent notch geometry | Self-locating joints |

| Tube beams/guards | Tube | Saw + drill + mill | One-shot copes, miters, bevels | No fixture swap every time |

| Safety panels/end stops | Sheet & tube | Mixed | Faster ECOs; quick design tweaks | Supports short runs |

Design for assembly (DFMA) with tube-laser features

If you only cut profiles, you miss the big lever. Tube lasers let you add tabs, slots, copes, keyholes, and bevels so parts self-locate. Welders spend less time clamping.

Small example: swap a drilled hole + loose-fit tab for a laser-cut slotted tab that nests into a pocket. The cross-brace sits where it should. Tack, flip, finish. Welders smile. This part really not nice to weld before; now it behaves.

Process reality: laser + automation beat waiting and walking

Cutting head idle time kills your hourly output. Two things fix it:

Material automation for sheet — tower store, auto loader/unloader, smart queuing.

Bundle loading for tube — stabilized feeding, scanning for twist/bow, predictable offload.

Process fit comparison

| Process | Edge quality | Holes/slots | Setup/changeover | Variant agility | Automation fit |

|---|---|---|---|---|---|

| Roll forming + punching | Very good on standard patterns | Excellent (once tooled) | Excellent after dial-in | Low without re-tool | High for high volume |

| Saw + drill + mill | Fair to good | Good with time | Medium (lots to reset) | Moyen | Moyen |

| Fiber laser (sheet) | Excellent, minimal burr | Excellent | High (program swap) | Haut | High with tower |

| Fiber laser (tube) | Excellent (cope/bevel/miter) | Excellent, self-fixturing | Haut | Haut | High with bundle loader |

Where combo machines shine vs. two separate lines

A combined Sheet & Tube Fiber Laser Cutting Machine saves floor space et changeover pain when your mix is wide and lots are modest. You can switch from base plates to guard rails without walking parts across the building. Less handling equals fewer dings and less time staring at a cart waiting for the next op.

If racking demand spikes on standard SKUs, keep the roll former feeding the main line. Use the combo laser as a flex cell: quick customs, engineering changes, spare parts, short runs for special projects. It’s your pressure valve.

Choosing features that matter (and why)

Bevel cutting: chamfers for weld prep, clean fit-ups on thicker tube.

Try a Machine de découpe laser à fibre à biseau when joints need angle prep before welding.

[/vc_column_text][vc_column_text css=””]

Automatic tube loading: stable feed, less human touch, consistent cut sequence.

See Machine de découpe de tubes au laser à chargement automatique for bundle loading and continuous flow.

Plate & tube combo bed: swap modes without re-rigging a second cell.

Check Machine de découpe laser à fibre combinée pour plaques et tubes for one-platform flexibility.

High-power headroom: when you want more speed on thicker stock or multi-shift duty.

Explore Machine de découpe laser à fibre 6000W-40KW for throughput headroom.

General-purpose sheet cutting: plates, brackets, gussets, everything flat.

Start with Découpeur de métaux au laser à fibre for the bread-and-butter parts.

Quality & finish: less cleanup, better coat

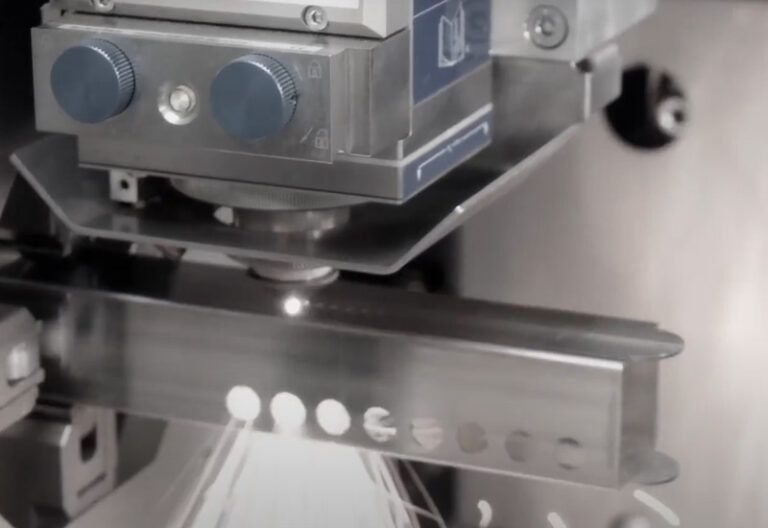

Laser edges are tight. Less burr, smaller heat-affected zone (HAZ), smoother radius on internal corners. Powder coat likes that. When beams and plates marry up with consistent geometry, you spend fewer minutes “finessing” at assembly.

Pain points we solve

Time lost at the saw. Cut bevels and notches directly on the tube laser in one program, no extra handling.

Sheets that shift during nesting. Use CAM nesting with small holding tabs and controlled entry/exit paths to keep the sheet steady until unload.

Risk of the nozzle touching the part. Keep automatic height control on and run nozzle-centering checks to avoid collisions.

Accuracy loss when you reposition long tubes. Use automatic re-grip and a planned cut order to hold tolerance from end to end.

Too much edge cleanup. Tune assist gas and piercing so holes and edges come out clean, which means less grinding later.

How to evaluate a Laser Cutting Machine Manufacturer

You want a Usine de découpe laser that supports the way you actually run:

Process coverage: sheet + tube on one platform when you need it.

Automation path: tower stores, bundle loaders, offload choices—no dead ends.

CAM & nesting: clean post, sensible lead-ins, material library you don’t fight.

Service & spares: reachable humans, docs that don’t read like riddles.

Certs & compliance: CE, ISO9001, FDA, SGS—box checked, paperwork tidy.

Global footprint: installs, multilingual support, reference sites you can visit.

BOGONG LASER® sits in that lane as a Fabricant de machines de découpe laser—cutters, engravers, cleaners, welders; OEM/ODM; certifications in order; clients across many countries; projects delivered. You don’t need fluffy words; you need a vendor that ships, supports, and grows with your mix.

Sample cell layouts

Flex cell: Plate/tube combo + small tower + offload table → feeds a weld island. Great for customs and specials.

Throughput cell: Dedicated tube laser with bundle loader + plate laser with tower → both feed a shared weld/paint line. Keeps standard SKUs flowing while you squeeze in variants.

Pick one. Test with a pilot order. Scale if the KPIs look right.

Mini FAQ for rack builders

Do I need bevel cutting for racking?

If your joints benefit from weld-prep chamfers or you want tight fit-ups on thicker tube, bevel helps. If you’re mostly thin guards, maybe not always.

Will laser replace my roll former?

No. For standard uprights, roll forming still wins. Laser fills the gap: plates, gussets, guards, special beam profiles, short-run accessories.

Can I run lights-out?

With stable material, proper sensing, and sane cut sequences, yes—at least partial lights-out windows. Start small; don’t promise the moon on day one.

What about learning curve?

CAM, nesting, and cut parameter libraries need a little love early on. After that, operators get comfy quick. It’s not rocket; it’s repetition.

What to do next (and where BOGONG fits)

If your mix is wide and lots aren’t huge, look at a combo platform.

If tube demand is heavy, prioritize a tube line with automatic loading.

If you’re bottlenecked by handling, add material automation before you add another head.

Have questions or a spec to discuss? Welcome to fill the contact form to reach BOGONG LASER®, we’ll reply quick.