-

Shunhua Road, Jinan City, Shandong

Machine à graver au laser Fournisseur

Le choix d'un fournisseur de machines à graver au laser comme BOGONG LASER nécessite d'évaluer les capacités techniques, les options de personnalisation et l'assistance après-vente.

1. Introduction

L'industrie de la gravure laser a révolutionné la fabrication en offrant précision, rapidité et polyvalence dans des secteurs tels que l'aérospatiale, l'automobile, la bijouterie et l'électronique grand public. Le choix du bon fournisseur de machines de gravure laser est essentiel pour les entreprises qui souhaitent optimiser leur productivité, réduire leurs coûts d'exploitation et conserver un avantage concurrentiel. Ce document explore les considérations stratégiques pour le choix d'un fournisseur, en mettant l'accent sur les points suivants BOGONG LASERun fabricant professionnel de lasers CNC basé en Chine. En analysant leur portefeuille de produits, leurs services de personnalisation et leurs cadres de soutien à la clientèle, ce document fournit des informations exploitables pour les entreprises qui naviguent sur le marché de la gravure laser.

2. Comprendre l'industrie de la gravure laser

2.1 Demande du marché et applications

Les machines de gravure laser sont indispensables pour les tâches nécessitant une grande précision, notamment :

- Fabrication métallique: Gravure de numéros de série, de logos ou de motifs décoratifs.

- Conception de bijoux: Personnalisation de bagues, bracelets et pendentifs.

- Fabrication industrielle: Marquage des composants pour la traçabilité.

- Art et artisanat: Création de motifs complexes sur bois, acrylique et verre.

Le marché mondial de la gravure au laser devrait croître à un taux de croissance annuel moyen de 6.8% de 2023 à 2030, sous l'effet de l'automatisation et de l'adoption de l'industrie 4.0.

2.2 Acteurs clés et paysage concurrentiel

Les principaux fournisseurs sont Trumpf, Epiloguer sur le laseret BOGONG LASERqui se différencie par sa rentabilité et sa flexibilité OEM/ODM.

3. Critères de choix d'un Machine à graver au laser Fournisseur

3.1 Expertise technique et gamme de produits

La capacité d'un fournisseur à proposer diverses machines (par exemple, fibre, CO2, UV) détermine leur adéquation à des applications variées. Par exemple :

- Lasers à fibre: Idéal pour les métaux (acier inoxydable, aluminium).

- Lasers CO2: Mieux adapté aux non-métaux (bois, tissus).

Gamme de produits de BOGONG LASER Exemple :

3.2 Capacités de personnalisation (services OEM/ODM)

Les services OEM/ODM de BOGONG LASER permettent aux clients d'adapter les machines à des besoins spécifiques, tels que stippling au pistolet ou gravure profonde sur métal.

3.3 Considérations budgétaires et analyse du retour sur investissement

Machines d'entrée de gamme (par exemple, Mini-laser à fibre optique 50W) commencent à $8,000tandis que les systèmes de qualité industrielle (par ex, Graveur laser à fibre 3D) dépassent $50,000. Une analyse détaillée du retour sur investissement doit prendre en compte le débit, les coûts de maintenance et les économies de matériaux.

4. Étude de cas : BOGONG LASER, un fournisseur de premier plan

4.1 Portefeuille de produits et innovation

Les offres de BOGONG LASER sont les suivantes :

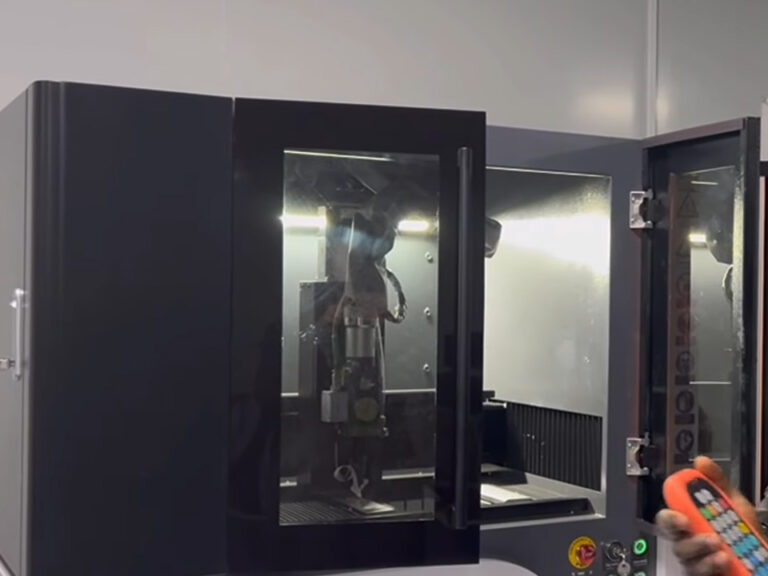

- Graveurs laser 3D: Pour les surfaces texturées et les objets courbes.

- Lasers à fibre portatifs: Des solutions portables pour le travail sur le terrain.

- Machines hybrides: Combinaison des fonctionnalités de gravure et de découpe.

4.2 Solutions centrées sur le client

L'entreprise fournit démonstrations gratuites, formation techniqueet Assistance à la clientèle 24/7Les services d'information et de conseil de l'Union européenne (UE) ont pour mission d'assurer l'intégration transparente dans les flux de travail des clients.

5. Spécifications techniques et applications

5.1 Graveurs laser à fibre et laser CO2

| Paramètres | Laser à fibre | Laser CO2 |

|---|---|---|

| Longueur d'onde | 1 064 nm | 10 600 nm |

| Compatibilité des matériaux | Métaux, plastiques | Non-métaux, organiques |

| Efficacité énergétique | Haut | Modéré |

| Coût de la maintenance | Faible | Haut |

5.2 Technologies de gravure en 2D, 2,5D et 3D

- 2D: Gravure sur surface plane (par exemple, codes-barres).

- 2.5D: Variations de profondeur à faible profondeur (par exemple, dessins en relief).

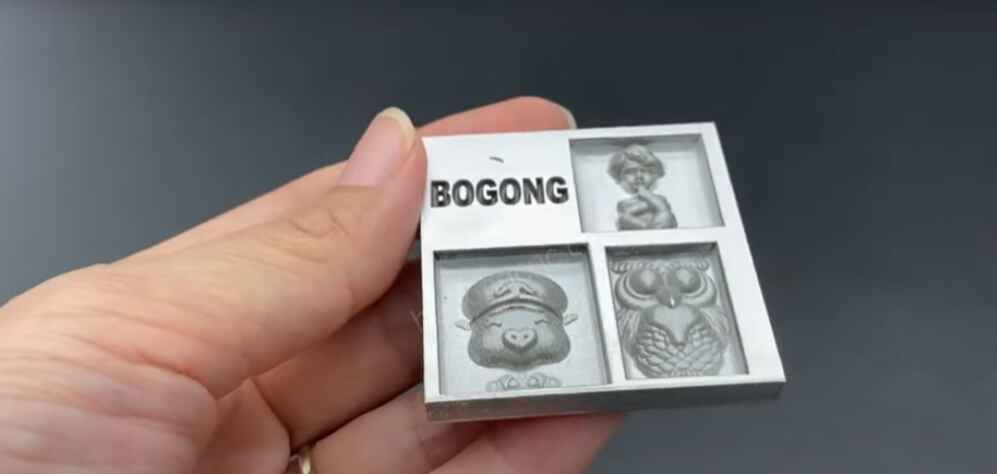

- 3D: Géométries complexes (par exemple, moules, pièces automobiles).

6. Analyse des offres de BOGONG LASER fondée sur des données

6.1 Tableau de comparaison des produits

| Modèle | Puissance | Type de laser | Fourchette de prix | Meilleur pour |

|---|---|---|---|---|

| Graveur laser pour le stippage des armes à feu | 50W | Fibre | $12,000–$15,000 | Armes à feu, équipement tactique |

| Graveur profond de métaux au laser à fibres | 100W | Impulsion | $30,000–$40,000 | Marquage d'outils industriels |

| Machine de marquage laser tout-en-un | 20W-50W | Fibre/CO2 | $10,000–$25,000 | PME, tâches multi-matériaux |

6.2 Certifications de l'industrie

BOGONG LASER cale ISO 9001, CEet Certifications FDAL'objectif est de garantir le respect des normes internationales en matière de sécurité et de qualité.

7. Tendances futures de la technologie de gravure laser

- Intégration de l'IA: Détection automatisée des défauts et optimisation des modèles.

- Lasers verts: Réduction de la consommation d'énergie et de l'empreinte carbone.

- Lasers ultrarapides: Systèmes d'impulsion nanoseconde pour la micro-gravure.

8. Conclusion

Sélection d'un Fournisseur de machines à graver au laser comme BOGONG LASER Le choix d'un produit nécessite d'évaluer les capacités techniques, les options de personnalisation et l'assistance après l'achat. Avec sa gamme de produits diversifiée et son engagement en faveur de l'innovation, BOGONG LASER illustre la manière dont un partenariat stratégique peut favoriser l'excellence opérationnelle dans le secteur de la fabrication. À mesure que l'industrie évolue, les entreprises doivent donner la priorité aux fournisseurs qui s'alignent sur leurs objectifs technologiques et financiers à long terme.