-

Shunhua Road, Jinan City, Shandong

Machines de découpe laser pour les produits en acrylique et en plastique

BOGONG Laser propose des machines de découpe laser de premier ordre pour l'acrylique et le plastique, améliorant la précision, le rendement et le retour sur investissement de votre usine. OEM/ODM, CE & ISO9001.

Finition polie à la flamme avec un minimum de retouches

Vous avez déjà saisi un panneau en acrylique et vous vous êtes demandé comment il avait obtenu ces bords brillants et sans éclats ? C'est la magie du laser qui opère. Un bon Machine de découpe laser pour l'acrylique permet d'obtenir une coupe polie à la flamme qui ne nécessite pratiquement pas de ponçage ou de polissage par la suite. Vous évitez le ponçage post-traitement et expédiez davantage de travaux.

Par exemple, un atelier de signalétique de taille moyenne est passé de la découpe à la défonceuse à une machine de découpe à la fraise. CO₂ Laser Cutter. Ils ont réduit le temps de finition de 70% - plus de poussière de ponçage dans l'air. Cela leur a permis de répondre à des appels d'offres pour des travaux plus rapides sans augmenter leurs effectifs.

Conseil de pro : Recherchez une qualité de faisceau supérieure à M²=1,1. Cela signifie un point plus serré et un trait de scie plus lisse. Des valeurs de M² inférieures se traduisent par moins de nettoyage et des angles plus nets, ce qui est essentiel lorsque vous découpez des lettres en acrylique coulé de 3 mm pour un client du secteur de la vente au détail haut de gamme.

Machine de découpe laser pour l'acrylique : Bords clairs comme du cristal

Machine de découpe laser pour le plastique : précision inférieure à 0,1 mm

Précision constante dans les coupes complexes

Lorsque vous découpez des formes complexes (supports de panneaux en nid d'abeille ou grilles d'aération pour l'électronique), la précision n'est pas négociable. Moderne Machines de découpe laser pour le plastique ont des tolérances inférieures à 0,1 mm. C'est suffisant pour les pièces à encliqueter et les boîtiers à tolérances serrées.

Prenons l'exemple d'un petit fabricant d'électronique qui avait besoin de panneaux en polycarbonate avec des supports intégrés. Il a testé une installation de laser à fibre d'un Fabricant de machines de découpe laser. La répétabilité était telle que la ligne d'assemblage a cessé de rejeter des pièces en raison d'un mauvais alignement. Elle a augmenté sa production de 30%, simplement parce que chaque coupe était parfaite.

| Epaisseur du matériau | Puissance (W) | Vitesse (mm/s) | PPI (pour CO₂) |

|---|---|---|---|

| Acrylique 3 mm | 100 W | 2 mm/s | 500 |

| 5 mm PETG | 120 W | 1,5 mm/s | 600 |

| 2 mm Polycarbonate | 80 W | 3 mm/s | 450 |

Les réglages ci-dessus sont donnés à titre indicatif. Faites toujours un essai de coupe pour régler la focalisation du faisceau et la densité des nids.

Fabricant de machines de découpe laser : Gamme de scénarios polyvalents

De la signalisation aux composants électroniques

L'une des plus grandes flexions d'un produit de haut niveau. Usine de découpe laser est le nombre de scénarios qu'il peut gérer. Vous n'êtes pas limité aux tôles plates - vous parlez de découpe de tubes, de chanfreinage, et même d'installations combinant plaques et tubes.

Signalisation et récompenses: Bords nets sur les trophées en acrylique, les dégradés et les constructions en couches.

Modèles architecturaux: Coupes de précision sur des plastiques fins pour les constructeurs de modèles réduits.

Boîtiers électroniques: Supports fendus, motifs de ventilation et entretoises dans les circuits imprimés.

Artisanat et loisirs: Pochoirs personnalisés pour bijoux, panneaux pour caissons lumineux, garnitures décoratives.

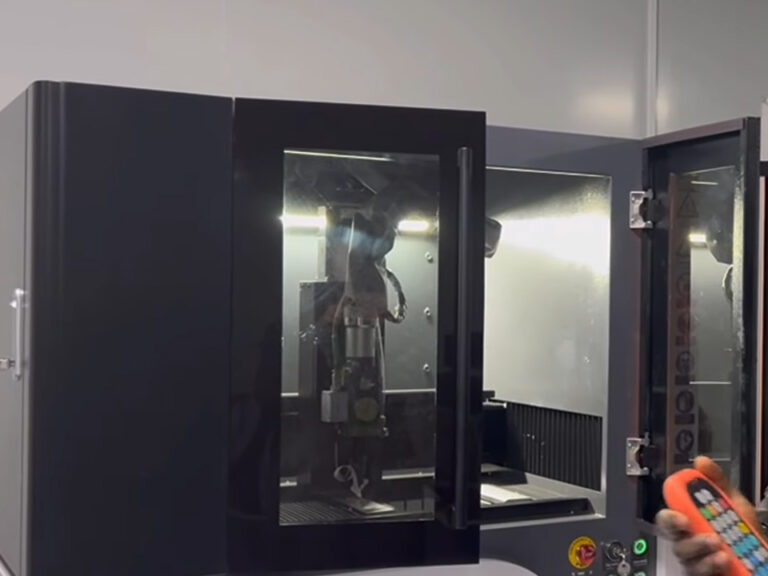

Caractéristiques de sécurité des machines de découpe laser

Gestion sans contact des procédés et des fumées

La sécurité n'est pas seulement une case à cocher, c'est un facteur de productivité. La coupe sans contact signifie qu'aucune pince n'abîme les plastiques délicats. Elle réduit également les problèmes d'usure des outils que vous rencontrez avec une défonceuse. Que reste-t-il ? Un chemin optique étanche et un bon système de ventilation pour évacuer les vapeurs d'acrylique.

Recherchez des caractéristiques telles que

Espace de travail fermé avec verrouillage.

Filtres à fumée de qualité HEPA ou des épurateurs externes.

Têtes autofocus qui vous empêchent d'effectuer des réglages manuels de la hauteur (et d'écraser des buses !).

Dans un atelier, une équipe est passée d'une découpeuse CO₂ à lit ouvert à un système Fiber fermé. Elle n'a signalé aucun incident de sécurité oculaire en un an et a réduit les temps d'arrêt de 25%, puisqu'elle n'avait plus à réaligner les miroirs après chaque poste de travail.

Je suis un bloc de texte. Cliquez sur le bouton d'édition pour modifier ce texte. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

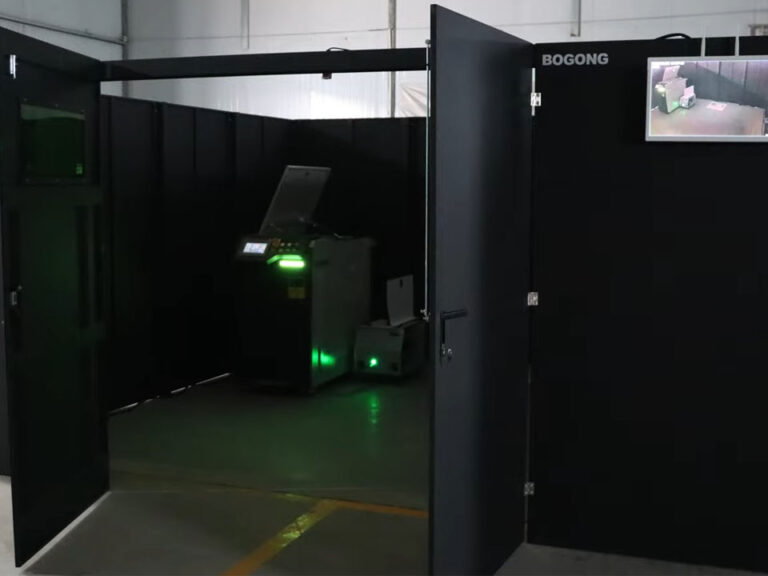

Pourquoi le laser BOGONG est en tête de peloton

Chez BOGONG Laser, nous connaissons les problèmes - retards de production, budgets de rebut, craintes en matière de sécurité - et nous construisons des machines qui y répondent. Nos Usine de découpe laser en Chine pompe à la fois du CO₂ et des fibres, tous certifiés CE, ISO9001, SGS et FDA. Vous bénéficiez d'une flexibilité OEM/ODM pour modifier les optiques, les algorithmes de nidification et même la taille du lit.

L'avantage du monde réel : Plus de 9 000 clients dans plus de 160 pays nous font confiance pour tout traiter, du nettoyage de réparation de moisissures à la décoration en acrylique de 3 mm. Nous avons même ajouté un support multilingue à l'interface utilisateur de nos contrôleurs, afin que vos opérateurs se sentent comme chez eux - pas de jargon uniquement en anglais.

Consultez notre dossier complet Catégorie de machines de découpe laser pour les spécifications et les études de cas.

Voir notre Machine de découpe laser à fibre pour le laiton, l'argent et autres.

Focus B2B et certifications

BOGONG Laser® n'est pas un simple Fabricant de machines de découpe laser-Nous sommes certifiés CE, ISO9001, SGS et FDA, ce qui vous garantit une fiabilité de niveau industriel à tout moment. De plus, l'interface utilisateur de notre contrôleur prend en charge plusieurs langues, ce qui permet à votre équipe de démarrer plus rapidement, où que vous soyez.

Logiciel d'optique et d'imbrication personnalisé OEM/ODM

Vous avez besoin d'une lentille focale spéciale pour l'acrylique ultrafin ou d'une taille de table personnalisée ? Nous réalisons les ajustements OEM/ODM en interne. Notre algorithme d'imbrication permet d'obtenir plus de pièces par feuille, ce qui réduit les déchets de matériaux et les temps d'exécution.

ConclusionSi vous avez besoin d'une solution de haute précision, à faible taux de déchets, sûre et polyvalente, une machine de découpe laser BOGONG pour l'acrylique ou le plastique est ce qu'il vous faut. Qu'il s'agisse d'un petit atelier d'artisanat ou d'une ligne de production à haut rendement, ces machines offrent la qualité de finition, la précision et le temps de fonctionnement dont vous avez besoin, sans vous ruiner en consommables ou en maintenance.