-

Shunhua Road, Jinan City, Shandong

Questions fréquemment posées

QUESTIONS FRÉQUEMMENT POSÉES

FAQ sur les machines de découpe laser

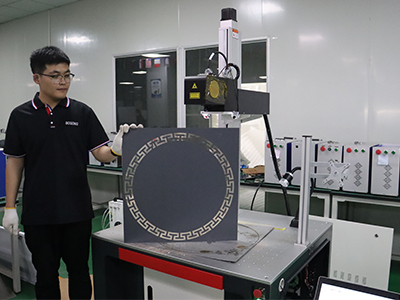

Bogong Laser’s cutting machines support a wide range of materials, including acrylic, glass, leather, metal, paper, plastic, wood, and sheet metal.

Les machines de découpe au laser à fibre peuvent découper efficacement une grande variété de métaux, y compris l'acier inoxydable, l'acier au carbone, l'aluminium, le laiton, le cuivre et les alliages.

L'épaisseur maximale dépend de la puissance du laser. Nous disposons d'une feuille de découpe qui indique la capacité de découpe de la puissance, notamment 2000w 3000w 6000w 12000w 20000w 30000w 40000w etc.

L'entretien requis comprend le nettoyage régulier de l'objectif, la vérification du système de refroidissement, l'inspection des miroirs et l'alignement correct de la machine. Des inspections de routine sont recommandées pour maintenir la machine dans un état optimal.

Les machines de découpe laser à fibre de plus de 3KW nécessitent généralement une alimentation triphasée, avec des tensions et des courants nominaux spécifiques en fonction du modèle et de la puissance du laser.

Oui, les machines de découpe au laser à fibre peuvent facilement être intégrées dans des lignes de production automatisées, y compris des systèmes de manutention et de robotique, afin d'améliorer l'efficacité.

Une formation complète est dispensée, couvrant le fonctionnement de la machine, l'entretien et les protocoles de sécurité afin de s'assurer que les opérateurs sont bien préparés.

Après la période de garantie, nous proposons des plans de service étendus et des options d'assistance pour la maintenance et les réparations, afin de garantir une assistance continue.

En règle générale, le processus de fabrication et de livraison prend de 2 à 8 semaines, en fonction du modèle spécifique et de la personnalisation.

Nous acceptons différents modes de paiement, y compris T/T (virement bancaire), et d'autres options de paiement sécurisé déterminées au cours du processus de commande.

Nous utilisons des sources laser à fibre de haute qualité provenant de fabricants réputés tels que IPG, Raycus, Max, ce qui garantit des performances fiables et une grande longévité.

Demandez-nous

FAQ sur les machines de nettoyage au laser

Une machine de nettoyage au laser est utilisée pour éliminer les contaminants tels que la rouille, la peinture, l'huile, la saleté et d'autres impuretés de diverses surfaces sans endommager le matériau sous-jacent.

Une machine de nettoyage au laser émet des faisceaux laser de haute intensité qui sont absorbés par les contaminants présents sur une surface. L'énergie du laser provoque l'évaporation ou la rupture des contaminants, ce qui permet un nettoyage efficace.

Le nettoyage au laser est souvent plus efficace que les méthodes traditionnelles telles que le sablage ou le nettoyage chimique, car il élimine les contaminants sans contact physique et minimise les dommages causés au matériau sous-jacent.

Le nettoyage au laser est souvent plus efficace que les méthodes traditionnelles telles que le sablage ou le nettoyage chimique, car il élimine les contaminants sans contact physique et minimise les dommages causés au matériau sous-jacent.

L'utilisation d'un appareil de nettoyage au laser pose-t-elle des problèmes de sécurité ?

Oui, les préoccupations en matière de sécurité comprennent les risques liés à l'exposition au laser, qui peut provoquer des lésions oculaires et des brûlures cutanées. Il est essentiel de porter un équipement de protection adéquat, notamment des lunettes de protection, et de respecter les protocoles de sécurité.

Quel est l'entretien d'une machine de nettoyage laser ?

Maintenance typically includes regular cleaning of laser lenses, checking cooling systems if your laser cleaning machine with water chiller, and conducting routine inspections to ensure all components are functioning properly.

Les machines de nettoyage laser à impulsion de 100W 200W 300W nécessitent généralement une alimentation électrique unique de 220V/110V, les nettoyeurs laser à impulsion de 500W 1000W 2000W ont besoin d'une alimentation électrique triphasée de 380V, avec une tension et un ampérage spécifiques en fonction du modèle. Les nettoyeurs laser CW 1000w 2000w ont besoin d'une alimentation 220V simple, les nettoyeurs laser CW 3000W 6000W ont besoin d'une alimentation triphasée 380V.

Lors du choix d'une machine, il faut tenir compte de facteurs tels que les types de surfaces à nettoyer, le niveau de contamination, la vitesse de nettoyage requise et l'alimentation électrique disponible.

Nous proposons une formation complète aux opérateurs, couvrant le fonctionnement de la machine, les procédures d'entretien et les protocoles de sécurité afin de garantir une utilisation sûre et efficace.

Après la période de garantie, nous proposons des plans de service étendus et une assistance pour vous aider à entretenir et à dépanner votre machine.

Le délai de fabrication et de livraison est généralement de 7 à 10 jours ouvrables pour les machines standard, les autres dépendant du modèle spécifique et des personnalisations demandées.

Nous acceptons diverses options de paiement, y compris le transfert bancaire (T/T) et d'autres méthodes de paiement sécurisées.

Nos machines de nettoyage au laser utilisent des sources laser de haute qualité provenant de fabricants réputés tels que Raycus ou JPT MOPA Laser, afin de garantir leur fiabilité et leurs performances.

Oui, nous nous occupons de l'expédition et de la livraison à l'adresse que vous nous avez indiquée, en assurant une logistique adéquate.

Oui

FAQ sur les machines de gravure au laser

Nos machines peuvent graver une grande variété de matériaux, notamment les métaux, le bois, les plastiques, le verre, le cuir et la céramique.

Oui, la profondeur et le style de la gravure peuvent être contrôlés avec précision pour obtenir des effets allant de marques peu profondes à des gravures profondes.

Un nettoyage régulier de l'objectif, des miroirs et de la zone de travail est recommandé, ainsi qu'un étalonnage périodique pour garantir des performances optimales.

Oui, les gravures au laser sont permanentes et résistent à l'usure, à la décoloration et aux dommages causés par l'environnement.

FAQ sur les machines à souder au laser

Le soudage laser est un procédé de soudage qui utilise un faisceau laser de forte puissance pour fondre et assembler des matériaux, généralement des métaux, en créant une liaison solide avec une distorsion minimale et des zones affectées par la chaleur.

Les machines à souder au laser peuvent souder une large gamme de matériaux, y compris l'acier inoxydable, l'acier au carbone, l'aluminium, le cuivre et d'autres alliages.

Les avantages sont notamment une plus grande précision, un apport de chaleur réduit, une distorsion minimale, la possibilité de souder des matériaux minces et des vitesses de traitement plus rapides, ce qui permet de raccourcir les temps de cycle.

Utilisez des équipements de sécurité appropriés, notamment des lunettes de protection, des gants et des tabliers. Veillez à une bonne ventilation, suivez les protocoles de sécurité et sachez où se trouvent les boutons d'arrêt d'urgence.

L'entretien régulier comprend le nettoyage des optiques, la vérification du système de refroidissement, l'inspection des câbles et des connexions, et l'assurance d'un étalonnage et d'un alignement corrects.

Oui, de nombreuses machines à souder au laser peuvent être intégrées dans des lignes de production automatisées pour une efficacité et une cohérence accrues grâce à la robotique et à d'autres technologies d'automatisation.

Replacement parts can be obtained from us, or you can purchase from laser head manufacturer. It’s important to use genuine parts to ensure compatibility and performance.

Nous proposons une formation complète qui comprend le fonctionnement des machines, les procédures d'entretien, les pratiques de sécurité et les techniques de dépannage afin de garantir une utilisation efficace de l'équipement.

The lead time for production and delivery is typically 5-10 working days for standard machine. Others depending on the specific model and any customization requested.

Nous acceptons différents modes de paiement, notamment le transfert bancaire (T/T), ainsi que d'autres options sécurisées en fonction des préférences du client.

Source laser Raycus, Max disponible. IPG en option.

FAQ sur les machines de marquage au laser

Nos machines peuvent marquer les métaux, les plastiques, le verre, le cuir, le bois et bien d'autres choses encore, en produisant des marques claires et permanentes.

Oui, les marquages au laser sont généralement permanents et résistants à l'usure, à la décoloration et aux influences environnementales, ce qui garantit leur longévité.

Les machines de marquage laser peuvent créer différents types de marquages, notamment des textes, des logos, des codes-barres, des codes QR, des numéros de série et des dessins complexes.

Nous fournissons des tutoriels et des manuels pour vous aider à apprendre à faire fonctionner la machine laser et le logiciel, et nos employés qui parlent anglais peuvent vous guider un par un.

Portez toujours des lunettes de protection appropriées, assurez une bonne ventilation et suivez les protocoles de sécurité. Soyez conscient de la zone d'action du laser et utilisez des écrans de protection si nécessaire.

L'entretien régulier comprend le nettoyage des lentilles, la vérification de l'alignement, l'inspection des systèmes de refroidissement s'il s'agit d'un refroidisseur d'eau, et la mise à jour des logiciels pour garantir des performances optimales.

Le marquage laser peut être effectué sur la surface du cylindre à l'aide d'un dispositif rotatif.

EZCAD Software, Il peut prendre en charge des formats de fichiers courants tels que DXF, AI et PLT.

Nous offrons généralement une garantie de deux ans, ainsi qu'une assistance technique et un accès aux pièces de rechange pendant la période de garantie.

Après la période de garantie, des plans de service étendus et des options d'assistance sont disponibles pour l'entretien et les réparations.

Le délai de production et de livraison est généralement de 5 à 7 jours ouvrables. Contactez l'équipe de BOGONG pour savoir si la machine est en stock.

Oui, nous fournissons des vidéos d'instruction démontrant le fonctionnement de la machine de marquage laser, y compris les procédures d'installation, d'utilisation et d'entretien.

Pour passer une commande, vous pouvez contacter notre équipe de vente pour discuter de vos besoins, recevoir un devis et finaliser les détails de la commande. Nous vous guiderons tout au long du processus.