-

Shunhua Road, Jinan City, Shandong

Indicateurs clés et stratégies d'achat pour les machines de gravure laser de haute qualité

Pour choisir une machine de gravure laser, il faut trouver un équilibre entre les caractéristiques techniques (type de laser, puissance, précision), le budget et les besoins opérationnels. Le portefeuille diversifié de BOGONG LASER illustre la manière dont les fabricants peuvent répondre aux besoins des marchés de niche et des marchés industriels.

Le marché mondial de la gravure laser devrait croître à un taux de croissance annuel moyen de 6,81 % d'ici à 2030, grâce à la demande de précision, d'automatisation et de polyvalence des matériaux (Market Research Future, 2023). Toutefois, les acheteurs sont confrontés à des difficultés pour s'y retrouver dans les spécifications techniques, les contraintes budgétaires et les exigences spécifiques à l'application. En utilisant le portefeuille de produits de BOGONG LASER comme étude de cas, ce document identifie les paramètres d'évaluation critiques et les stratégies d'achat.

1. Indicateurs techniques de base pour Machines de gravure au laser

Type de laser et longueur d'onde

Différents types de laser conviennent à des matériaux et à des applications spécifiques :

| Type de laser | Longueur d'onde | Matériaux idéaux | Cas d'utilisation | Exemple de BOGONG LASER |

|---|---|---|---|---|

| Laser à fibre | 1 064 nm | Métaux, plastiques | Gravure profonde, marquage industriel | Machine de marquage laser à fibre 30W |

| CO₂ Laser | 10,6 μm | Bois, acrylique, tissu | Gravure artistique, signalétique | Machine de marquage laser CO2 |

| Laser UV | 355 nm | Verre, céramique | Micro-gravure à haute résolution | Machine de marquage laser UV 3D |

Les lasers à fibre dominent la gravure des métaux, tandis que les lasers CO₂ excellent dans les matériaux non métalliques. Les lasers UV sont une niche, mais ils sont essentiels pour les matériaux fragiles.

Puissance et rapidité

La puissance (W) détermine la profondeur et la vitesse de gravure :

| Gamme de puissance | Vitesse de gravure | Epaisseur du matériau | Exemple de produit |

|---|---|---|---|

| 20-30W | 7 000 mm/s | ≤3 mm (acier) | Laser à fibre portatif |

| 50-100W | 12 000 mm/s | ≤10 mm (acier) | Graveur à fibre divisée 50W |

Compromis: Une puissance plus élevée augmente le débit mais augmente les coûts. Les acheteurs soucieux de leur budget devraient privilégier une puissance de 30 à 50 W pour les petites entreprises.

Précision et résolution

- Précision: Mesuré en microns (µm). Les graveurs 3D de BOGONG atteignent ±5 µm pour les dessins complexes.

- Flexibilité dimensionnelle: Des machines comme le Graveur laser à fibre 3D supporter des surfaces courbes.

2. Indicateurs opérationnels et commerciaux

Allocation budgétaire

| Catégorie d'utilisateur | Fourchette budgétaire (USD) | Produit BOGONG recommandé |

|---|---|---|

| Hobbyistes | $2,000–$5,000 | Machine de marquage laser tout-en-un |

| PME | $8,000–$20,000 | Machine de gravure/découpe à laser à fibre |

| Industriel | $25,000–$50,000+ | Machine de marquage laser UV 3D |

Support après-vente

Les offres de BOGONG LASER sont les suivantes :

- Formation gratuite aux logiciels.

- Assistance technique 24 heures sur 24, 7 jours sur 7.

- Garantie de 2 ans sur les composants essentiels.

3. Cadre stratégique d'achat

Évaluation des besoins

Utilisez la liste de contrôle avant achat de BOGONG :

- Application: Gravure, découpe ou tâches hybrides ?

- Matériau: Métal (laser à fibre) vs. bois/acrylique (laser CO₂).

- Volume: La production par lots nécessite une vitesse plus élevée (50W+).

Coût total de possession (TCO)

| Facteur de coût | Laser à fibre (30W) | Laser CO₂ (40W) |

|---|---|---|

| Achat initial | $8,500 | $6,200 |

| Entretien annuel | $1,200 | $900 |

| Consommation d'énergie | $300/an | $500/an |

Aperçu: Les lasers à fibre ont des coûts initiaux plus élevés mais des dépenses énergétiques moindres pour les métaux.

La protection de l'avenir

- Les conceptions modulaires (par exemple, Split Mini Fiber Laser) permettent des mises à niveau.

- Compatibilité avec le logiciel Industry 4.0.

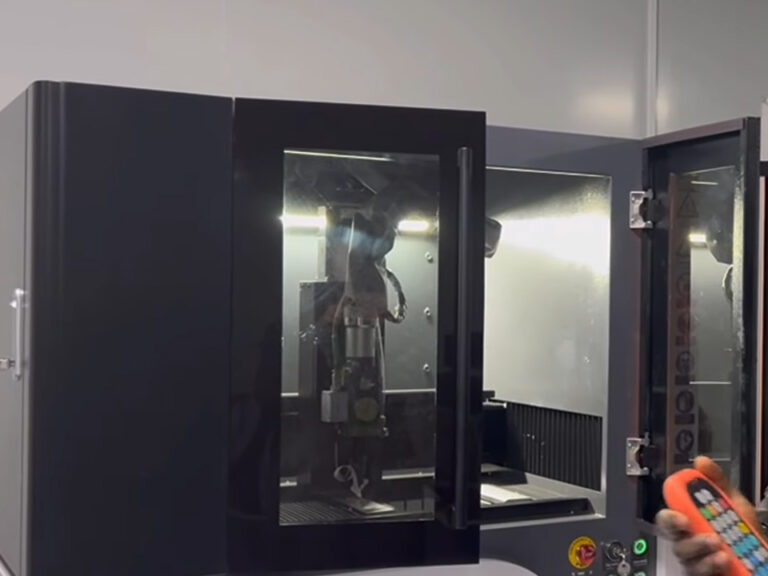

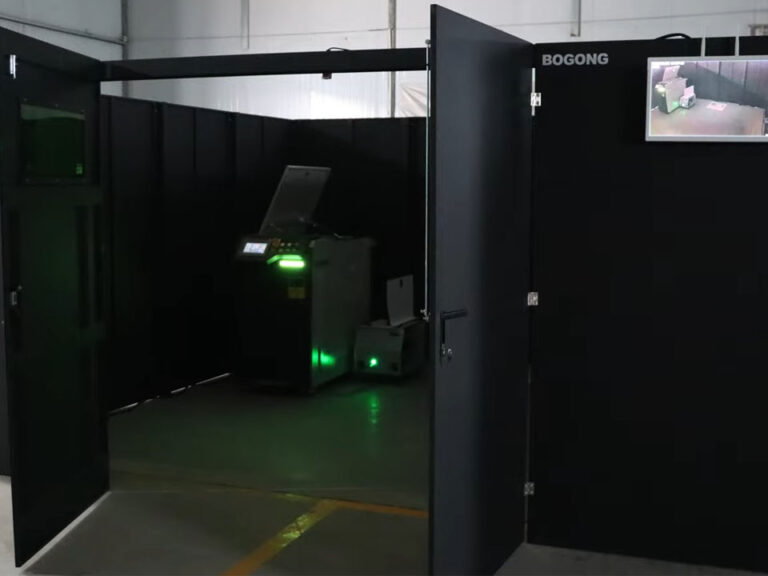

4. étude de cas : Différenciation des produits de BOGONG LASER

- Expertise de niche: Le Graveur laser pour le stippage des armes à feu se consacre à la personnalisation des armes à feu, un secteur à forte marge.

- Capacités 3D: Le graveur laser à fibre 3D permet de varier la profondeur, ce qui est essentiel pour l'aérospatiale et la bijouterie.

5. Conclusion

Pour choisir une machine de gravure laser, il faut trouver un équilibre entre les caractéristiques techniques (type de laser, puissance, précision), le budget et les besoins opérationnels. BOGONG LASER's Le portefeuille diversifié de l'entreprise illustre la manière dont les fabricants peuvent répondre aux besoins des marchés de niche et des marchés industriels. Les acheteurs doivent donner la priorité aux fournisseurs qui offrent la modularité, le service après-vente et des solutions spécifiques aux matériaux.