-

Calle Shunhua, ciudad de Jinan, Shandong

Laser Engraver Helps Custom Gifts Startup Thrive

Find out how BOGONG Laser’s precision engraving machines empower custom‑gift startups to cut production time, boost margins, and delight clients worldwide.

Laser engravers are crucial for custom-made gift startups since they make it possible for precise, functional, and individualized inscribing on a variety of materials, improving the value and appeal of presents.

What laser engraving actually fixes

- Missed deadlines. Manual carving, stamping, or chemical etching drags. A laser runs repeatable passes and turns designs around quickly.

- Inconsistent quality. Hand steps invite variation. A saved recipe keeps lines crisp across entire batches.

- Limited product range. One tool that handles wood, leather, coated metals, acrylic, and more lets you switch SKUs without retooling.

- Hidden costs. No inks to stock, no acids to handle, less cleanup, fewer rejects.

Why Custom Gifts Startups Rely on Laser Engraving Machines

Traditional strategies– hand sculpting or acid etching– take up hrs as well as risk blunders. A laser engraver pieces angle and also raster art in to wood, steel, or even acrylic with sub‑millimeter accuracy. That speed lets you:

Meet tight deadlines.

Introduce new SKUs without hiring.

Scale from hobby runs to full‑blown production.

Laser engraving isn’t a “nice to have.” It’s the backbone of a lean, agile workshop that pivots from leather keychains to metal photo plaques in minutes.

Casos prácticos

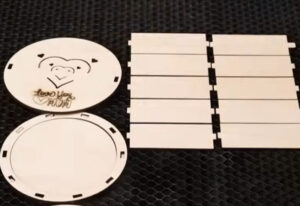

Crafting Leather Keychains

A maker loads blank leather tags onto a jig. The laser head drops into vector mode, etches a crisp logo, then fires a raster fill for shaded details. Less than a minute, each tag’s done—no messy dyes, no touch‑ups. That turnaround wins repeat business and lets you offer same‑day shipping.

It helps to see the process in action. Here’s a quick demo of sheet‑to‑gift transformation:

Silver Christmas Gift Laser Engraving Cutting Machine

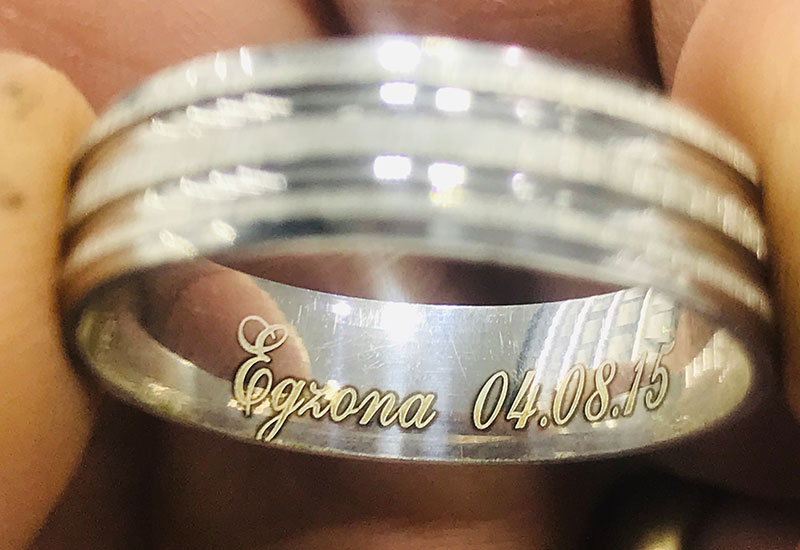

Etching Metal Plaques

Switch to a high‑power pulse setting, and you carve names and dates into stainless steel. The result? Deep engraving with sharp contrast—and zero post‑processing. Clients pay extra for that boutique finish, and you deliver at scale without slowing down.

Pick the right tool for the materials you sell

| Material focus | Best-fit laser | Why it works | Typical products |

|---|---|---|---|

| Metals and plated parts | Fiber (including MOPA) | High-contrast, durable marks, fine text | Jewelry, tags, tools, plaques |

| Polymers, coated plastics, glass | UV | Clean marks with minimal heat effect | Phone cases, pens, connectors |

| Wood, leather, paper, some rubbers, glass coatings | CO₂ | Smooth engraving/cutting on organics | Keychains, notebooks, signage |

| Curved or uneven metal | Dynamic-focus fiber | Consistent depth over contours | Rings, bands, molded parts |

Tip: many shops pair one metal-focused system with another tuned for organics and clear plastics.

Best-Fit BOGONG Machines for Custom-Gift Shops

50W Split Mini Fiber Laser Engraving Machine

Compact metal specialist for tags, rings, tools, cards—sharp, repeatable detail with a small footprint.Máquina de marcado láser CO2

Go-to for wood, leather, paper, and coated glass—clean engraving and cut-through for signs and decor.

Máquina de marcado láser UV / Grabador láser UV

Best on plastics and delicate surfaces—crisp marks with minimal heat effect for cases, pens, and acrylics.Grabador láser de fibra 3D para metal

Handles curved or uneven parts—consistent depth on rings, bands, and contoured plaques.

The following video shows some of the custom works that BOGONG has engraved in the past.

3D Laser Engraving Work Show

Why choose BOGONG

- Fast lead times and clear warranty

- OEM/ODM customization for fixtures, deep engraving, and niche workflows.

- Global shipping footprint and reliable logistics for scale-up.

- Full accessory ecosystem (rotaries, jigs) for common gift SKUs.

Conclusion: Scale Smarter with BOGONG Laser

Whether you’re etching leather tags or slicing metal ornaments, the right Máquinas de grabado láser can make your custom‑gift startup. Focus on:

Choosing a certified Laser Engraving Machine Factory

Partnering with a growth‑focused Laser Engraving Machine Manufacturer

Picking machines whose specs match your use cases

Mastering industry jargon and performance tweaks

Lean on BOGONG Laser’s gear and support. You’ll scale faster, deliver consistent quality, and turn first‑time buyers into loyal fans. That’s how a laser engraver helps your custom‑gifts venture thrive.