-

Calle Shunhua, ciudad de Jinan, Shandong

Laser Die Cutting in Packaging Printing: Benefits for Precision and Speed

Switch to laser die cutting for faster changeovers, clean edges, and flexible designs. See how BOGONG LASER machines boost packaging lines for real-world runs.

Precision that sticks with print

Registration-to-print is the daily pain. Labels wander. Window cutouts miss the artwork by a hair. Laser uses vision alignment and digital paths, so it tracks print and holds that alignment across the web. Sharp internal corners, super-tight radii, lattice patterns.

On the floor checklist

Keep web tension steady; let vision do the heavy lifting.

Use clean vector paths.

If you see haze or browning on paper/film edges, step down energy density and add air assist (or adjust focal spot).

Pair with stable laminations to prevent curl after kerf removal.

Speed isn’t only meters per minute—it’s changeover time

On a busy packaging line, “speed” = how fast you deliver finished pieces to shipping. Laser crushes changeovers: load the next file, run. Frequent promotions, seasonal wraps, versioned languages, sample packs—these scenarios tip strongly toward laser.

Where traditional wins: huge, steady volumes of the same geometry. A flatbed die under a tuned press is still a throughput monster for those marathon jobs.

Design freedom

With laser, you can stitch in micro-perfs for easy-open, etch tear tapes, breathe through micro-vents for coffee valves or fresh-produce windows, or do kiss-cut liners without digging into the carrier. You can move from prototype to pilot run to market test with the same digital cut path.

Packaging scenarios

Multi-language cartons: identical dieline, different copy. Laser switches files, not hardware.

Sampler sleeves with irregular peek-through shapes: cut the window, raster a soft score for a smooth fold, finish in one pass.

Flexible pouches needing a guided tear: laser perforation + score tuned to film stack; easy open for consumers, fewer returns from tear failures.

Premium gift boxes: intricate filigree cutouts on sleeves, no chads stuck in the die, no blown edges on coated boards when parameters are right.

Protective films: kiss-cut top layer for peel tabs; reduce waste because kerf and path accuracy stay tight.

A blunt comparison table

| What you care about | Laser die cutting | Traditional die cutting | Notes that matter |

|---|---|---|---|

| Changeover time | Very short | Tool-dependent | Laser swaps files; dies need sourcing, mounting, test pulls |

| Complex shapes | Fácil | Harder | No tool corners to round; fewer compromises |

| Consistency over long runs | Stable when tuned | Stable when tooled | Blade wear impacts dies; laser needs fume control to keep optics clean |

| Micro-features (perfs/vents/etch) | Excelente | Limitado | Laser can combine cut + score + perf |

| Very high volume, simple shape | Bien | Excelente | Tooling amortizes fast when volume is massive |

| Material flexibility | Broad (paper, films, foils) | Broad | Adjust energy density to avoid heat-affected zones |

| Storage & inventory | No dies to store | Needs die storage | Laser reduces tooling logistics |

| Change requests late in the day | Safer | Risky | Edit vector path, re-run; no tool reorder |

How to fix the hidden blockers

Edge browning / melt beads on films: reduce dwell, increase traverse speed, add air assist, run a cleaner focus. Some films really like a different pulse format; test small.

Curl after cut (laminated stocks): check heat load, balance the stack, and tweak score depth.

Soot and sticky residue: it’s not “just a smell.” Get proper fume extraction and filtration so optics stay clean and operators stay happy.

Matrix stripping surprises: laser-cut waste behaves different than die-kiss waste; plan your take-up torque and web path.

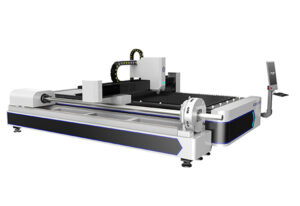

Choose the right machine

When you cut mostly paperboard, cartons, and display sleeves—and you still want to engrave marks, score lines, or kiss-cut films—CO₂ systems are the usual suspects. When you’re dealing with metals, tubes, or combo jobs (sheet + tube), fiber systems carry the load. If your factory needs both, a hybrid plan often wins.

Máquina de corte láser de tubos de carga automática — when your inserts/tubes/frames need tube cutting with auto-feed; integrates well near packaging cells for frames or handles.

Laser Plate & Tube Combo Fiber Laer Cutting Machine — sheet + tube in one footprint; handy for packaging hardware, jigs, and small-lot parts.

Máquina de grabado y corte láser CO2 — for paper/cardboard/films, mark + cut + score; a natural fit near print finishing lines.

If you need bevels/chamfers on metal fixtures to finish better, peek at the Máquina de corte láser de fibra óptica. It saves secondary ops on frames and brackets used around packaging equipment.

Why BOGONG LASER

BOGONG’s range covers CO₂ and fiber cutting platforms, so you can match tool to job without hopping between vendors. As a Manufacturer with global install base and compliance badges (CE, ISO9001, SGS, FDA, France BV), support and documentation land in your language, and spares don’t play hide-and-seek. If you’re building a new cell or upgrading a tired one, starting with a balanced cell—one Laser Cutting Machine for change-heavy work and keep your die cutter for the marathons—usually pays back in fewer headaches and more shipped boxes.

PREGUNTAS FRECUENTES

Will laser replace all dies in our Factory?

No. Keep dies for long, simple runners. Use laser where complexity or change is normal.

Can we score, perf, and cut at once?

Yes. That’s one of the biggest wins—fewer passes, fewer setups.

Will films warp?

They can. Tune energy, use air, and test on your exact laminate stack.

Can operators learn it fast?

They usually do. If they can run a modern press and read a vector path, they’re 80% there.

Final nudge

If your backlog is full of short runs and shape weirdos, laser is a cleaner way to work. Start with one cell. Point it at the jobs that drain your team’s patience. And if you need help matching a platform to your purposes, talk to BOGONG. We build and ship the machines, and we actually run them too.

Want a quick quote or a run-through?

Fill the contact form for BOGONG LASER—our team will reply fast and plain-spoken.