-

Calle Shunhua, ciudad de Jinan, Shandong

Indicadores básicos y estrategias de compra de máquinas de grabado por láser de alta calidad

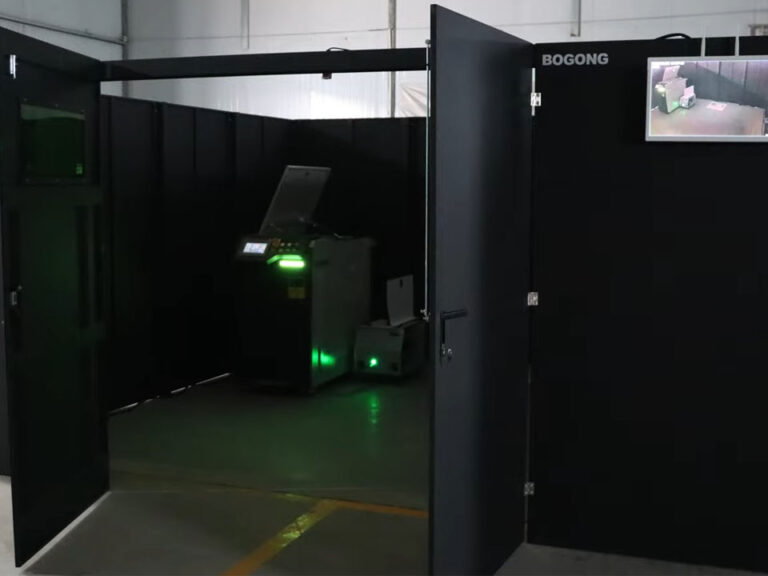

La selección de una máquina de grabado por láser requiere equilibrar las especificaciones técnicas (tipo de láser, potencia, precisión) con el presupuesto y las necesidades operativas. La cartera diversificada de BOGONG LASER es un ejemplo de cómo los fabricantes pueden abordar nichos de mercado y mercados industriales.

Se prevé que el mercado mundial del grabado por láser crezca a una TCAC de 6,8% de aquí a 2030, impulsado por la demanda de precisión, automatización y versatilidad de materiales (Market Research Future, 2023). Sin embargo, los compradores se enfrentan a retos a la hora de navegar por las especificaciones técnicas, las limitaciones presupuestarias y los requisitos específicos de la aplicación. Utilizando la cartera de productos de BOGONG LASER como caso de estudio, este documento identifica las métricas críticas de evaluación y las estrategias de compra.

1. Indicadores técnicos básicos para Máquinas de grabado láser

Tipo de láser y longitud de onda

Los distintos tipos de láser se adaptan a materiales y aplicaciones específicos:

| Tipo láser | Longitud de onda | Materiales ideales | Casos prácticos | Ejemplo de BOGONG LASER |

|---|---|---|---|---|

| Láser de fibra óptica | 1.064 nm | Metales, plásticos | Grabado profundo, marcaje industrial | Máquina de marcado láser de fibra de 30W |

| Láser de CO₂ | 10,6 μm | Madera, acrílico, tela | Grabado artístico, señalización | Máquina de marcado láser CO2 |

| Láser UV | 355 nm | Vidrio, cerámica | Micrograbado de alta resolución | Máquina de marcado láser UV 3D |

Los láseres de fibra dominan el grabado de metales, mientras que los láseres de CO₂ destacan en los no metálicos. Los láseres UV son muy especializados, pero fundamentales para materiales frágiles.

Potencia y velocidad

La potencia (W) determina la profundidad y la velocidad de grabado:

| Rango de potencia | Velocidad de grabado | Material Grosor | Ejemplo de producto |

|---|---|---|---|

| 20-30W | 7.000 mm/s | ≤3 mm (acero) | Láser de fibra óptica portátil |

| 50-100W | 12.000 mm/s | ≤10 mm (acero) | Grabador de fibra dividida de 50 W |

Trade-off: Una mayor potencia aumenta el rendimiento, pero incrementa los costes. Los compradores con presupuesto ajustado deberían dar prioridad a los de 30-50 W para pequeñas empresas.

Precisión y resolución

- Precisión: Medido en micras (µm). Los grabadores 3D de BOGONG alcanzan ±5 µm para diseños intrincados.

- Flexibilidad dimensional: Máquinas como la Grabador láser de fibra 3D soportar superficies curvas.

2. Indicadores operativos y comerciales

Asignación presupuestaria

| Categoría de usuario | Presupuesto (USD) | Producto BOGONG recomendado |

|---|---|---|

| Aficionados | $2,000–$5,000 | Máquina de marcado láser todo en uno |

| PYME | $8,000–$20,000 | Máquina de grabado y corte láser de fibra óptica |

| Industrial | $25,000–$50,000+ | Máquina de marcado láser UV 3D |

Asistencia posventa

La oferta de BOGONG LASER incluye:

- Formación gratuita en software.

- Asistencia técnica 24 horas al día, 7 días a la semana.

- 2 años de garantía para los componentes críticos.

3. Marco estratégico de compras

Evaluación de las necesidades

Utilice la lista de comprobación previa a la compra de BOGONG de:

- Aplicación: ¿Grabado, corte o tareas híbridas?

- Material: Metal (láser de fibra) frente a madera/acrílico (láser de CO₂).

- Volumen: La producción por lotes requiere mayor velocidad (50W+).

Coste total de propiedad (TCO)

| Factor de coste | Láser de fibra (30 W) | Láser de CO₂ (40 W) |

|---|---|---|

| Compra inicial | $8,500 | $6,200 |

| Mantenimiento anual | $1,200 | $900 |

| Consumo de energía | $300/año | $500/año |

Insight: Los láseres de fibra tienen costes iniciales más elevados, pero menores gastos de energía para los metales.

A prueba de futuro

- Los diseños modulares (por ejemplo, Split Mini Fiber Laser) permiten actualizaciones.

- Compatibilidad con el software Industria 4.0.

4.Estudio de caso: Diferenciación de productos de BOGONG LASER

- Especialización: La Grabador láser para punteado de armas se dedica a la personalización de armas de fuego, un sector con grandes márgenes.

- Capacidades 3D: El grabador láser de fibra 3D permite variar la profundidad, algo fundamental para la industria aeroespacial y la joyería.

5. Conclusión

La selección de una máquina de grabado por láser requiere equilibrar las especificaciones técnicas (tipo de láser, potencia, precisión) con el presupuesto y las necesidades operativas. LÁSER BOGONG La diversificación de la cartera es un ejemplo de cómo los fabricantes pueden abordar nichos de mercado y mercados industriales. Los compradores deben dar prioridad a los proveedores que ofrezcan modularidad, asistencia posventa y soluciones específicas para cada material.