-

طريق شونهوا، مدينة جينان، شاندونغ

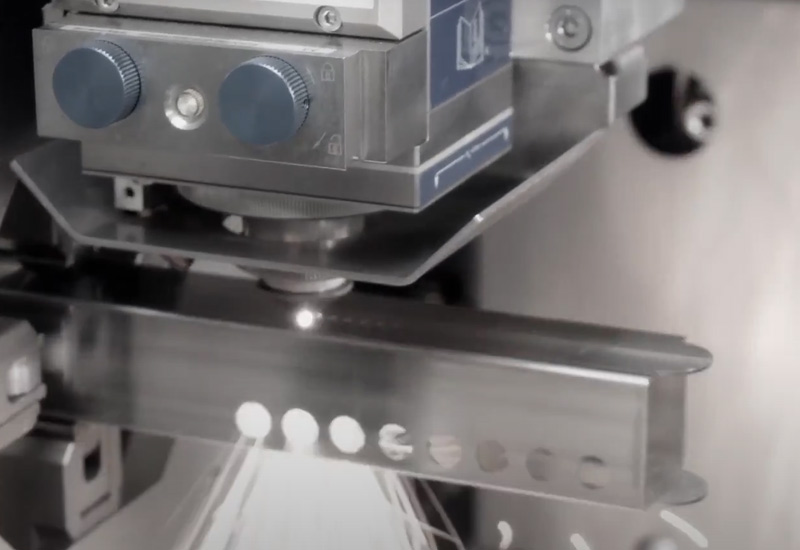

OEM Fiber Laser Cutting Machine for Office Furniture Frames

OEM fiber tube cutting for office furniture frames—clean joints, faster changeovers, better finish. BOGONG LASER: certified manufacturer with global project support.

You build office furniture frames for different scenarios. Frames see coffee spills, rolling chairs, shaky desks, and constant moves. So your tube joints, holes, and edges must be clean, repeatable, and fast to assemble. That’s exactly where an OEM fiber Laser Cutting Machine earns its keep.

Why tube lasers fit office furniture frames

Office frames mostly live in tubes and profiles—square, round, rectangle, sometimes open shapes. The more you design joints into the cut, the less you need jigs, rework, and extra fixtures later.

With fiber laser tube cutting, you can cut:

Tab-and-slot features for snap-fit location before weld.

Copes / fish-mouths for clean tube-to-tube mating.

Bevels to prep edges for weld penetration, no manual grinding.

Locating slots for hardware, cable runs, and hidden connectors.

Decorative perforations that make the product look premium out of the box.

This is why many OEMs shift from saw-plus-drill to one-hit laser, then weld, then powder. Fewer setups, fewer chances to mess things up.

Common cases

Desk frame cell: switching from chop-saw + drill to tube laser reduces clamp swaps and manual scribing. Assemblers say parts “find each other” because tabs and slots align by design.

Chair base frame: fish-mouth cuts remove fit-up guesswork. Welders stop chasing light gaps. Spatter down. Grind time down.

Storage frame with doors: hidden slots and clean bevels help hinges land right the first time; doors close flush without shim.

Automation that matches OEM rhythm

Frequent changeover, small batches, late ECOs. The machine needs to keep up.

Bundle/automatic loading keeps raw tubes flowing without babysitting.

Program change in masked time means you load the next job while the current pipe still cutting.

Automated sorting drops parts to the right bins so downstream doesn’t hunt.

“Design in the cut” beats “fix it at the bench”

When you add the joint into the cut (tabs, indexing slots, bevels), two things happen:

Assembly becomes DFA (Design for Assembly): parts self-locate.

Quality becomes repeatable: go/no-go gauges actually mean something, because your datum is baked into the cut profile.

Cut edge quality = brand look

Office furniture sells on first glance. Clean cut edges mean less deburr, less dressing at weld, and a better powder coat finish. And yes, HAZ is tight with fiber; edges look crisp. You get that “this is made well” vibe without extra polish time.

Plate parts too? Combine flows

Most frame programs mix tube and sheet. You can keep flows separate, sure. But many shops win by aligning programming rules and file naming across both, or by picking combo capability when it makes sense. Fewer hand-offs, fewer chances to lose a part between cells.

The right machine we recommended

آلة قطع الأنابيب بالليزر ذات التحميل الأوتوماتيكي — for unattended bundles, stable takt, and less operator fatigue.

ماكينة قطع الألياف الليزرية المائلة بالليزر — cut bevels right in the program; prep welds without manual grinding.

Laser Plate & Tube Combo Fiber Laer Cutting Machine — consolidate sheet + tube workflows when your mix demands it.

آلة قطع الألياف بالليزر — general fiber platform for a clean, scalable cut process.

Bonus for R&D cells: ماكينة القطع بالليزر الليفي 5050 — compact footprint, tight cuts for fixtures/prototypes.

Quick comparison: manual vs laser on common frame features

| Frame Feature | Typical Manual Ops (summary) | Fiber Laser Ops (summary) | What You Feel Downstream |

|---|---|---|---|

| Cross-tube cope | Saw, grind, template | Single programmed cope | Fit-up snaps in, less gap |

| Bolt hole cluster | Center punch, drill, deburr | Cut holes in-cycle | Holes land true; jig time cut |

| Bevel prep | Angle grinder, rework | Programmed bevel | Faster weld travel, cleaner bead |

| Cable slot | Drill + slot cut + file | Slot in-cycle | No sharp edges, no refile |

| Decorative pattern | Drill/punch + deburr | Pattern in-cycle | Better powder look, fewer rejects |

OEM pain points → what a Laser Cutting Machine actually fixes

| نقطة الألم | What’s Going Wrong | What Fiber Laser Changes | Shop Talk |

|---|---|---|---|

| Changeovers eat day | New jigs, new clamps, slow ramp | Masked-time program swap | “Next job already waiting” |

| Weld rework | Big gaps, mis-located holes | Tabs/slots and tight copes | “No more chase the joint” |

| Scrap high | Ugly remnants, bad bar lengths | Better nesting + drop planning | “Yield finally sane” |

| Slow first-article | Fiddle until it fits | CAD→CAM→cut, one pass | “FAI done before lunch” |

| Brand look flat | Edges rough, paint not happy | Crisp edge, clean HAZ | “Looks premium, for real” |

Selection checklist

| Topic | What to check | Why it matters |

|---|---|---|

| Tube handling | Bundle loader, single-bar mode, re-grip logic | Stable takt, fewer jams |

| Chuck/collet | Grip length, anti-slip, short remnant mode | Safety + yield |

| Bevel cutting | True bevel paths, lead-in/lead-out control | Weld prep accuracy |

| CAM/Nesting | Tube nesting, kerf comp, auto-tab | Scrap control, consistency |

| Sort & label | Bin mapping, QR/label print | Assembly traceability |

| Service & training | Remote diag, spares lead time | Less downtime, faster ramp |

| Compliance | CE, ISO9001, SGS, FDA notes | Clean audits, global sale |

Why BOGONG LASER

BOGONG LASER® runs as a global Laser Cutting Machine Manufacturer and Laser Cutting Machine Factory serving B2B customers across metalwork, automotive, signage, electronics, and more. You get OEM/ODM options, plus certifications that buyers and auditors recognize—CE, ISO9001, SGS, FDA—so plant compliance reviews go smooth. The portfolio covers fiber/CO₂ cutting, marking/engraving, cleaning, welding, and combo setups. That means you don’t outgrow the ecosystem when your pipeline shifts.

Final take

If your team is assembling metal frames all week, a fiber آلة القطع بالليزر for tubes isn’t a luxury. It’s the difference between “always behind” and “on beat.” Design the joint into the cut, automate the boring bits, and protect your edge quality. That’s how you get frames that look right, build fast, and keep margins calm.

Please fill out the contact form. We reply fast.