-

طريق شونهوا، مدينة جينان، شاندونغ

ماكينة الوسم بالليزر للورق TESA

وسم بالليزر عالي الدقة على ورق TESA لملصقات مقاومة للتلاعب. نتائج سريعة ونظيفة ودائمة. بوغونغ ليزر - مُصنِّع ماكينات معتمد عالميًا.

ما هي ماكينة الوسم بالليزر، حقًا؟

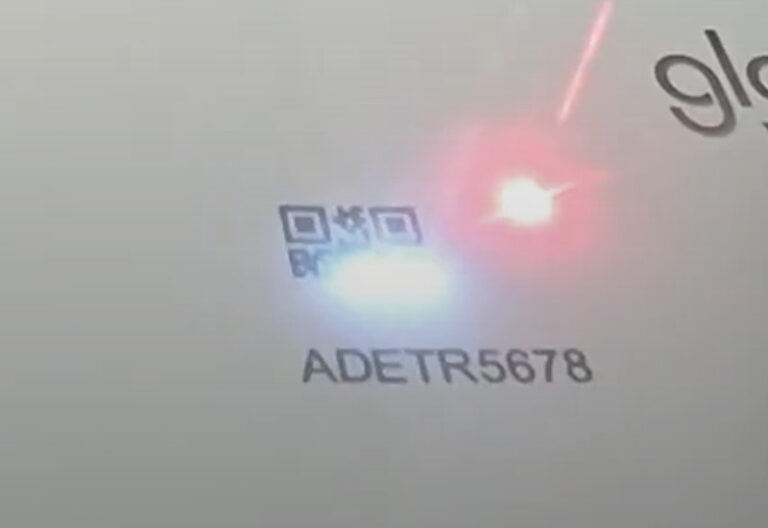

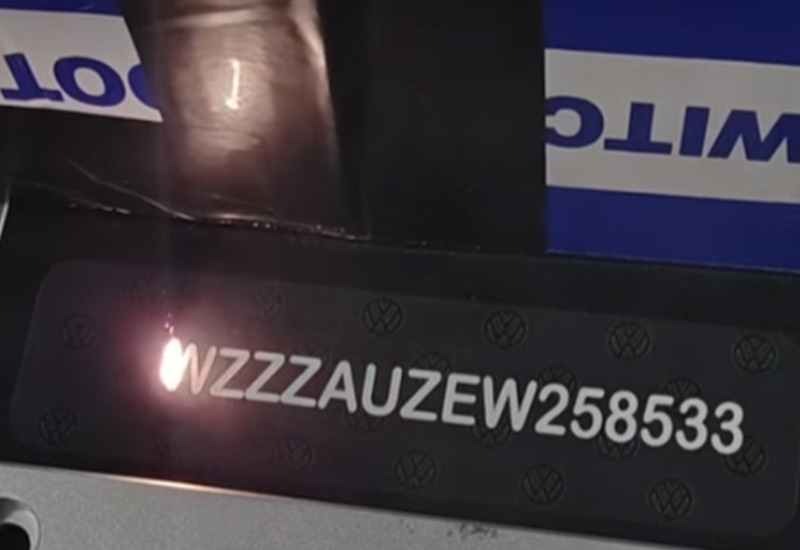

آلات الوسم بالليزر ليست أدوات طباعة عادية. فهي لا تحتاج إلى حبر أو أحبار أو شرائط فوضوية. بدلاً من ذلك، فإنها تستخدم شعاع ليزر مركّز - الأشعة فوق البنفسجية أو الألياف أو ثاني أكسيد الكربون - "لحرق" العلامات مباشرة على سطح المواد. فكر في الأرقام التسلسلية أو الرموز الشريطية أو الشعارات أو رموز QR الصغيرة. إنه سريع ونظيف ودقيق للغاية.

لا يوجد تلامس مع السطح، مما يعني عدم وجود تلطيخ أو تمزق. ولأنك لا تشتري المواد الاستهلاكية باستمرار، فهي أكثر فعالية من حيث التكلفة على المدى الطويل.

في بوغونغ ليزر، نحن نقدم مجموعة كاملة من ماكينات الوسم، بما في ذلك:

ماكينات الوسم بالليزر الليفي للمعادن والبلاستيك عالي التباين

ماكينات الوسم بالليزر بالأشعة فوق البنفسجية للمواد الحساسة مثل الأفلام أو الملصقات

أقلام تحديد بالليزر CO₂ CO₂ للأسطح العضوية مثل الخشب والجلد والزجاج

لكل منها نقاط قوتها، ويعتمد اختيار النوع المناسب على استخدامك. ولكن عندما يتعلق الأمر بورق ملصقات TESA؟ هنا تصبح الأمور أكثر تحديداً.

كيف ينقر ورق TESA والليزر بالليزر فقط

إن ورق TESA ليس ورقًا عاديًا - إنه حل لصق عالي التقنية ومقاوم للعبث مصمم للبيئات القاسية. ستراها عالقة على كل شيء من أجزاء المحرك إلى لوحات الدوائر الكهربائية إلى الأدوات الطبية. إنه مصنوع لمقاومة المواد الكيميائية والحرارة والأشعة فوق البنفسجية وحتى الإزالة.

إذًا لماذا يعمل الوسم بالليزر بشكل جيد عليها؟ ها هي المطابقة:

| ميزة ملصق TESA | أفضل ما يفعله الليزر |

|---|---|

| هيكل غشاء مزدوج الطبقة | يكشف الليزر عن الطبقة السفلية المخفية مع التباين |

| أنواع لامعة وغير لامعة ومعدنية وغير لامعة | ليزر الألياف والأشعة فوق البنفسجية يتكيف مع التشطيبات المختلفة |

| الطبقات الواضحة للعبث | لا يضر الليزر بعلامات الالتصاق دون رفعها |

| النص المصغر أو مصفوفة البيانات | تُنشئ الحزم الدقيقة تفاصيل دقيقة للغاية |

وإليك أفضل جزء - لا يوجد احتكاك. لا خدش. لا نزيف حبر. فقط الدقة.

هل تريد رؤيته أثناء العمل؟ دعنا نشاهد فيديو.

أهم فوائد وضع العلامات بالليزر على ورق TESA

إليك سبب تخلي الناس عن الطابعات النافثة للحبر والتحول إلى الوسم بالليزر لورق TESA:

1. عملية نظيفة وخالية من المواد الكيميائية

يتخطى الوسم بالليزر المذيبات أو الأحبار أو المواد اللاصقة. الأمر كله يتعلق بالحرارة والضوء - لا شيء يلمس السطح. وهذا مهم بشكل خاص في بيئات الغرف النظيفة مثل الإلكترونيات أو الأدوية.

2. الوسم عالي السرعة لعمليات التشغيل بكميات كبيرة

يمكنك وضع علامة آلاف الملصقات في وردية واحدة-لا وقت تجفيف ولا تلطيخ. يقوم بعض عملائنا بتشغيل محددات ألياف الليزر الليزرية بقدرة 30 وات في دورات الإنتاج على 3 نوبات عمل، وبالكاد تلمس الماكينات للصيانة.

3. مقاوم للتلاعب وقابل للتتبع

نظرًا لأن ملصقات TESA غالبًا ما تستخدم طبقات قابلة للتدمير أو يتغير لونها عند وضع علامة عليها، فإن النقش بالليزر يجعل التزوير شبه مستحيل. إضافة الرقم التسلسلي المخفيأو نص صغير، أو رمز شبح؟ الآن لديك إمكانية تتبع حقيقية.

تحقق من هذا العرض التوضيحي.

4. تباين عالٍ، علامات واضحة في كل مرة

الليزر لا "يحرق" فقط. إنه ينقش بتباين - داكن على الضوء، أو فاتح على الظلام، أو حتى تحولات لونية حسب بنية الملصق. رائع للرموز ثنائية الأبعاد والرموز الشريطية التي يتم مسحها ضوئيًا في الخدمات اللوجستية.

| الميزة | مزايا وضع العلامات على ملصق TESA |

|---|---|

| دقة تصل إلى 0.01 مم | يعالج النصوص المجهرية والشعارات والمسلسلات الدقيقة |

| سرعة تصل إلى 300 مم/ثانية | يطابق سرعات الخط الناقل في الوقت الفعلي |

| لا توجد مواد استهلاكية | انخفاض التكاليف على المدى الطويل، وعدم وجود نفايات |

| تركيز بؤري تلقائي ومحور Z الديناميكي | وضع العلامات على أوراق الملصقات غير المستوية أو المنحنية |

| التتبع المتكامل للبرامج | البيانات المتغيرة والترميز الشريطي وأتمتة الطوابع الزمنية |

بوغونغ آلات النقش بالليزر الليفي ثلاثية الأبعاد جيدة بشكل خاص لهذه الأنواع من التطبيقات.

سيناريوهات الصناعة الحقيقية باستخدام الليزر على ملصقات TESA

يُستخدم ورق TESA في مختلف القطاعات. ويفتح الوسم بالليزر الكثير من القيمة - خاصةً عندما تكون إمكانية التتبع والسرعة ومتانة الملصق من الأمور الضرورية.

الأجهزة الطبية والأدوات الجراحية

في المستشفيات والمختبرات، إمكانية التتبع هي كل شيء. تظل ملصقات TESA المميزة بأشعة الليزر فوق البنفسجية قابلة للقراءة بعد التعقيم الذاتيوالمسح بالكحول، وحتى سنوات من التخزين.

تساعد علامات TESA الموسومة بالليزر على رفوف فحص الدم في مطابقة القوارير مع المرضى دون أي تلامس بالحبر أو تلطيخ.

صناعة الطيران والفضاء

المحركات، والأسلاك، وأغطية المستشعرات، سمِّ ما شئت. يجب وضع ملصقات على كل جزء، ويجب أن تبقى تلك الملصقات سارية تقلبات درجة الحرارة، والزيت، والضغط.

استخدم أحد عملائنا قلم تحديد الألياف الليزري الليزري المحمول باليد لتمييز حزم الأسلاك برموز QR مخصصة في منتصف التجميع - لا انحشار للورق ولا أخطاء في الطباعة.

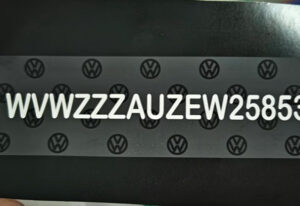

مكونات السيارات

المحركات ووحدات التحكم الإلكترونية والمصدات والمكابح - جميع القطع تتحرك عبر سلاسل توريد طويلة. تجعل ملصقات TESA الحياة أسهل للموردين وفنيي التصليح عندما تظهر هذه القطع.

ساعد وضع علامة ليزرية على ملصقات TESA في الحد من الاحتيال في الضمان بمقدار 42% في أحد موردي السيارات من الفئة الأولى.

الإلكترونيات وتصنيع ثنائي الفينيل متعدد الكلور

لا داعي لتلطيخ الملصقات أو تقشيرها. تصمد ملصقات TESA المميزة بالليزر حتى اللحام الموجي وغسل ثنائي الفينيل متعدد الكلورمما يجعلها مثالية للوحات الدارات الكهربائية.

قام أحد العملاء بنقش مسلسلات المكونات وبيانات مكافحة التزييف على فيلم TESA غير اللامع باستخدام قلم تحديد الألياف الليزري الليزري الكل في واحد.

الخاتمة: TESA + الليزر = تركيبة ذكية

تم تصميم ورق TESA للحماية والأداء. ولكنه لا يصل إلى كامل إمكاناته إلا عند اقترانه بنظام الوسم الصحيح.

يوفر لك الليزر ما لا تستطيع الطباعة توفيره: المتانة والسرعة ودقة عدم التلامسوأتمتة نظيفة. لا يوجد حبر، ولا أجزاء تتآكل، ولا استبدال كل بضعة آلاف من الملصقات.

توفر BOGONG LASER ماكينات مصممة خصيصًا لوسم الورق TESA - مع شهادات CE، وFDA، وSGSوالحلول المخصصة، والدعم في أكثر من 160 دولة. سواء كنت تقوم بوضع علامات على 100 ملصق في الأسبوع أو 10,000 ملصق في اليوم، فلدينا حل يعمل - وينمو - معك.

ابدأ باستكشاف خياراتك هنا:

🔗 استكشف ماكينات الوسم بالليزر

]