-

Дорога Шуньхуа, місто Цзінань, провінція Шаньдун

Постачальник машин для ультрафіолетового лазерного маркування

Шукаєте надійного постачальника машин для УФ-лазерного маркування? BOGONG LASER пропонує точні, економічно ефективні рішення для таких галузей, як медицина, електроніка та автомобільна промисловість.

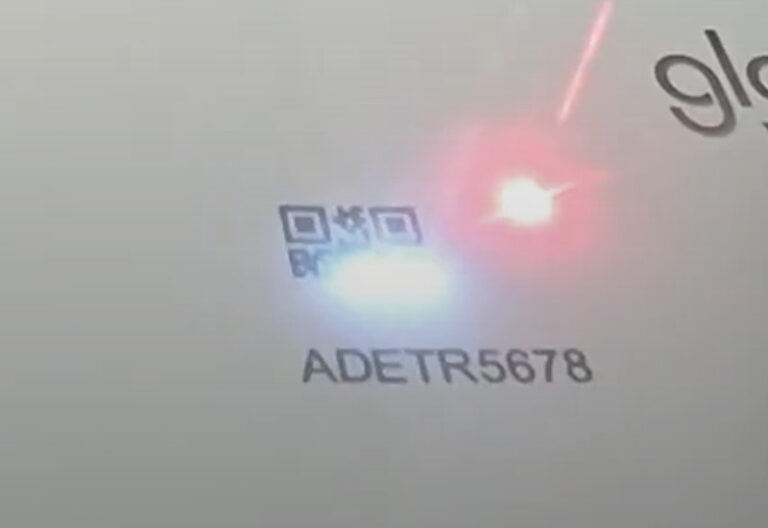

Машини для УФ-лазерного маркування - це "прецизійні інструменти" для галузей, де крихітні деталі створюють або руйнують продукцію. Потрібно нанести QR-код розміром менше кунжутного насіння на мікрочіп? Або вигравіювати термін придатності на медичній упаковці, не пошкодивши матеріал? Ось де УФ-лазери сяють - в буквальному сенсі. Ось як це робиться БОГОНГ ЛАЗЕР пропонує рішення, які дійсно працюють, підкріплені реальними цифрами та складними проблемами на місцях.

1. Що УФ-лазери роблять найкраще

УФ-лазери (довжина хвилі 355 нм) не спалюють, не плавлять і не деформують матеріали. Натомість вони розривають молекулярні зв'язки, створюючи чіткі позначки. Уявіть собі, що це травлення світлом - без нагрівання, без безладу.

Справжній випадок:

Медичному постачальнику потрібно було промаркувати маски KN95 номерами партій. Традиційні методи залишали сліди або пошкоджували тканину. УФ-лазер BOGONG 3W 5W витравлює постійні коди, сумісні з FDA, з зоною термічного впливу *меншою за 0,01 мм* - без компромісу з безпекою та цілісністю матеріалу. Перевірте їх УФ-лазер для медичного пакування

2. Чому BOGONG LASER виділяється

A. Створено для вибагливих матеріалів

УФ-лазери - це не односторонні поні. Машини BOGONG обробляють50+ матеріаліввід силіконових ремінців для годинників до керамічних друкованих плат. Наприклад:

- Свердління скла: Їх Ультрафіолетовий лазер для скла створює мікронні отвори в об'єктивах камер смартфонів без тріщин, що є критично важливим для постачальників рівня Apple

- Пластмаси та полімери: Мітки на ПЕТ-пляшках залишаються чіткими навіть після 100+ циклів миття в посудомийній машині

B. Швидкість, яка оплачує рахунки

Час = гроші. Лазери BOGONG промислового класу вражаютьШвидкість маркування 7 000 мм/с-Ідеально підходить для великосерійного виробництва друкованих плат. Один виробник автомобільних деталей скоротив час циклу на 40%, використовуючи їх Автоматизована ультрафіолетова лінія.

C. Витрати, які ви не зненавидите

Поговоримо про рентабельність інвестицій:

| Фактор | Ультрафіолетовий лазер BOGONG | Середній показник по галузі |

|---|---|---|

| Використання енергії | 30% Нижній | Стандартний |

| Витрати на обслуговування | 50% Нижній | Високий |

| Гарантія | 3 роки | 1-2 роки |

Переклад: Менше поломок, менші рахунки.

3. Реальні проблеми, реальні рішення

Кейс 1: Приглушення помилок в електроніці

Завод напівпровідників боровся з CO2-лазерами, що розтріскували кремнієві пластини. Перехід на BOGONGУФ-лазер 12 Втусунули дефекти і заощадили 1ТП4Т120К/рік на металобрухт.

Кейс 2: Врятувати обличчя (в буквальному сенсі) в косметиці

Люксовому бренду по догляду за шкірою потрібні були невидимі серійні коди на скляних банках. BOGONG'sУльтрафіолетовий лазер 5 Втвитравлені коди, видимі лише в ультрафіолетовому світлі - більше ніяких потворних чорнильних етикеток.

Кейс 3: Більше ніяких "Де мій інструмент?"

Виробник інструменту використовував BOGONG's 3D УФ-лазер Маркувальна машина для гравіювання QR-кодів на ручках гайкових ключів. Тепер механіки сканують інструменти безпосередньо в інвентаризаційні системи, що знижує рівень втрат на 60%.

4. Вибір партнера по УФ-обробці: 3 речі, які не підлягають обговоренню

Відповідність матеріалів: Чи може він впоратися з вашою найдивнішою підкладкою? (BOGONG протестовано на гумі з титановим покриттям)

Підтримка, що відповідає о 2 годині ночіУсунення несправностей 24/7? Так.

Потенціал модернізації: Потрібно додати штучний зір пізніше? Їх модульна конструкція дозволяє адаптуватися

Порада професіонала: Тест-драйв машин з твій матеріали. BOGONG пропонує безкоштовно випробування маркування зразків.

5. Майбутнє? Менше галасу, більше результатів

УФ-технології не стоять на місці:

- Виявлення помилок за допомогою штучного інтелекту: Прототипи BOGONG позначають зміщені мітки в режимі реального часу, заощаджуючи години контролю якості

- Зеленіші лазери: Нові моделі скорочують енергоспоживання на 20%, що відповідає мандатам ЄС щодо сталого розвитку

Кінець

про те, як УФ-лазерне маркування вирішує такі головні болі, як відходи матеріалів, недотримання нормативних вимог і вузькі місця у виробництві.БОГОНГ ЛАЗЕРдосягає цього за допомогою машин, які працюють краще, служать довше і коштують дешевше.

Готові побачити це наживо? Перегляньте їх Каталог УФ-лазерів або замовити демо-версію.[