-

Дорога Шуньхуа, місто Цзінань, провінція Шаньдун

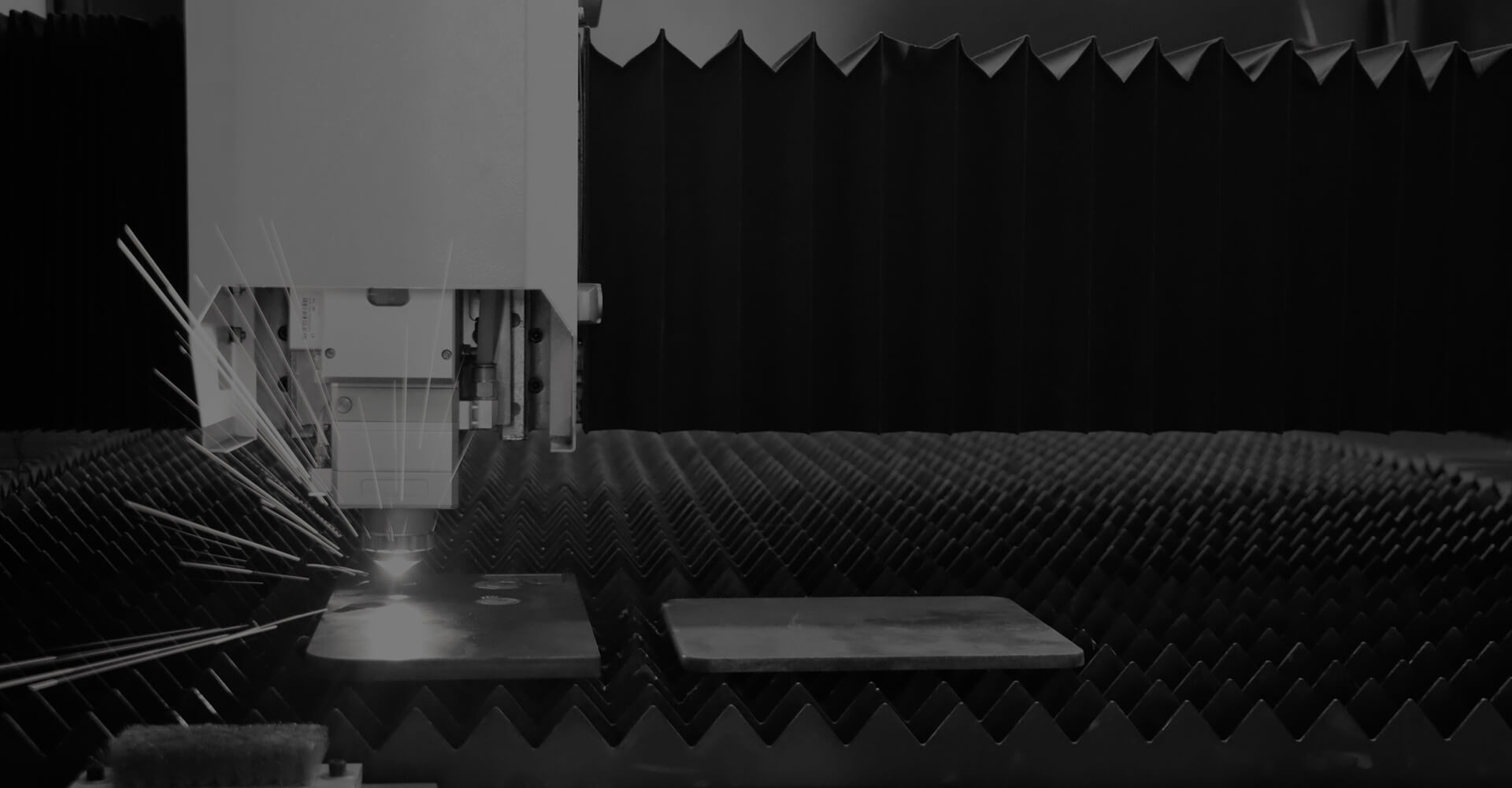

Лазерний верстат для різання металу

Відображаються усі з 9 результатів

5050 Малий волоконний лазерний різальний верстат

6000W-40KW потужна волоконно-лазерна машина для різання металу з лазером для продажу

Лазерний верстат для різання труб з автоматичним завантаженням

Найкращий лазерний верстат для різання металу

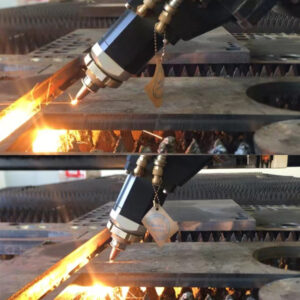

Машина для лазерного різання волоконного конічного різання | Різання канавок, фаски волоконним лазерним різаком

Машина для лазерного різання волокон

Лазерний комбінований волоконно-лазерний різальний верстат для пластин і труб

Найменший верстат для лазерного різання волокон 3020 (300*200 мм)

Найменший волоконний лазерний різальний верстат для латуні, золота, срібла

©Copyright [bogonglaser.com]. BOGONG Laser Machine Supplier All Rights Reserved.