Bir nabız lazer temizleme makinesi çeşitli yüzeylerdeki kirleticileri etkili bir şekilde temizlemek için kısa, kontrollü lazer ışığı patlamaları kullanan yenilikçi bir araçtır. Özellikle metal, cam, seramik ve daha fazlası gibi malzemelerin temizlenmesi için kullanışlıdır. İşte yaygın uygulamalarından bazıları:

- Boya çıkarma: Eski boya katmanlarını zahmetsizce sökün.

- Pas giderme: Yüzeyleri eski haline getirmek için pası ortadan kaldırın.

- Yağ lekeleri ve oksit filmleri: İnatçı yağ lekelerini ve oksit tabakalarını temizleyin.

- Kaynak temizleme: Kirlilikleri gidererek kaynakları finisaj için hazırlayın.

- Otomobil parçası yenileme: Daha iyi performans için otomobil parçalarını onarın ve temizleyin.

- Hassas parça temizliği: Hassas bileşenlerin bütünlüğünü koruyun.

- Elektronik ekipman temizliği: Hassas cihazlara zarar vermeden kirleticileri temizleyin.

Bu makine, çeşitli malzemelerin bakımı ve onarımı için etkili ve hassas bir yol sağlar.

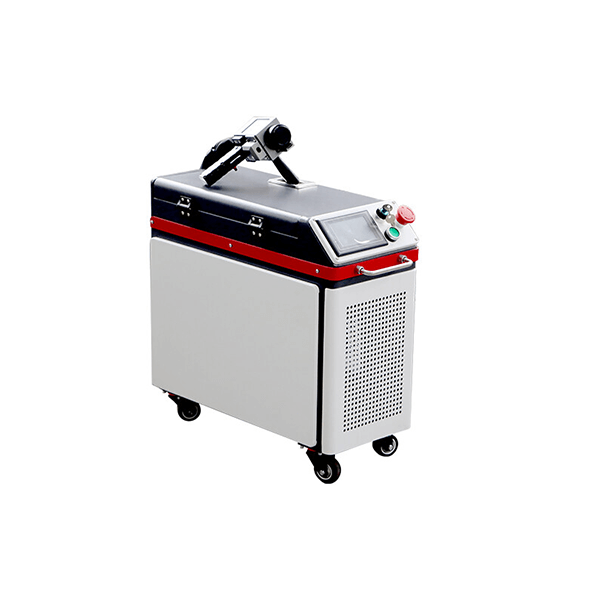

Ana özellik aşağıdaki gibidir:

- Lazer Tipi: Fiber Lazer

Lazer Gücü: 200W 300W

Çıkış Aralığı (Ayarlanabilirse): 0-100%

Darbe Oluşumu: MOPA Q-Anahtarlı (Kalite Faktörü)

Lazer Jeneratörü: JPT/Raycus/Max

Temizleme Alanı: 100*100mm (Opsiyonel 130x130mm, 150x150mm)

Fiber Uzunluğu: 5m

Soğutma Tipi: Hava

Satış Sonrası: 2 Yıl

Pulse Lazer Temizleyicinin Özellikleri

Darbeli Lazer Temizleyici, çift salınımlı akıllı temizleme başlığı kullanarak ve çeşitli uygulamalara hitap etmek için etkileyici bir 8 temizleme modu yelpazesi sunarak sürekli (CW) lazer temizleyicilerden ayrılır. Bu sistem, darbe genişliği ve frekansı gibi parametreleri ayarlayarak giriş gücünü etkin bir şekilde yönetir, iş parçası için optimum sıcaklıkları korurken enerji kaybını en aza indirerek genel verimliliği artırır.

Kullanıcı Dostu Tasarım: Kolaylık düşünülerek tasarlanan bu lazer temizleyici, mekansal sınırlamalar olmaksızın çalışma esnekliği sağlayan 5 metre uzunluğunda bir fiber kablo içerir. BOGONG Lazer Makinesi, biri lazer kafasında diğeri makine kabininde olmak üzere iki dokunmatik ekrana sahiptir ve kolay parametre ayarlamalarına olanak tanır. Genişletilmiş IO arayüzü, otomatik temizleme görevleri için manipülatörlerle sorunsuz entegrasyon sağlar. Ayrıca, bu lazer pas sökücünün kullanıcıları için sorunsuz ve hızlı bir öğrenme eğrisi sağlamak için kapsamlı İngilizce kılavuzlar ve eğitici videolar dahildir.

Tek Modlu Çok Yönlülük: 2mJ lazer temizleme makinesi gibi darbeli tek modlu çalışma, metal yüzeylerin, otomotiv parçalarının, taş, ahşap, plastik ve yüksek güçlü temizlik gerektiren diğer malzemelerin temizlenmesi dahil olmak üzere çeşitli uygulamalar için son derece uyarlanabilir ve uygundur. Özellikle ağır pas, oksit tabakaları ve kalın boya gibi güçlü yapışma özelliğine sahip zorlu işlerin üstesinden gelmede etkilidir.

Çok Modlu Hassasiyet: 15mJ kapasiteli darbeli çok modlu çalışma, hassas parçaların temizlenmesi, elektronik ekipmanların bakımı ve mikro bileşenlerin işlenmesi gibi yüksek hassasiyetli görevler için mükemmeldir. Hafif yapışma, kolayca çıkarılabilen kirleticiler ve hafif pas içeren senaryoların üstesinden gelmek için özel olarak tasarlanmıştır; bu da onu kalıp temizliği gibi hasardan kaçınmanın kritik olduğu uygulamalar için ideal bir seçim haline getirir.

Neden Bogong Lazer Temizleme Makinesi seçilmeli?

- Lazer temizleme teknolojisindeki kapsamlı deneyimimizle, özel gereksinimlerinizi karşılamak üzere özelleştirilmiş gelişmiş çözümler sunma konusunda uzmanız. Uzman mühendis ve teknisyenlerden oluşan ekibimiz, derin endüstri bilgisine sahiptir ve ideal çözümü almanızı sağlar lazer temizleme makinesi benzersiz uygulamalarınız için uyarlanmıştır.

- Pası gidermek, boyamak vb. için zaten parametre kaydediyoruz, aldıktan sonra kolayca lazer temizliğine başlayabilirsiniz.

- Bogong sadece yüksek kaliteli lazer cihazı sağlamakla kalmaz, aynı zamanda geçmiş yıllarda en iyi satış sonrası hizmeti de sunar.

Pulse Lazer Temizleme Makinesi Nasıl Çalışır?

Pulse Lazer Temizleme Makinesi, kirleticileri yüzeylerden etkili bir şekilde çıkarmak için gelişmiş lazer teknolojisini kullanır. İşte nasıl çalıştığına dair kısa bir genel bakış:

- Lazer Emisyonu: Hassas temizlik için kısa enerji patlamaları yayan güçlü bir darbeli lazer ışını üretir.

- Hedefe Yönelik Temizlik: Bir yüzey hedeflendiğinde, lazer enerjisi pas veya boya gibi kirleticiler tarafından emilir.

- Buharlaşma: Emilen enerji kirleticileri hızla ısıtarak alttaki malzemeye zarar vermeden buharlaşmalarına neden olur.

- Seçici Kaldırma: İşlem seçici olarak sadece kirleticileri hedef alır ve yüzeyin bütünlüğünü korur.

- Ayarlanabilir Ayarlar: Çeşitli yüzeyler ve kirlilik seviyeleri için özelleştirilebilir güç ayarları ve odak seçenekleri sunar.

Genel olarak, Pulse Lazer Temizleme Makinesi endüstriyel temizlik uygulamaları için verimli, hassas ve çok yönlü bir çözüm sunar.

Doğru Pulse Lazer Temizleme Makinesi Nasıl Seçilir

Doğru darbeli lazer temizleme makinesini seçmek işiniz için önemli olacaktır, makinenin özel ihtiyaçlarınızı karşıladığından nasıl emin olabilirsiniz. İşte bilinçli bir karar vermenize yardımcı olacak bir kılavuz:

- Malzeme Uyumluluğu: Temizlemeyi planladığınız malzeme türlerini belirleyin (örneğin, pas, boya, metal ahşap, akrilik, vb.). Seçtiğiniz makinenin bu malzemeleri etkili bir şekilde işleyebildiğinden emin olun.

- Lazer Tipi: Farklı lazer tipleri 2mj, 5mj ve 15mj, farklı lazer farklı sonuç.

- Çalışma Alanı Boyutu: Üstlenmeyi planladığınız projelere göre temizlik alanının boyutunu değerlendirin. Makinenin eşyalarınız için yeterli bir çalışma alanına sahip olduğundan emin olun. Doğru F-teta lensi seçin, lütfen bu konuda satışlarımıza danışın.

- Kullanım Kolaylığı: Kolay tasarım ve kullanım sağlayan kullanıcı dostu yazılıma sahip makineleri arayın.

- Müşteri Desteği ve Garanti: Üreticinin destek seçeneklerini ve sunduğu garantiyi araştırın. Güvenilir müşteri hizmetleri, sorun giderme ve bakım için çok önemli olabilir.

Ödeme Koşulları

1. Depozito ve Bakiye: Sevkiyattan önce ödenmesi gereken bakiye ile önceden bir 30% T / T depozitosu gereklidir.

2. Alibaba Ticaret Güvencesi: Ödemeler Alibaba Ticaret Güvencesi aracılığıyla gerçekleştirilebilir.

SSS

Ambalaj Nedir

Makinelerimiz üç katmanlı bir düzende paketlenir. Dış katman ahşap bir kasadan oluşur, orta katmanda sarsıntıya karşı koruma sağlamak için köpük dolgu bulunur ve iç katman su geçirmezlik için kalın bir plastik torba içerir.

Paket Taşıma Sırasında Zarar Görecek mi?

Ambalajlarımızı tüm olası hasar faktörlerini ele alacak şekilde titizlikle tasarlıyoruz ve nakliye acentelerimiz güvenli taşımacılık konusunda deneyimlidir. Başarılı bir şekilde 180 ülkeye ihracat yaptık, bu nedenle paketinizin mükemmel durumda ulaşacağından emin olabilirsiniz.

Müşterilerin çoğu UPS / DHL express ile taşımayı seçmeyi sever, varış noktasına yaklaşık 5-7 gün ulaşabilir, iletişime geçin BOGONG Lazer lazer temizleyici hakkında daha fazla bilgi almak için